System for fastening a rail and guide plate for such a system

A technology for fixing rails and guide plates, applied in the field of systems for fixing rails and guide plates of such systems, can solve problems such as changes in the positions of elastic parts and adapters, and achieve the effect of preventing excessive extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

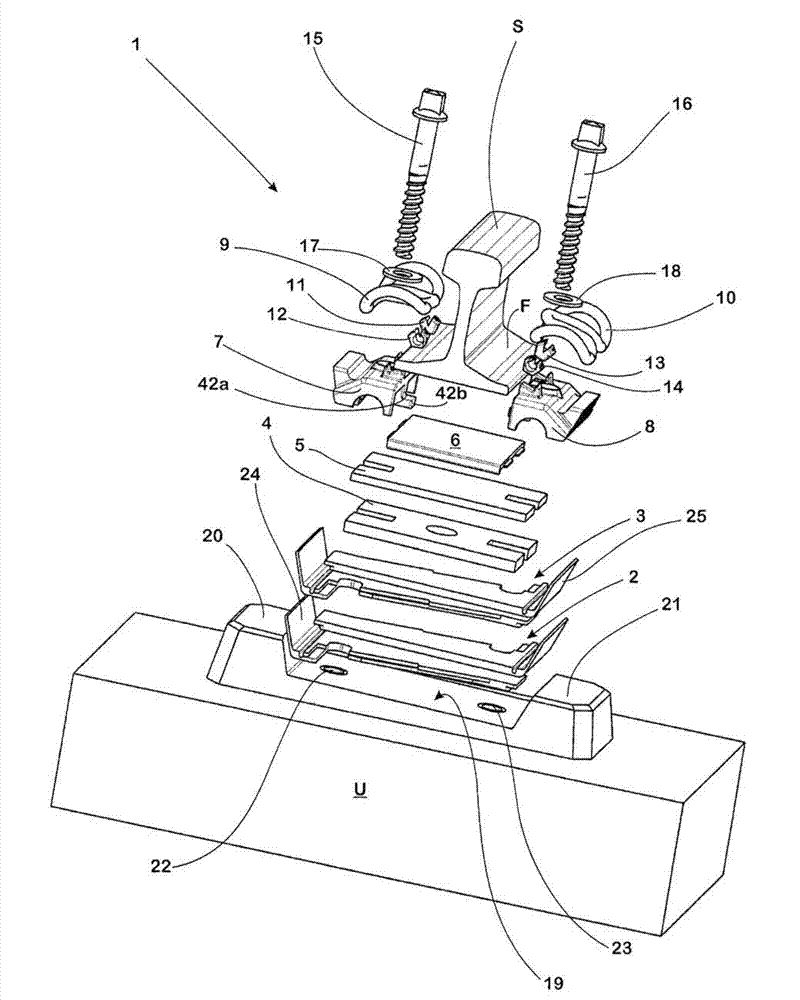

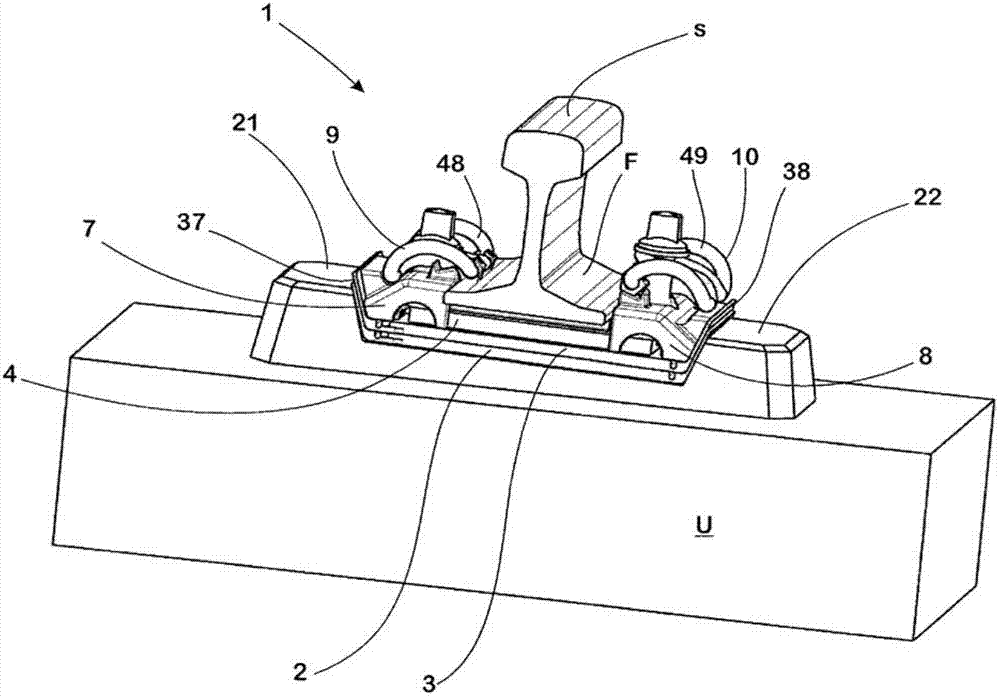

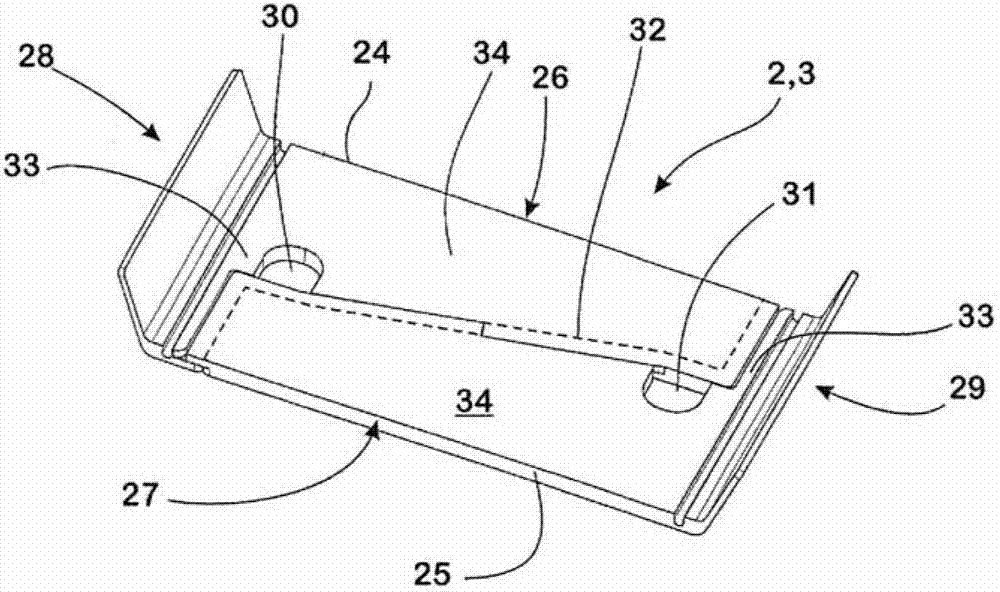

[0091] A system 1 for fixing a track S on a fixed base U formed, for example, of cement sleepers or cement slabs, the system comprising a first backing plate 2, a second backing plate 3, an elastic intermediate layer 4, a pressure distribution plate 5, a height Adjustment plate 6, first guide plate 7, second guide plate 8, two elastic parts 9, 10 formed as ω-shaped clamping clips, two pairs of adapters 11-14 and two clamps formed as clamping bolts Clamping elements 15 , 16 act on the central rings of the spring elements 9 , 10 via washers 17 , 18 .

[0092] The fastening system 1 is seated in a receptacle 19 formed in one piece on the fastening base, which is delimited on its narrow side extending parallel to the rail S by support shoulders 20 , 21 . In the bearing surface of the receptacle 19 present between the support shoulders 20 , 21 , plastic pins 22 , 23 are respectively inserted into the base U adjacent to the support shoulders 20 , 21 . When assembling the system 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com