Plastic tube milling crushing machine

A crusher and plastic pipe technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of unsatisfactory crushing quality and efficiency, high noise and high noise of the new plastic pipe crusher, and achieve milling The process is smooth, the noise is reduced, and the noise is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

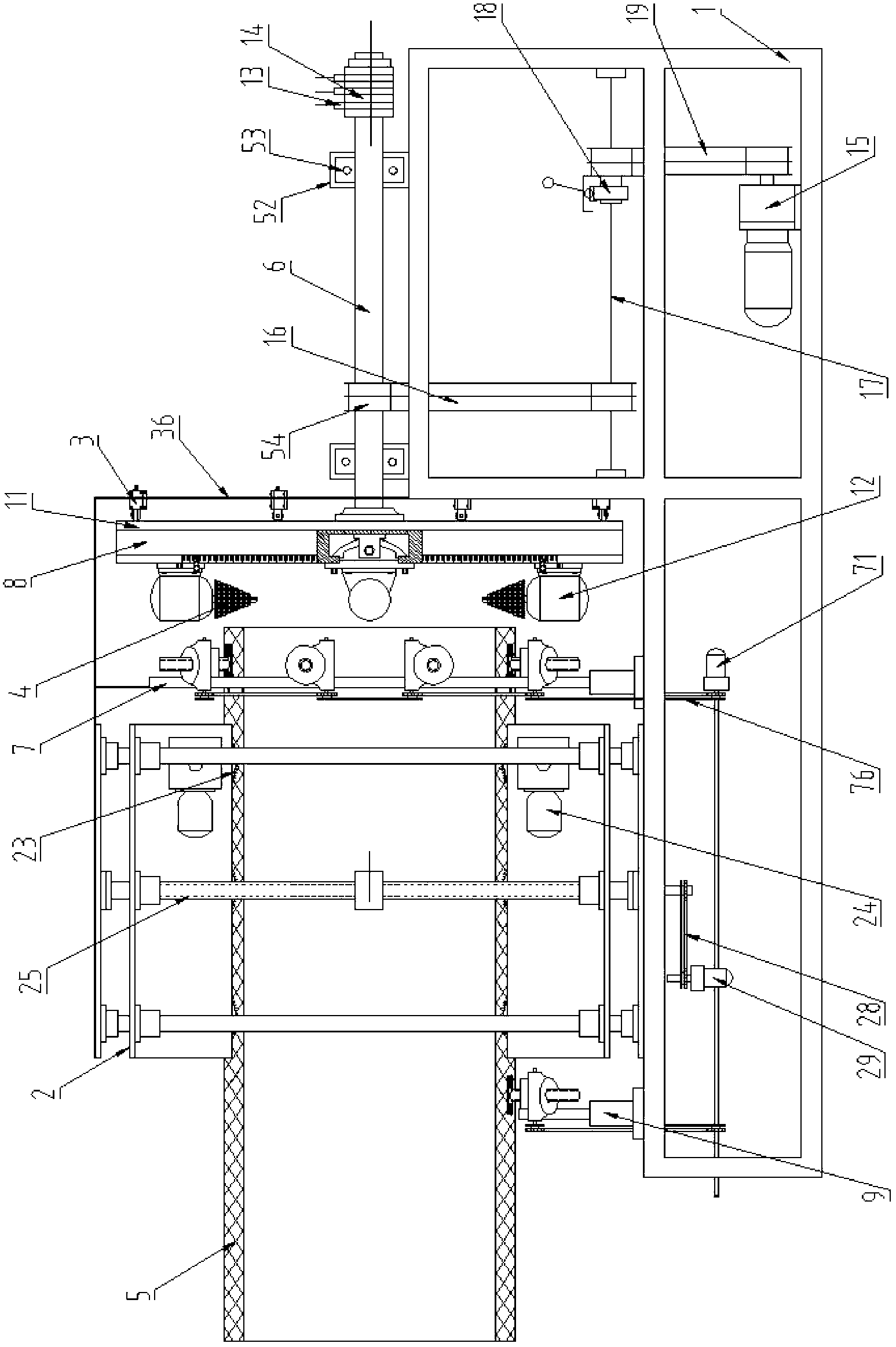

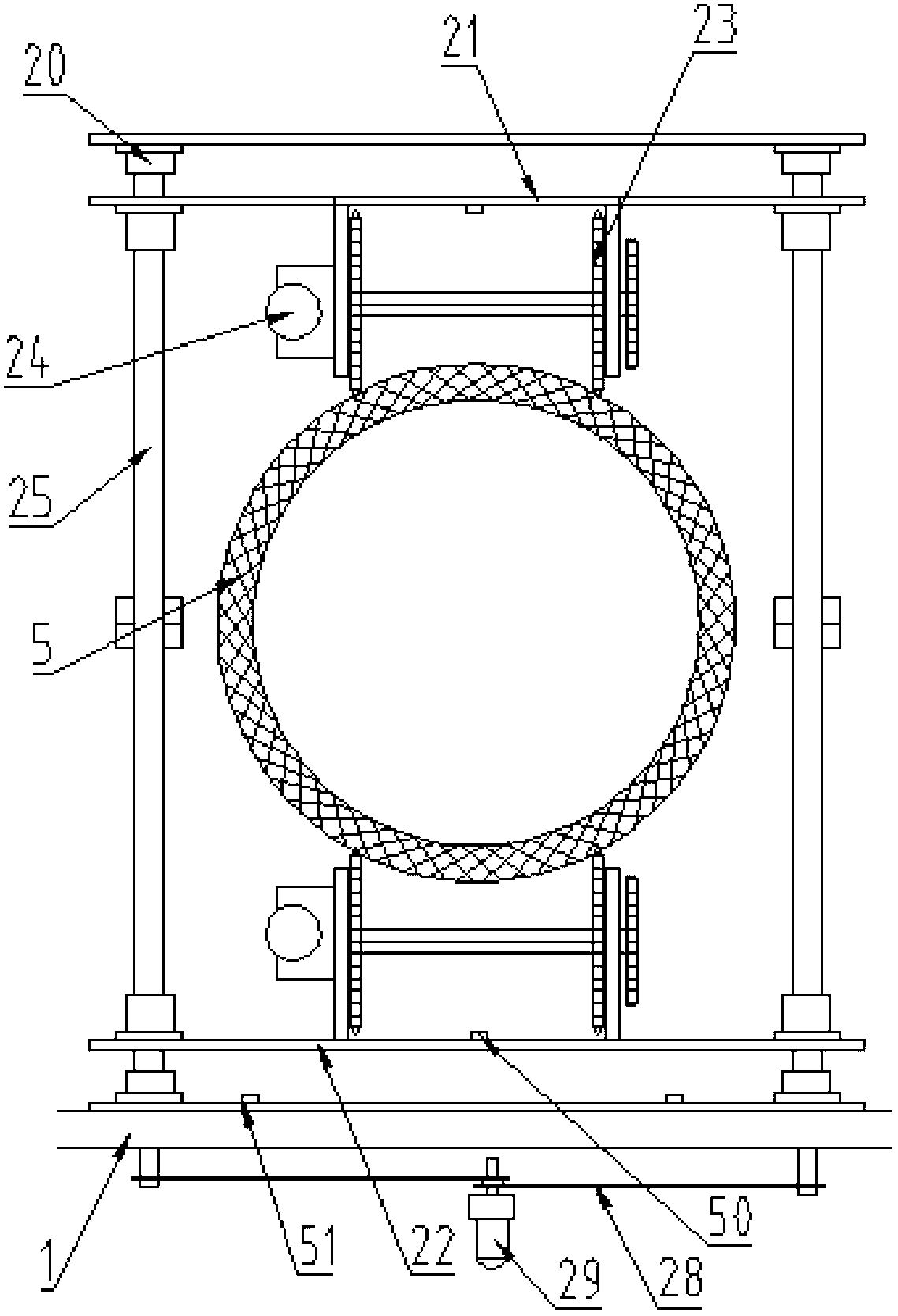

[0038] Such as Figure 1-12 As shown, the present invention provides a plastic pipe milling crusher, comprising a frame 1, a feeding mechanism 2, a pipe stabilizing mechanism 7, a crushing platform and an anti-vibration mechanism 3, the frame 1 is an approximate lathe-type structure, and the feeding mechanism 2 is used for The plastic pipe 5 is clamped and pushed to the pipe stabilizing mechanism 7, and the pipe stabilizing mechanism 7 is also positioning the plastic pipe 5 at the center of the four groups of milling flying knives 4 on the crushing platform for milling while clamping the plastic pipe 5 firmly.

