Coulomb damping features using ultrasonic welding

一种超声波焊接、阻尼的技术,应用在焊接设备、非电焊设备、机械设备等方向,能够解决疲劳寿命降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

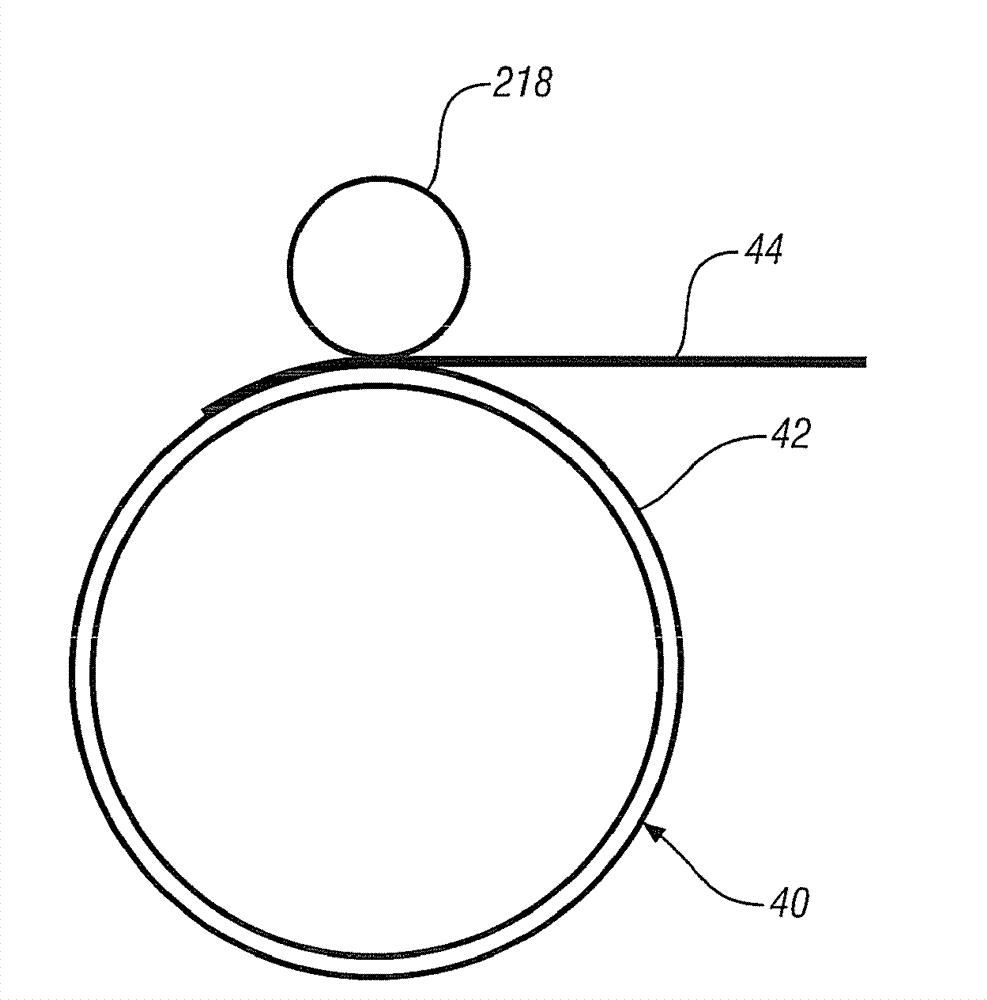

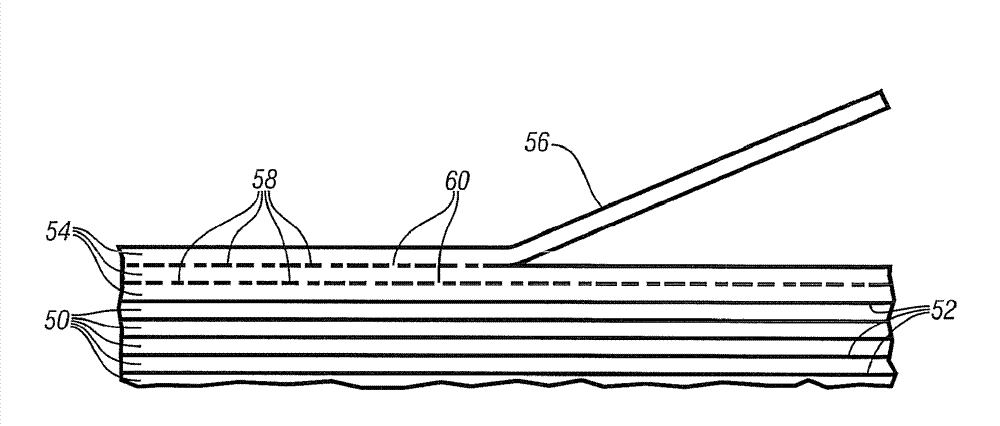

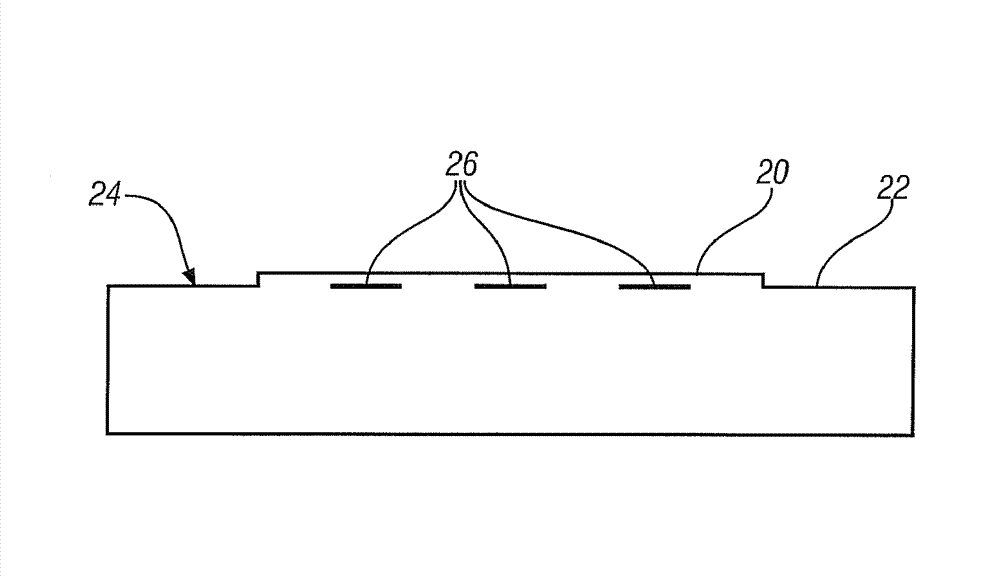

[0019] The present invention uses ultrasonic welding to bond selected surfaces of a foil, tape or strip to a surface of an article with the goal of providing a frictionally damped interface between the partially bonded strip and the adjacent article surface. These frictional damping interfaces are formed in portions of vibratory elements or articles that are determined to be likely to be prone to generating or transmitting undesired vibrations. In other embodiments of the invention, the shock absorbing elements of the article or the entire article may be formed by ultrasonically welding successive layers of metal foils or sheets to construct shock absorbing article segments or articles. In this embodiment, non-welded regions are left between one or more layers of the layered structure to provide the desired amount of frictional damping interface.

[0020] In an exemplary embodiment of the invention, the article may be an electric motor for driving one or more wheels of a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com