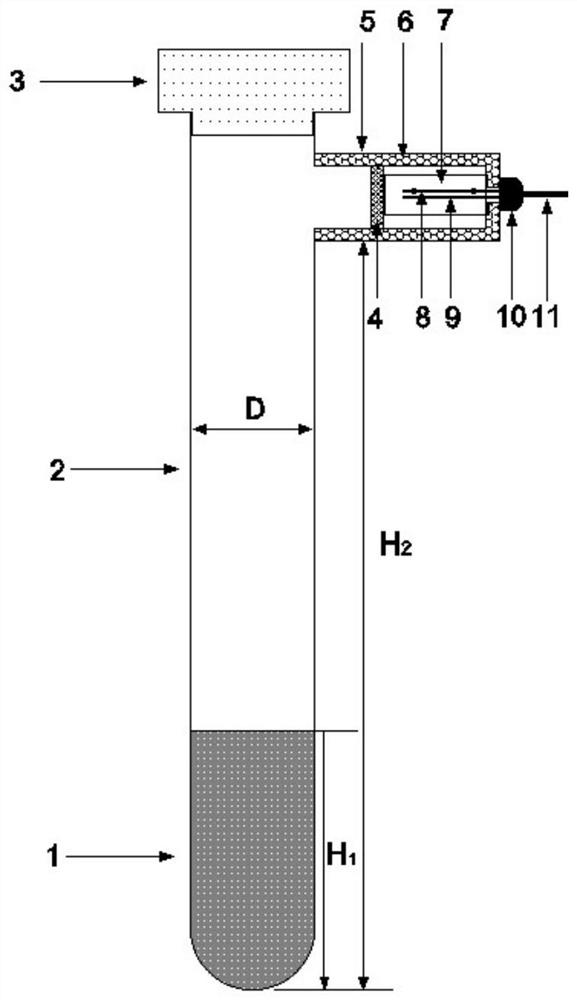

A fiber grating-based soil suction monitoring device and method

A matrix suction, fiber grating technology, applied in measurement devices, optical devices, soil material testing, etc., can solve the problems of inability to real-time monitoring, slow response speed, complicated operation, etc., to achieve good waterproof performance, fast response speed, and easy operation. simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

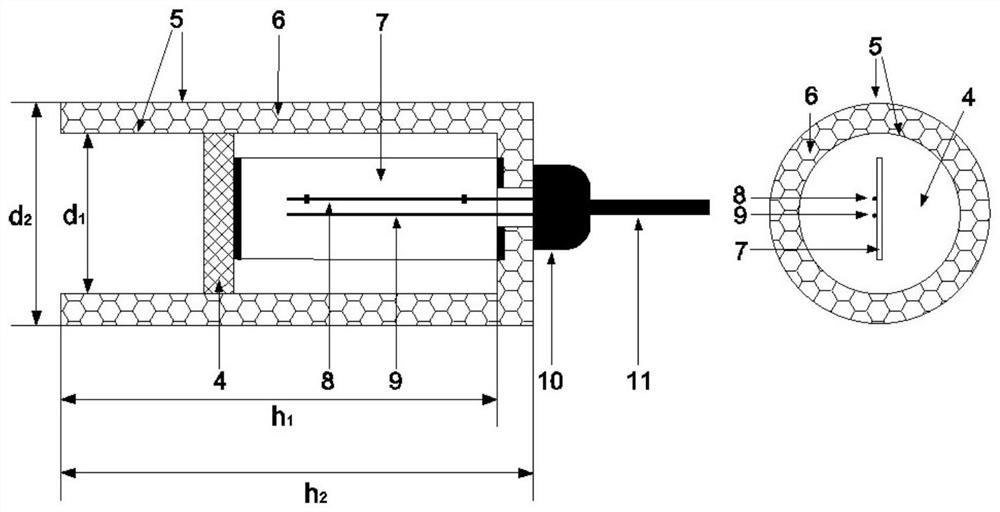

Method used

Image

Examples

Embodiment 1

[0071] The application of the device and method of the present invention requires the calibration experiment of soil matrix suction and FBG-1 strain value. The experiment is carried out under constant temperature indoors, and the soil type for calibration is clay. Specific steps are as follows:

[0072] Step 1: place the electronic soil tensiometer and the device of the present invention on the same layer of dried soil, and record the temperature T measured by FBG-2 as the calibration experiment temperature;

[0073] Step 2: When the matrix suction of the electronic soil tensiometer and the strain value ε of FBG-1 0 Record it when it reaches stability;

[0074] Step 3: Add water to make the soil saturated, and also record the matrix suction when it is stable and the strain value ε of FBG-1 b ;

[0075] Step 4: Under the action of water release and evaporation, continuously record several groups of stable matrix suction and FBG-1 strain value ε n (n=1, 2, 3...);

[0...

