Hopper device for underground ore transfer cars

A technology of hopper device and ore transport vehicle, which is applied in the direction of inclined load-carrying vehicles, etc. It can solve the problems that hard ore is easy to scratch vehicle tires, aggravate road potholes and muddyness, and affect equipment transportation, etc., so as to improve operating efficiency, The structure is simple and the effect of increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

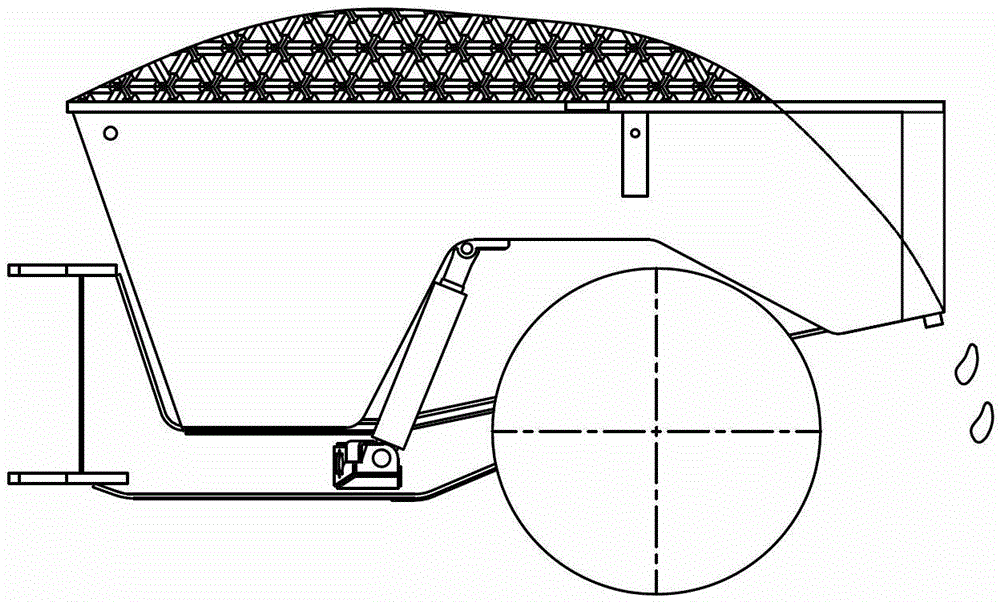

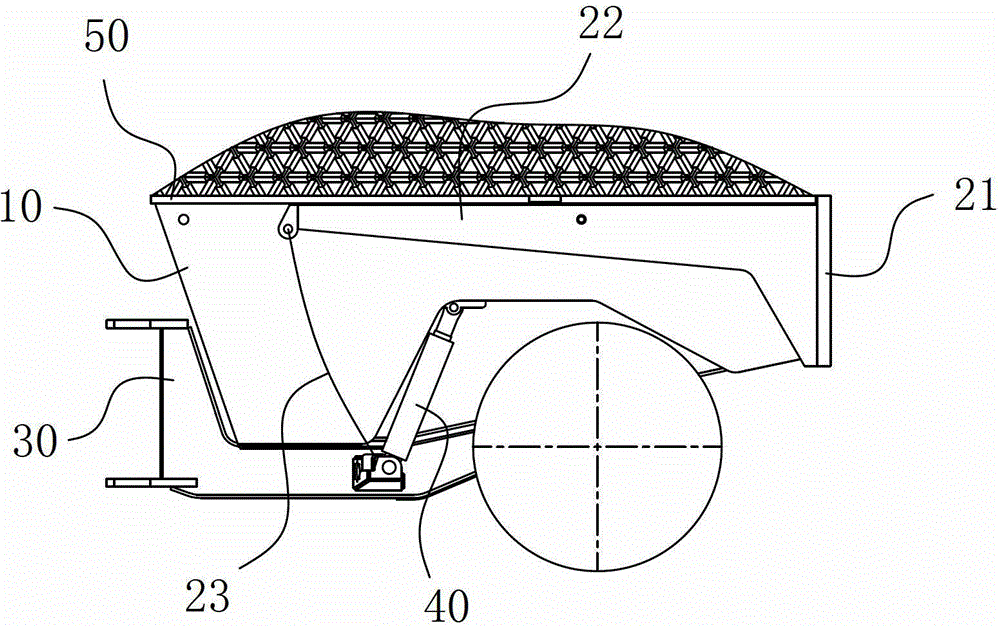

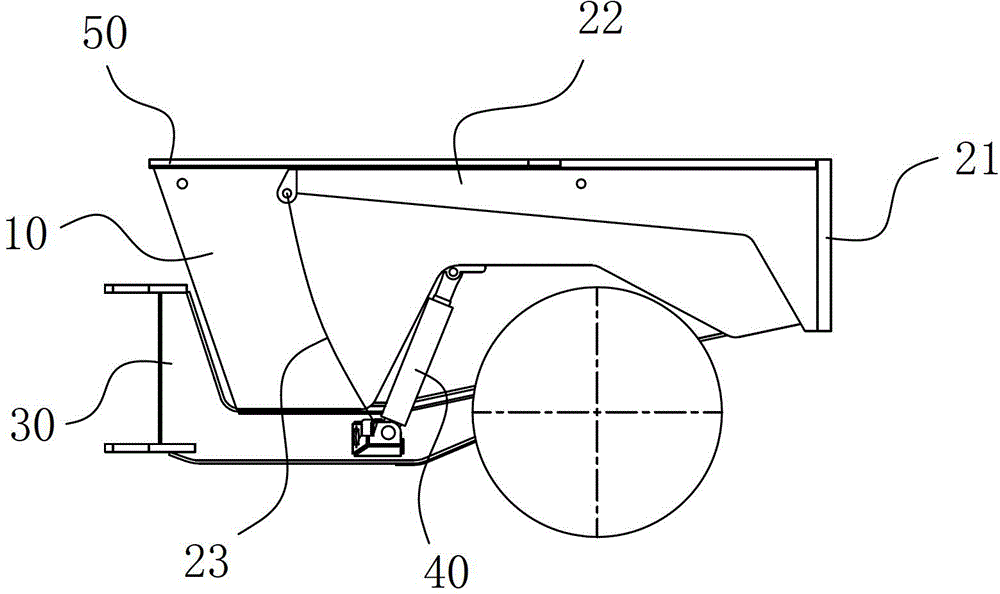

[0010] A hopper device for an underground ore-carrying vehicle, comprising a hopper 10 fixed on the rear of the car body and capable of pitching action thereon, the hopper device also includes a mine retaining unit, the mine retaining unit includes a The ore retaining plate 21 and the prolonging end 22 formed along at least one end of the ore retaining plate 21 to the front of the car body, the prolonging end 22 forms a hinged rotation fit with the outer wall of the hopper 10, and the prolonging end 22 and the car body are connected by a hinge The cable 23 is hinged, and the hinge point on the extension end 22 is located at a section from the hinge point on the extension end 22 to the top of the extension end 22. When the hopper 10 is in the initial state, the ore retaining plate 21 is wrapped around the mouth of the hopper, and the hopper 10 is in the initial state. When it is in the upward unloading state, the ore retaining plate 21 is affected by the hinge cable 23 and creat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com