Well logging densimeter

A measuring tube and detector technology, applied in the field of measuring instruments, can solve the problems of difficult maintenance, inaccurate measurement, inconvenient use, etc., and achieve the effect of solving difficult maintenance, good repeatability and linearity, and solving inconvenience in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

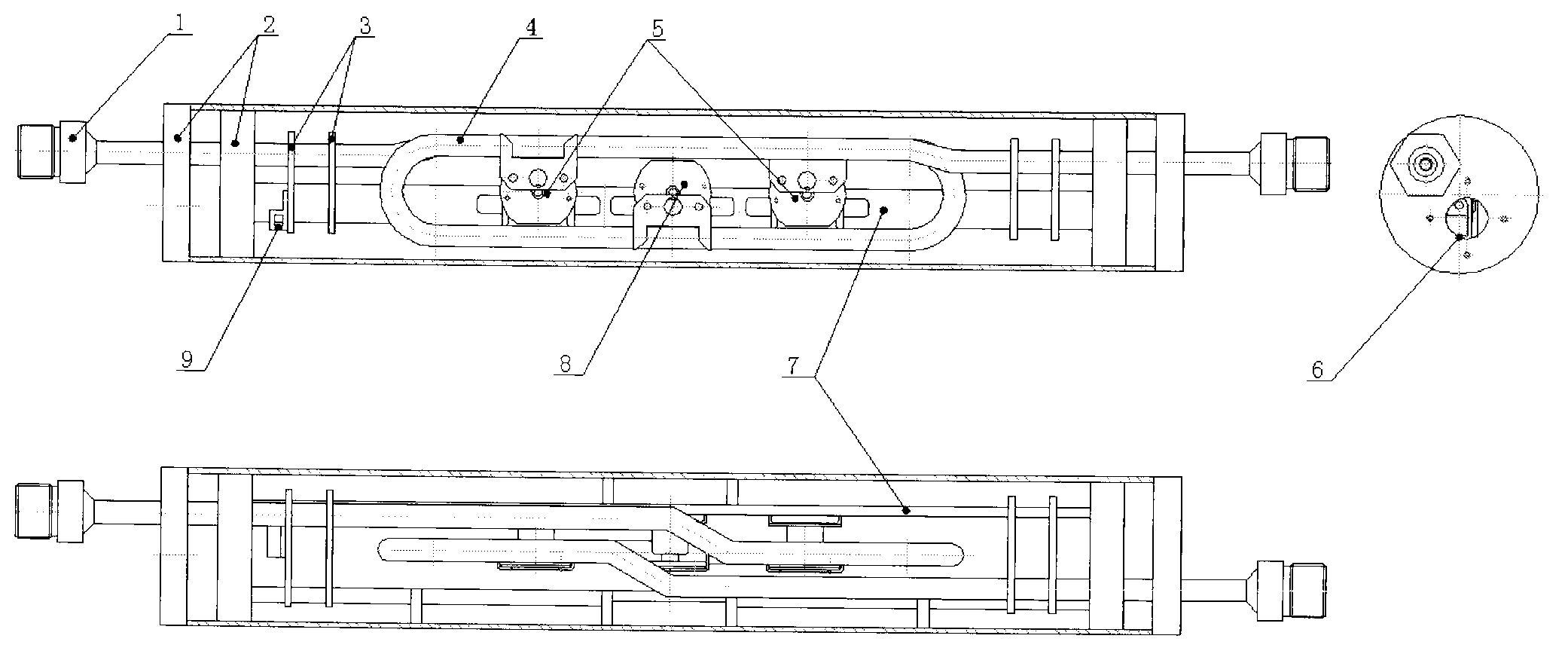

Embodiment 1

[0024] In order to ensure that the primary table can work normally in the harsh environment of the underground, the measuring tube 4 must be cold-formed with a seamless tube, and intermittent welding is not allowed in the middle, and it must be ensured that the measuring tube 4 cannot be bent, welded, etc. during the assembly process. Damaged during processing. The assembly and welding of the primary meter should ensure small deformation, ensure that the measuring tube can vibrate freely under normal environment and high temperature and high pressure, and can not scratch any fixed parts.

