Three-ladder seven-step method for baking scattered flue-cured tobacco leaves

A three-step, tobacco-leaf technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that tobacco farmers are not easy to master, farmers lose, and affect farmers' income, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

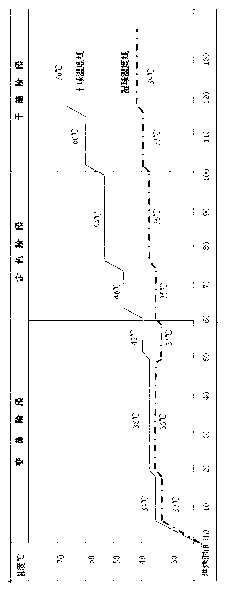

[0018] Example 1, "three-step seven-step method" for drying loose tobacco leaves: Among the seven steps, the yellowing stage is the first three steps, the color-fixing stage is the middle two steps, and the gluten-drying stage is the last two steps. The specific operations are as follows:

[0019] The first step is to set the temperature of the controller at 34°C and the humidity at 33°C; turn on the fan before ignition, and the fan will run idling for 2-5 hours in high winds, then ignite, turn on a low fire, and set the heating rate to 1°C / h. The time is 12 hours; after the ignition, the fan is low-speed and the wind blows, the tobacco leaves are slightly lodging, and the tips of the leaves turn yellow.

[0020] In the second step, set the temperature of the controller at 38°C, and set the humidity at 35°C; burn on medium heat, the heating rate is 1°C / h, and keep it for 20-30h; Turn yellow, the middle and upper part of the smoke is 10% yellow; the leaves are soft;

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com