Construction Treatment Method of Cast-in-situ Triangular Composite Foundation Pile

A treatment method, triangular technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of large engineering volume, pollution of the surrounding environment, and on-site environmental pollution, so as to reduce construction costs, avoid pollution, and reduce construction The effect of unearthed volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technology of the present invention will be described in further detail below in conjunction with accompanying drawing and specific implementation:

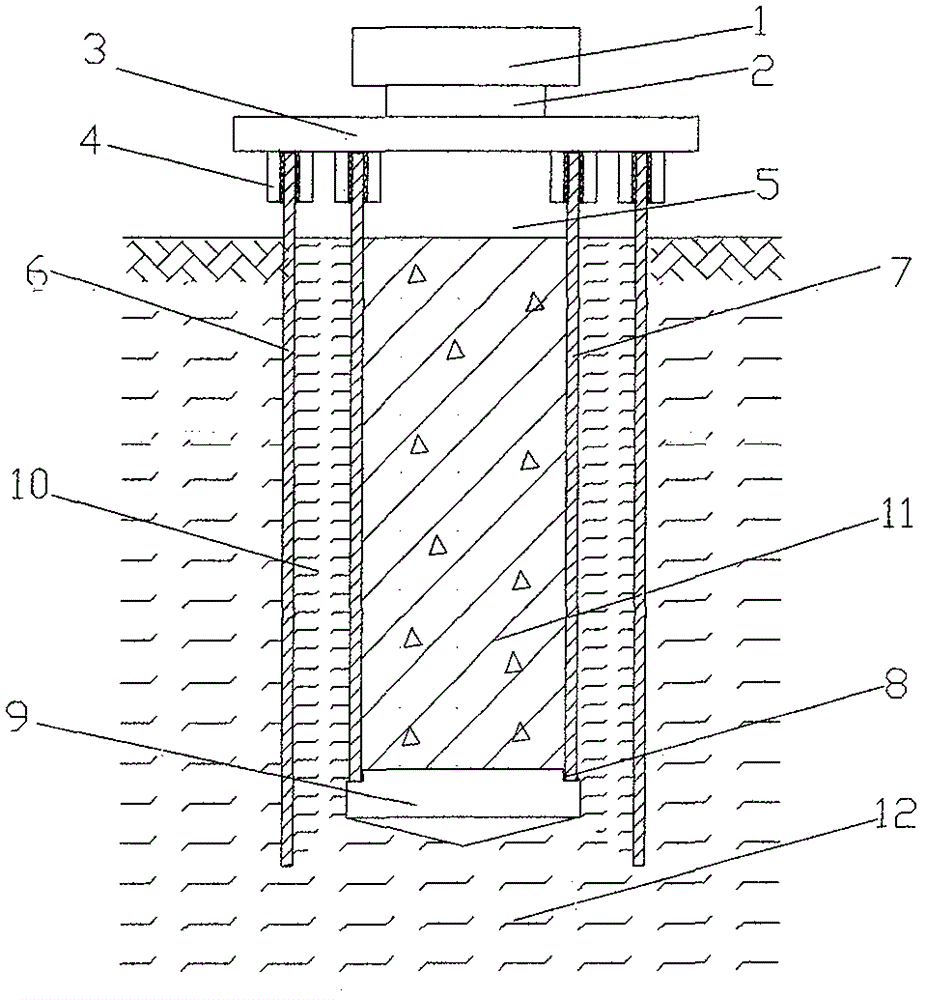

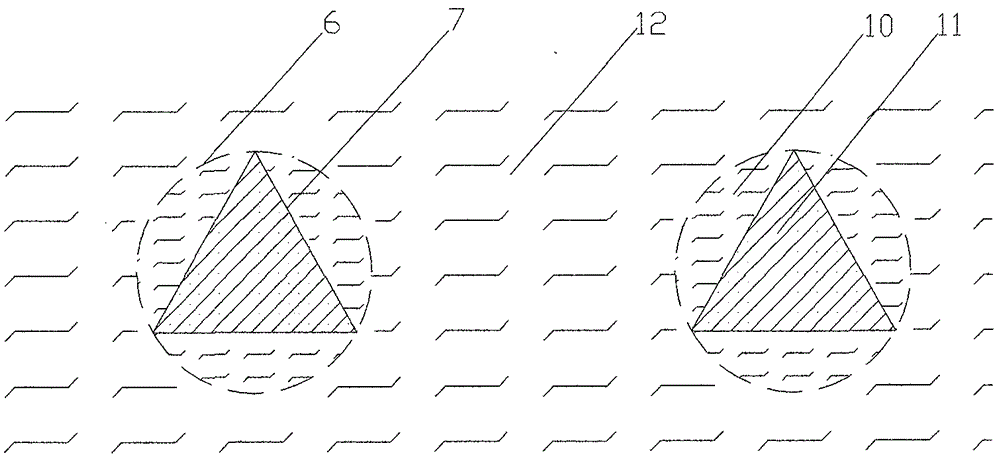

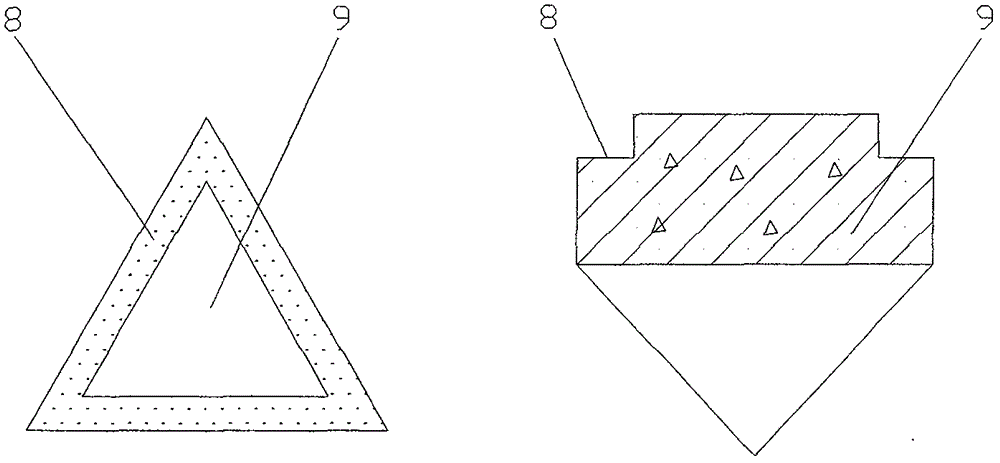

[0023] One, as attached figure 1 , 2 , 3, 4, the construction treatment method of this patent provides a kind of vibration hammer with medium and high frequency hydraulic or electric 1 , flange 2 , special fixture chute beam 3 , mobile telescopic chuck 4 The combination of equipment, while the circular outer steel casing 6 and triangular inner steel casing 7 The upper part is clamped so that the triangular inner steel casing 7 The bottom end is embedded in the triangular reinforced concrete solid pile tip 9 upper outer groove 8 , start the medium and high frequency hydraulic or electric vibratory hammer 1 Implement vibration pressure to make the circular outer steel casing 6 , Triangular inner steel casing 7 and triangular reinforced concrete solid pile tips 9 The combination is quickly and simultaneously v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com