Coil cooler arranged in heating zone

A technology of cooler and heating zone, applied in metal processing, printed circuit and other directions, can solve the problem of water leakage of radiator, and achieve the effect of simple installation method, convenient maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

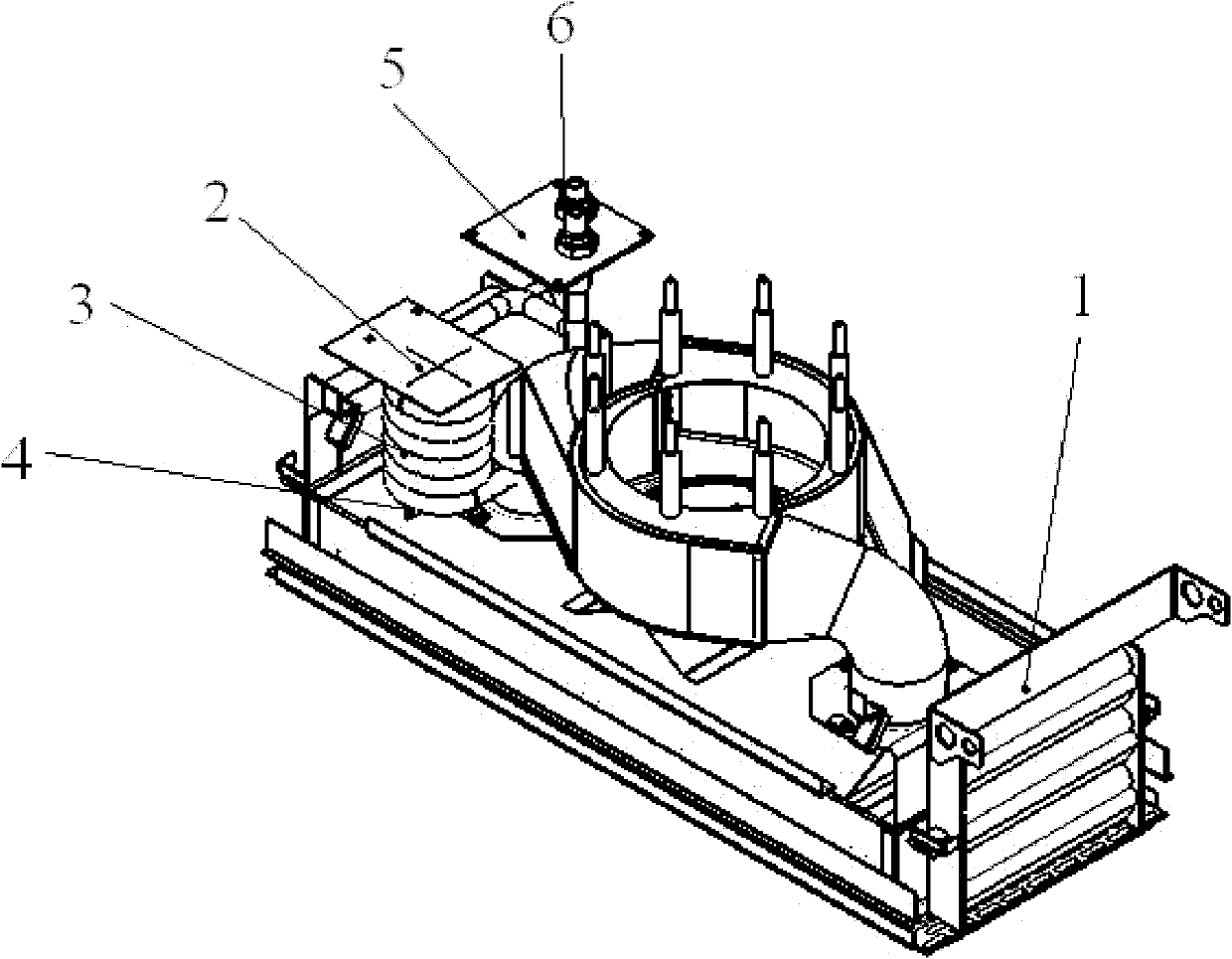

[0022] A coil type cooler arranged in the heating area, its structure is as follows figure 1 As shown, the cooler is set on one side of the heating zone 1 of the reflow oven. The cooler includes a mounting plate 2, a stainless steel hose coil 3, a coil fixing device 4 and a fixing plate 5. The mounting plate 2 is arranged on the stainless steel hose coil 3. Above, the coil fixing device 4 fixedly installs the stainless steel hose coil 3 on the base plate, and the fixing plate 5 is fixed on the side of the stainless steel hose coil 3 through fixing screws 6 .

