Mechanical opening parallel mechanism with sector gate for quantitative loading of skip

A fan-shaped gate, mechanical technology, used in the field of opening parallel mechanisms, can solve the problems of increased hydraulic system control, large system, large impact force, etc., to achieve the effect of smooth opening and gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

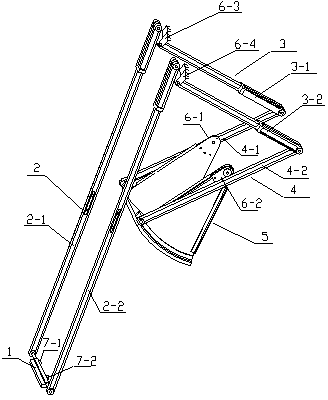

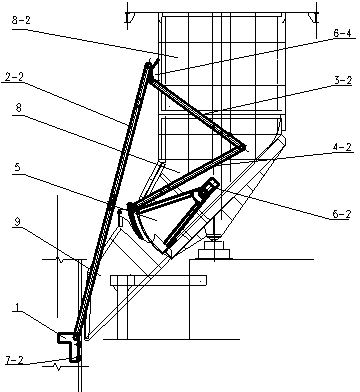

[0025] Such as figure 1 As shown, this embodiment includes a slider 1 , a transmission rod group 2 , an amplifying rod group 3 , an opening rod group 4 , a sector gate 5 , a bearing group 6 and a roller group 7 . The support group 6 includes a left support 6-1, a right support 6-2, a middle left support 6-3 and a middle right support 6-4.

[0026] The transfer rod set 2 includes a left transfer link 2-1 and a right transfer link 2-2. The above-mentioned left transfer link 2-1 and right transfer link 2-2 are distributed on the left and right sides of the slider 1, and one ends of the two transfer links are hingedly connected to the slider 1 respectively. image 3 One configuration of the transfer link is shown.

[0027] The amplifying rod group 3 includes a left amplifying connecting rod 3-1 and a right amplifying connecting rod 3-2. One end of the left amplifying link 3-1 is hinged on the middle left support 6-3, and the other end of the left transmission link 2-1 is also h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com