High-precision combined photoelectric mast set system

A combined, high-precision technology, used in defensive devices, offensive equipment, etc., to achieve the effect of improving the level of accuracy, raising the working height, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

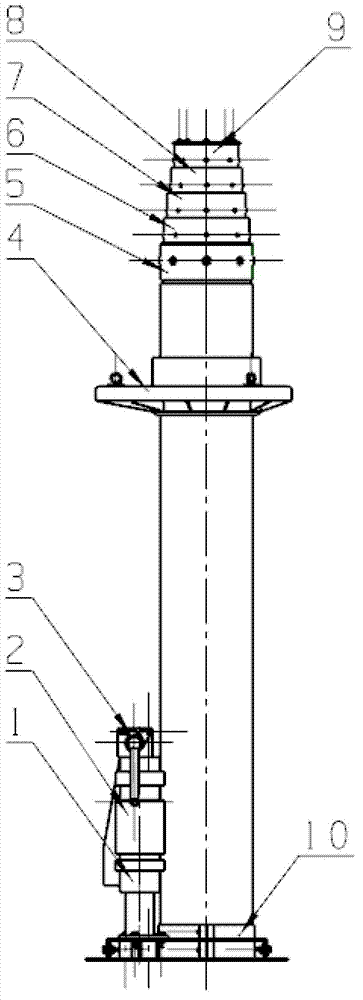

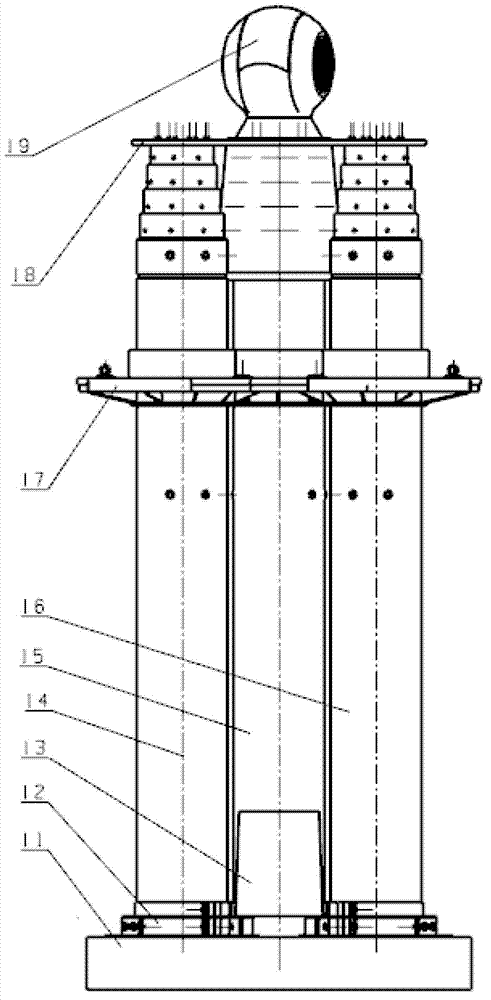

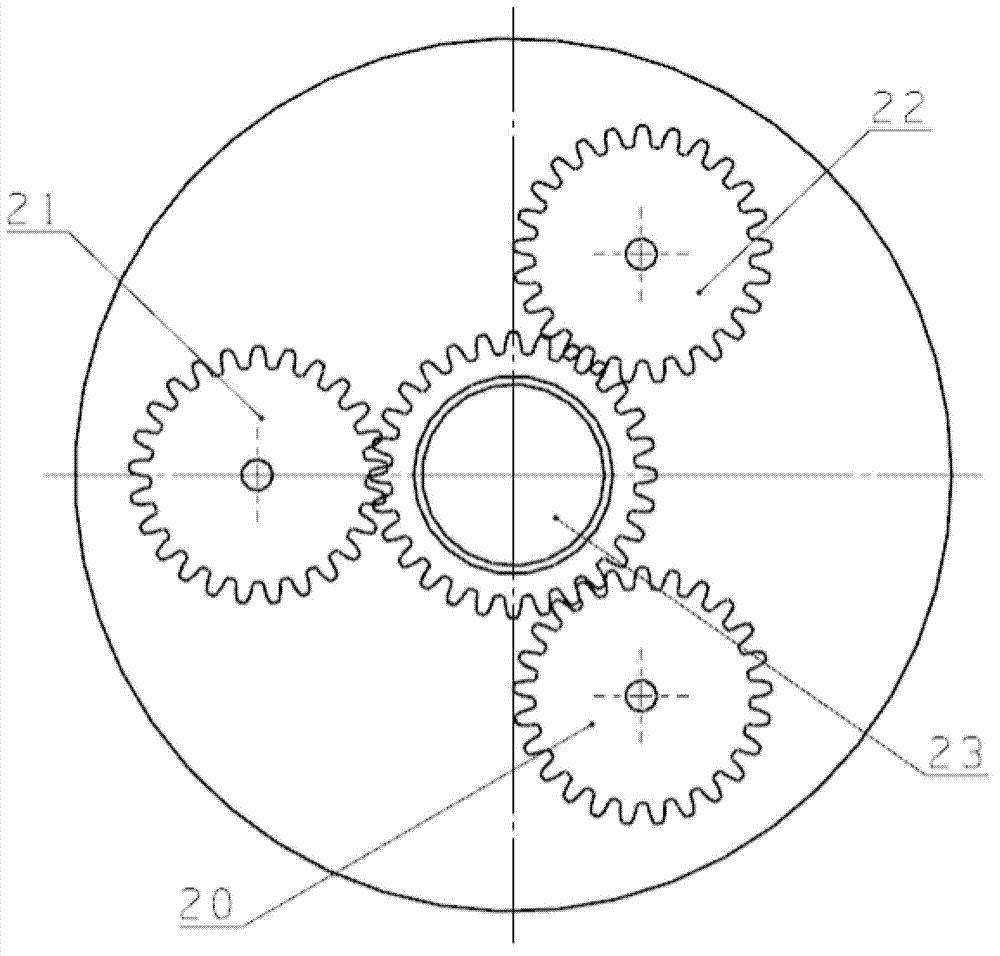

[0013] The invention according to figure 2 , image 3 The shown structural implementation includes the first single mast 14, the second single mast 15, the third single mast 16, the base 11, the mast fixing assembly 12, the torque motor 13, the assembly 17 for fixing and hoisting in the middle of the mast group, The photoelectric countermeasure system installation platform 18; the first single mast 14, the second single mast 15, and the third single mast 16 are fixedly connected with the mast fixing assembly 12 respectively, and are arranged uniformly in a 120° circle. The first single mast 14 1. The second single mast 15 and the third single mast 16 form a single mast group; the mast fixing assembly 12 is fixedly installed on the base 11; the torque motor 13 is fixedly installed in the middle of the mast fixing assembly 12, and the torque motor 13 stretches into the mast The driving gear 23 inside the fixing assembly 12 directly stretches into the first gear 20 inside the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com