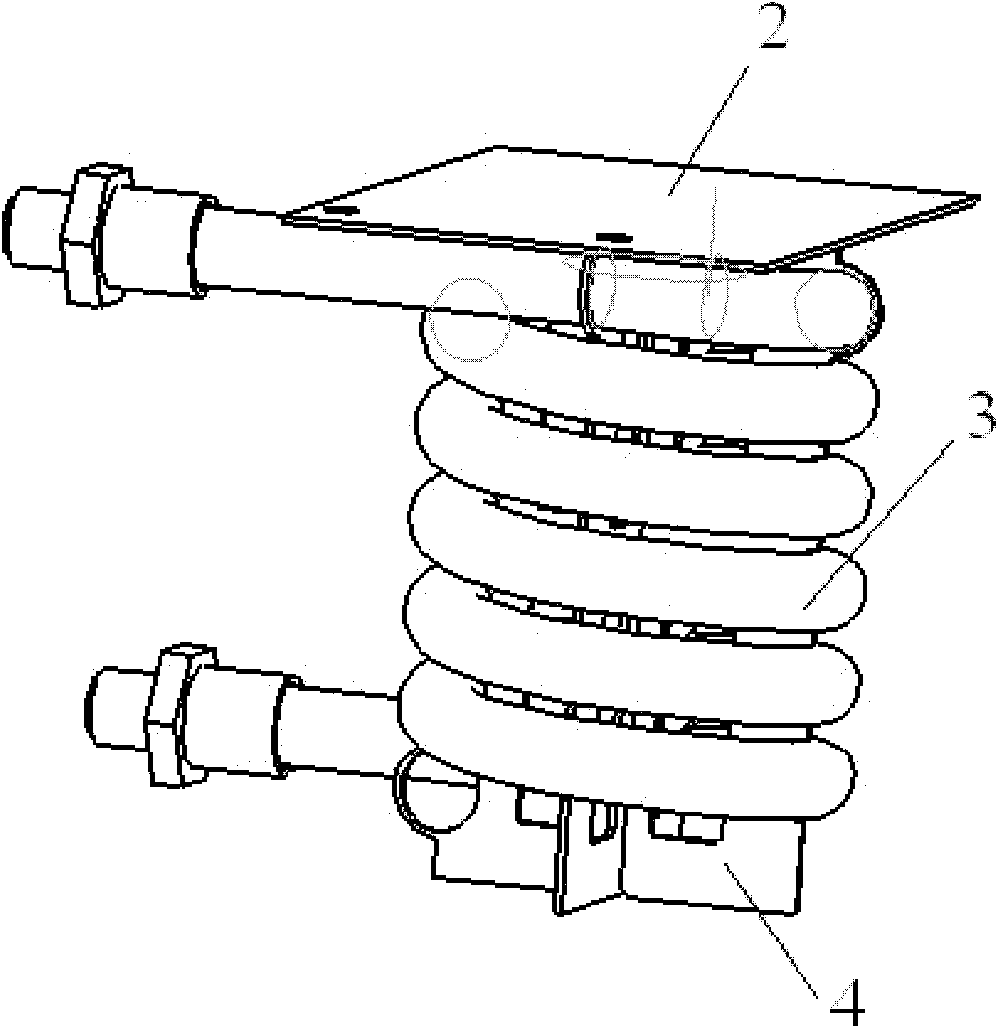

[0023] The structure of the stainless steel hose coil 3 is as follows figure 2 As shown, the stainless steel hose coil 3 is obtained by winding the whole stainless steel hose, the upper and lower ends of the stainless steel hose coil 3 are respectively connected to the cooling water inlet pipe and the cooling water outlet pipe through screws, and the coil fixing device 4 is a cross-shaped structure , pierced in the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com