Non-antimony flame-retardant polyamide composite material and preparation method and application thereof

A flame-retardant polyamide and composite material technology, which is applied in the field of modified polymer new materials, can solve the problems of easy flow marks and low CTI value, and achieve the effect of reducing production costs and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

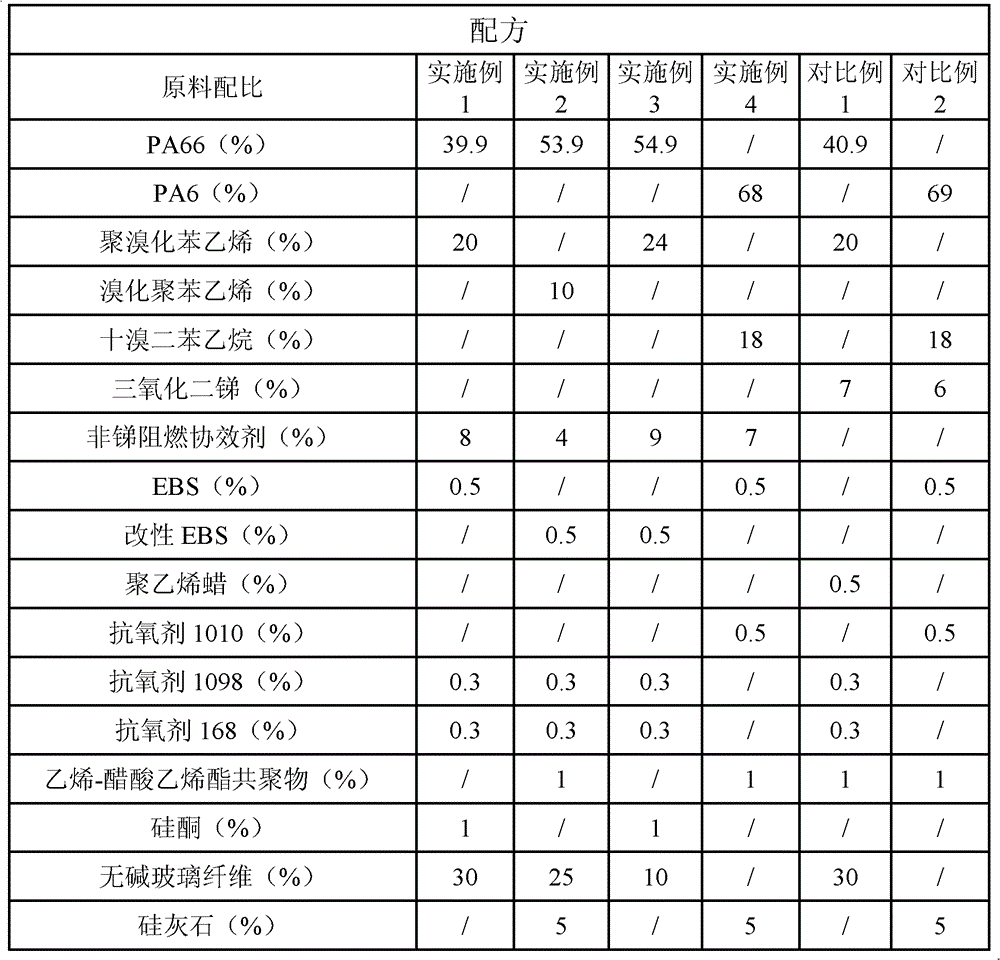

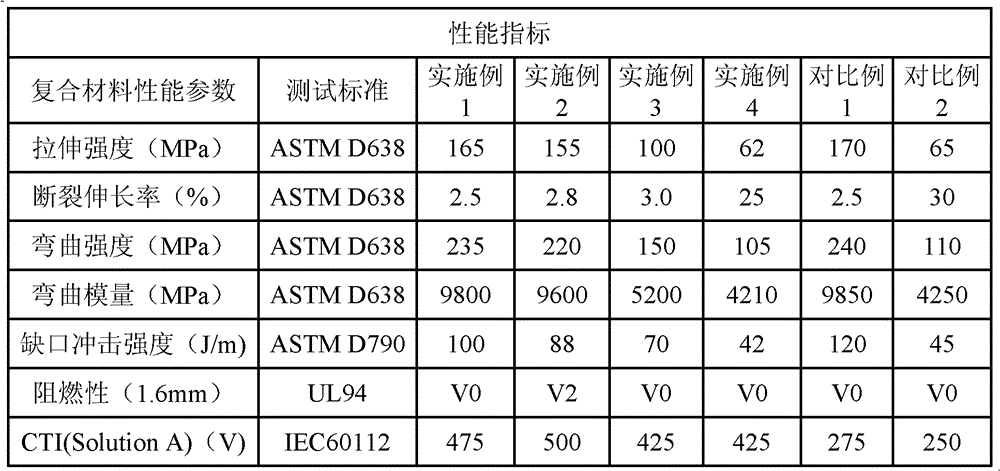

[0036] The raw material formula of the non-antimony flame-retardant polyamide composite material and the performance parameters of the obtained composite material are shown in Table 1.

[0037] The preparation method of the non-antimony flame-retardant polyamide composite material is as follows: add all other components in the formula in Table 1 except PA66 and reinforcing modifier (alkali-free glass fiber and wollastonite) to a high-speed mixer and mix uniformly to obtain a mixture ,take out. Add PA66 from the main feeding port of the twin-screw extruder, add the mixture at the first side feeding port, and then add the reinforcement modifier at the second side feeding port, so that all the materials in the twin-screw extruder Mix evenly, extrude, cool, and pelletize to obtain non-antimony flame-retardant polyamide composite material.

[0038] The extrusion temperatures of Examples 1-3 from the feed section to the die are: 240°C, 275°C, 280°C, 275°C, 270°C, 265°C, 265°C and 2...

Embodiment 4

[0043] The raw material formula of the non-antimony flame-retardant polyamide composite material and the performance parameters of the obtained composite material are shown in Table 1.

[0044] The preparation method of the non-antimony flame-retardant polyamide composite material is as follows: add all other components in the formula in Table 1 except PA6 and reinforcing modifier (wollastonite) to a high-speed mixer and mix uniformly to obtain a mixture, and take it out. Add PA6 from the main feeding port of the twin-screw extruder, add the mixture at the first side feeding port, and then add the reinforcement modifier at the second side feeding port, so that all materials are in the twin-screw extruder Mix evenly, extrude, cool, and pelletize to obtain non-antimony flame-retardant polyamide composite material.

[0045] The extrusion temperature of Example 4 from the feed section to the die is respectively: 210°C, 230°C, 245°C, 245°C, 240°C, 235°C, 230°C and 230°C, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com