Grain humidification system for warehouse

A grain and warehouse technology, applied in the field of warehouse grain humidification system, can solve the problems of continuous watering for a long time, low economic efficiency, excessive watering, etc., achieve adjustable and controllable humidification effect, and significant economic benefits , Humidification uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

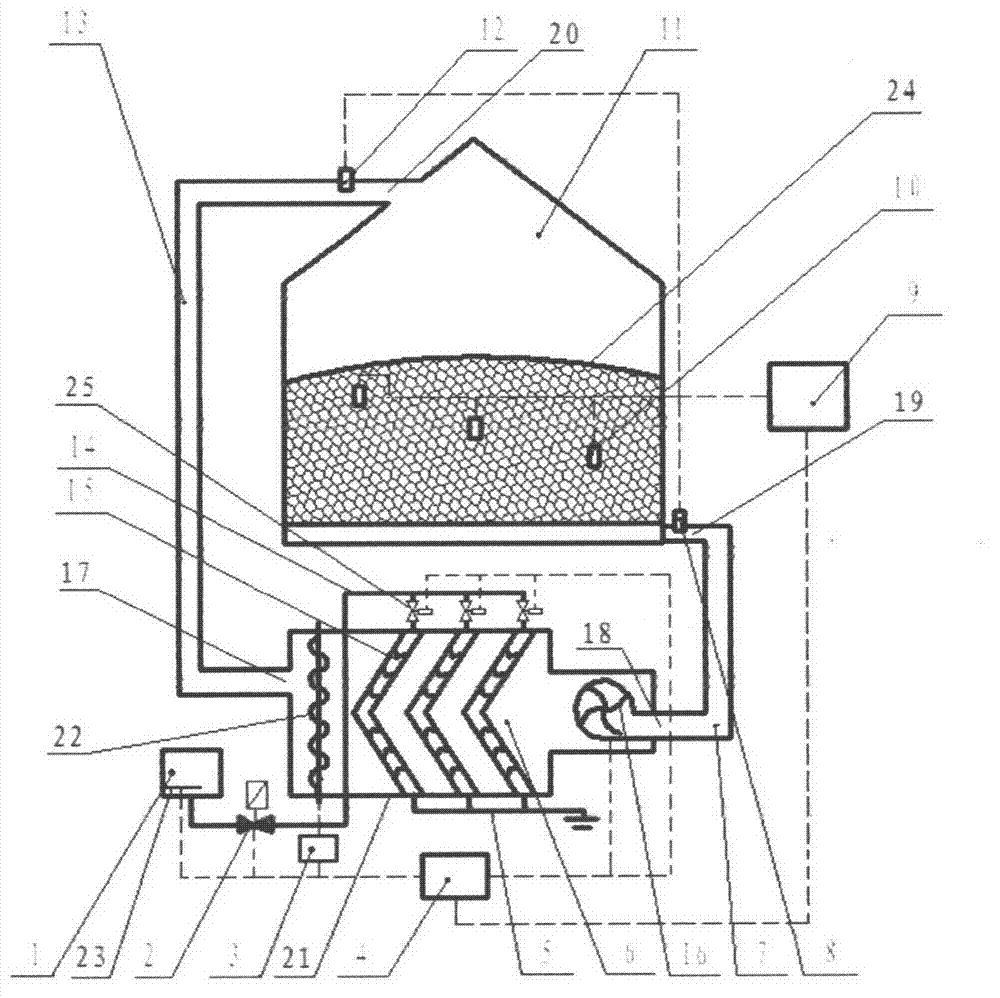

[0015] Referring to the accompanying drawings, the warehouse grain humidification system includes a water curtain heating humidifier 6 connected to a water source, a granary 11 and a temperature and humidity measurement and control system, and the water source is a water tank 1 provided with an electric heater 23; the water curtain heating humidifier 6 An air inlet 17 and an air outlet 18 are provided. The granary 11 is provided with an air inlet 19 and an air outlet 20. The water curtain heating humidifier 6 passes through the air outlet 18, the air inlet 17 and the air inlet 19 and the air outlet 20 of the granary 11. Air ducts 7 and 13 are used to connect with the granary 11 to form an air circulation system; the temperature and humidity measurement and control system is mainly composed of the main controller 9 and the temperature and humidity sensor group and the control actuator 4 connected to the main controller 9 and set in the air circulation system Composition; the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com