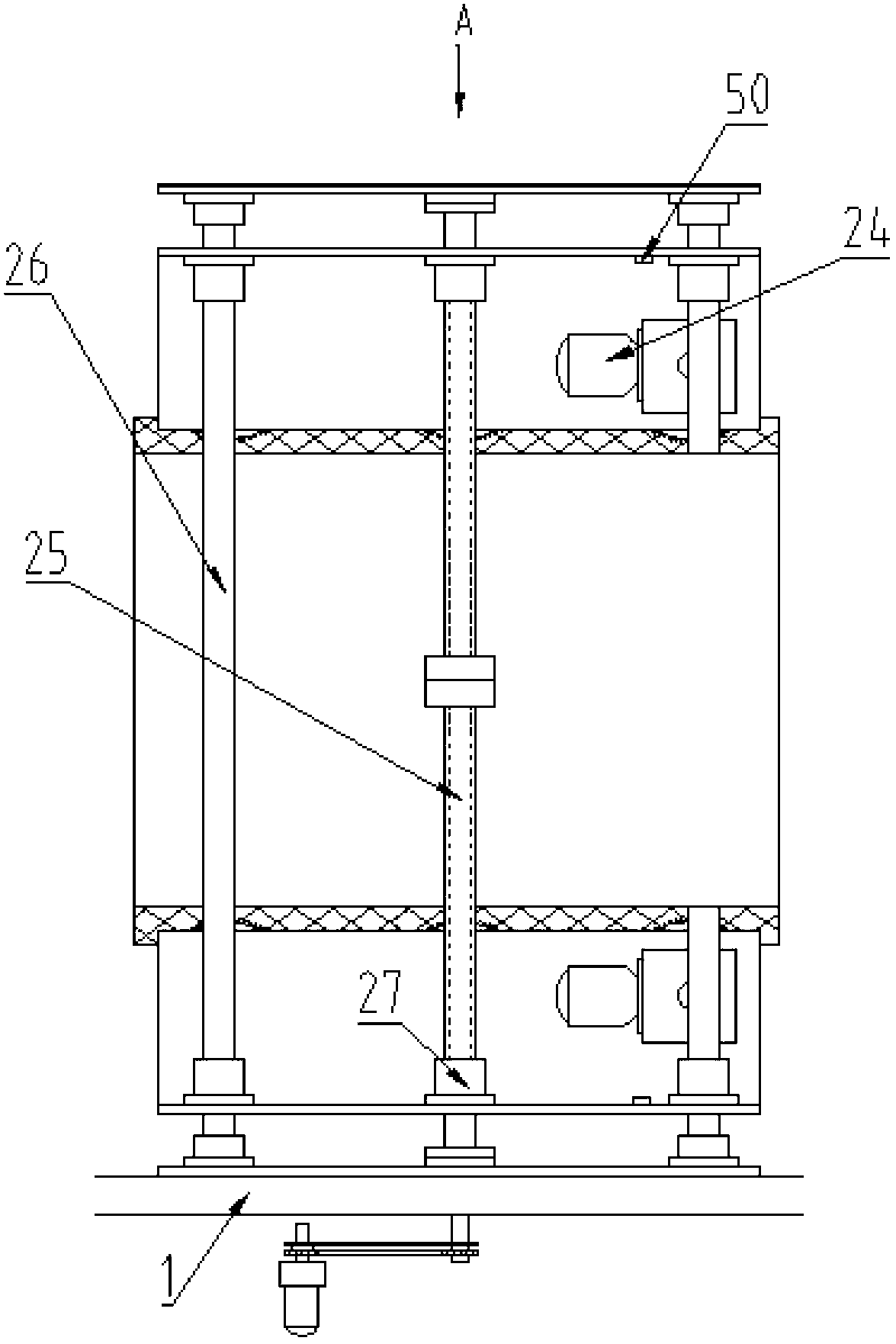

[0039]The feeding mechanism 2 includes an upper mounting plate 21, a lower mounting plate 22, two groups of push tube gears 23 and two feed motors 24 for driving two groups of push tube gears 23 to rotate; a group of push tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com