Embodiment 2

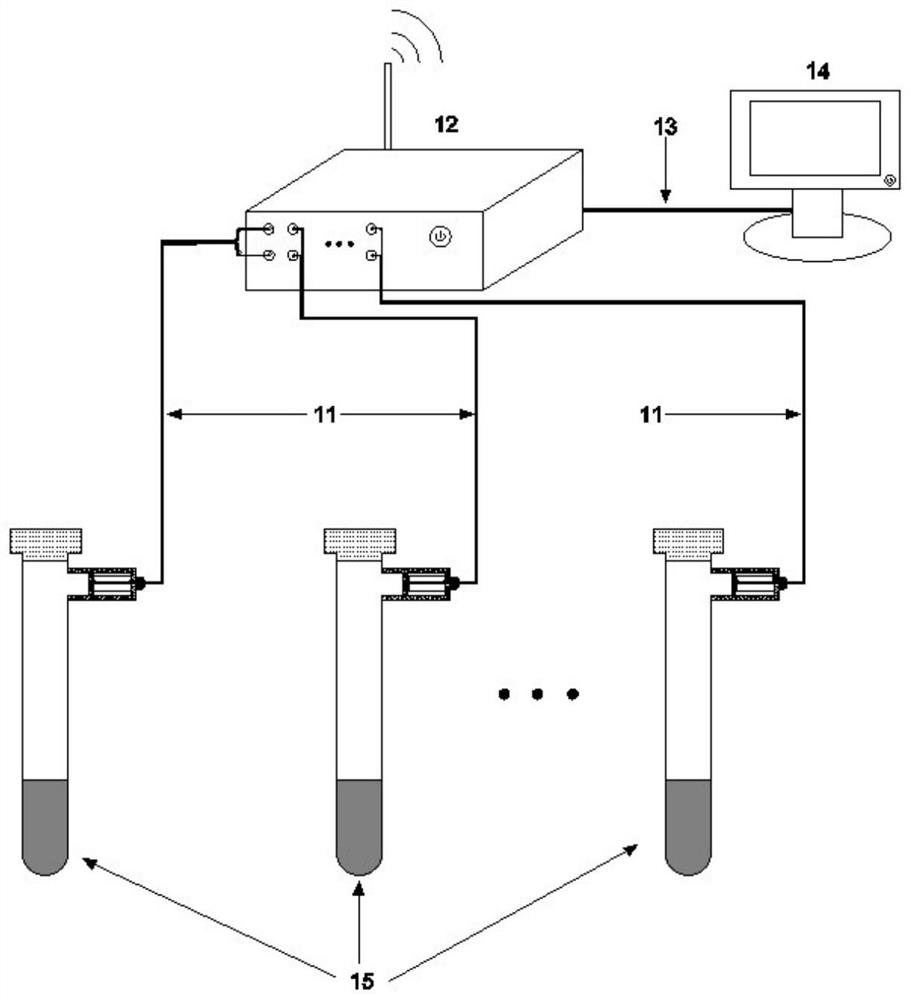

[0078] The field monitoring experiment of soil matrix suction is carried out by applying the method and device of the present invention. The experiment site is the back hill of Xianlin Campus of Nanjing University, and the soil type of the site is clay.

[0079]Step 1: Add an appropriate amount of water to the clay stick and make it upright, let the water soak the clay head, when you see water dripping from the surface of the clay head, it means that the clay head has reached saturation, then cover the rubber threaded cap, Make the inside of the clay rod airtight, and then bury the clay rod at a certain depth in the soil;

[0080] Step 2: Stand still for a period of time until the clay rod and the soil reach the water potential equilibrium, then turn on the fiber grating demodulator for monitoring;

[0081] Step 3: As the suction of the soil matrix changes, the displacement of the piston in the strain sensor will change, which will cause strain on the elastic steel sheet and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com