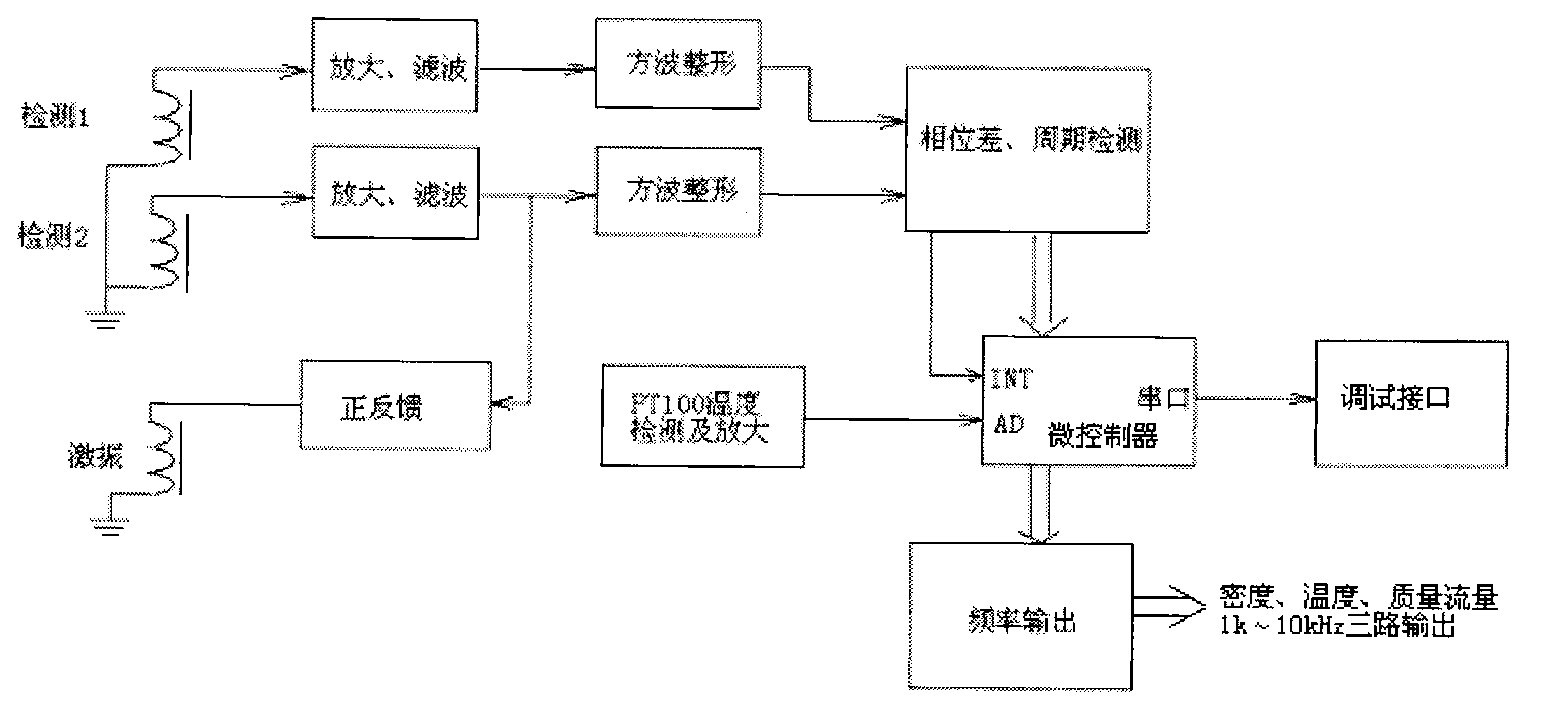

[0025] In order to ensure that the secondary meter can work normally in the harsh environment of the underground, all electronic components are selected from the highest temperature grade devices, and have been energized and aged at a temperature of 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com