Vacuum sludge filling bag

A mud flushing and vacuum technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as lack of sand resources, damage to marine ecology, and high cost of land reclamation to achieve good sealing, improve safety, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

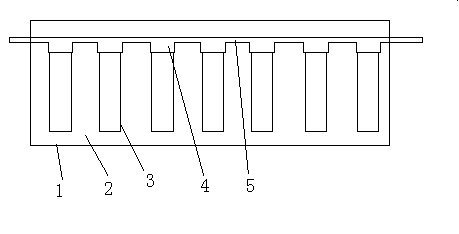

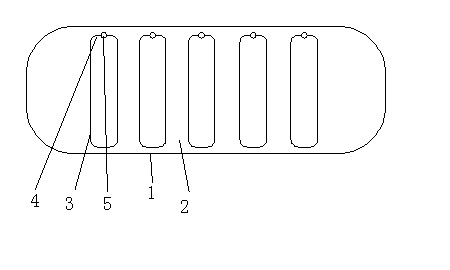

[0011] Example 1, a vacuum flushing mud bag, including a bag body 1 and a sludge 2 filled in the bag body 1, and the bottom of the bag body 1 is uniformly fixed with drainage boards 3 arranged at intervals, and the drainage boards 3 pass through the upper two-hand board joint 4 Connected in a circle, the two-hand board joint 4 is composed of two connecting pipe sections 41, a middle straight pipe 42, and two hollow boxes 43 vertically connected with the middle straight pipe. The drain board 3 is inserted into the hollow box 43, and the two-hand board joint 4 The two connecting pipe sections 41 are connected to the vacuum tube 5.

Embodiment 2

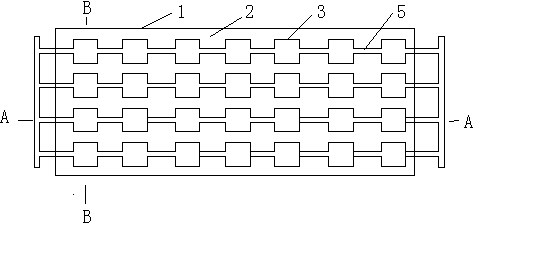

[0012] Example 2, with reference to Example 1, several parallel vacuum tubes 5 are arranged in the bag body 1, and the drainage plates 3 are arranged in several rows and columns, and each vacuum tube 5 communicates with the drainage plates 3 of the same row through the two-hand board joint 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com