Electric miter saw

A miter saw, electric technology, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the long slide rail strength, high manufacturing precision requirements, shorten the working space and packaging volume, and the sliding stroke is very small Difficult to make too big and other problems, to achieve the effect of easy cutting and observation, saving working space and reducing packaging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

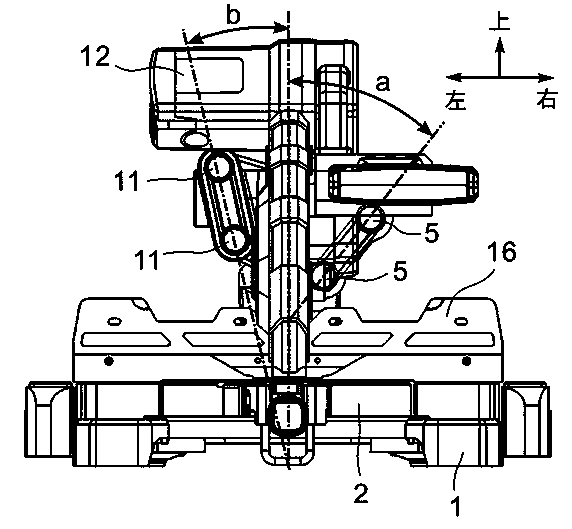

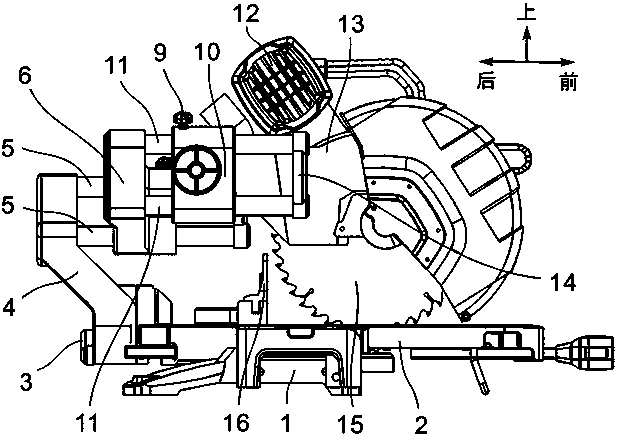

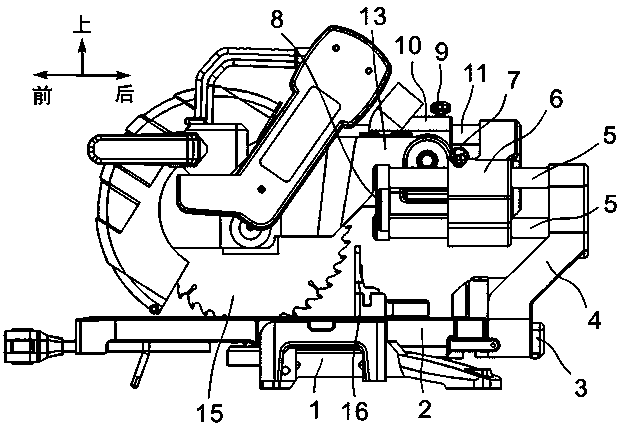

[0046] Such as figure 1 As shown in -4, the electric miter saw of the present invention includes a base 1, a grid 16 installed on the base 1 for positioning workpieces, a workbench 2 rotatably connected to the base 1, and rotatably installed at the end of the workbench 2 The swing arm 4. The swing arm 4 is fixed and locked on the workbench 2 through a swing arm lock button 3, so that the swing arm 4 and the workbench 2 rotate relative to each other to form a set cutting angle.

[0047]The swing arm 4 is provided with two parallel first-layer slide rails 5 extending forward in the horizontal direction, and the first-layer slide rail 5 is provided with a slider 6 that can slide along its horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com