Embedded touch display and manufacturing method thereof

A technology for a touch display and a manufacturing method, which is applied in the fields of instruments, optics, electrical and digital data processing, etc., can solve the problems of reducing the width of the black matrix, color mixing, light leakage, etc., and achieve the effect of improving the light leakage or color mixing problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

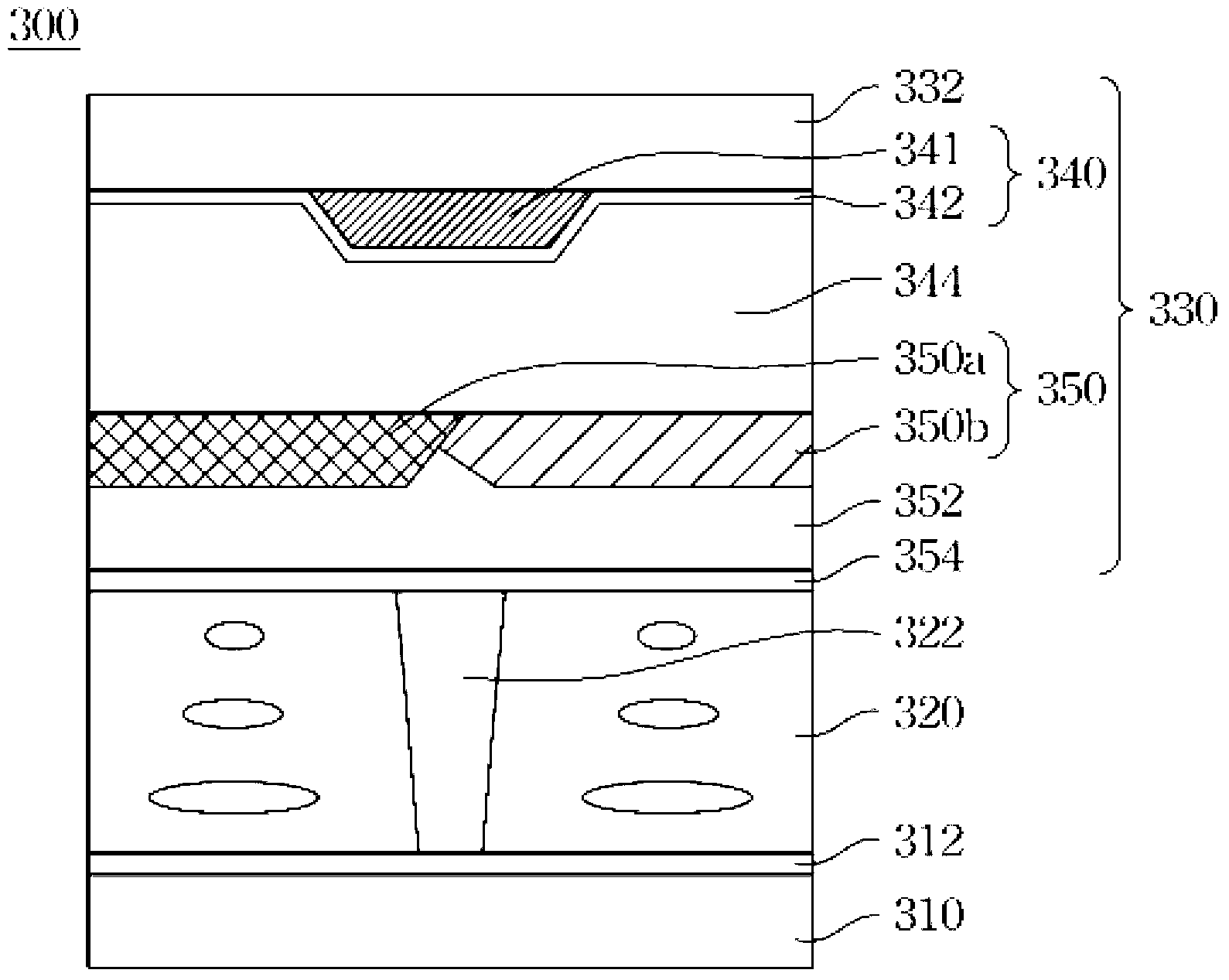

[0054] According to another embodiment of the present invention, the manufacturing method includes an in-cell touch display.

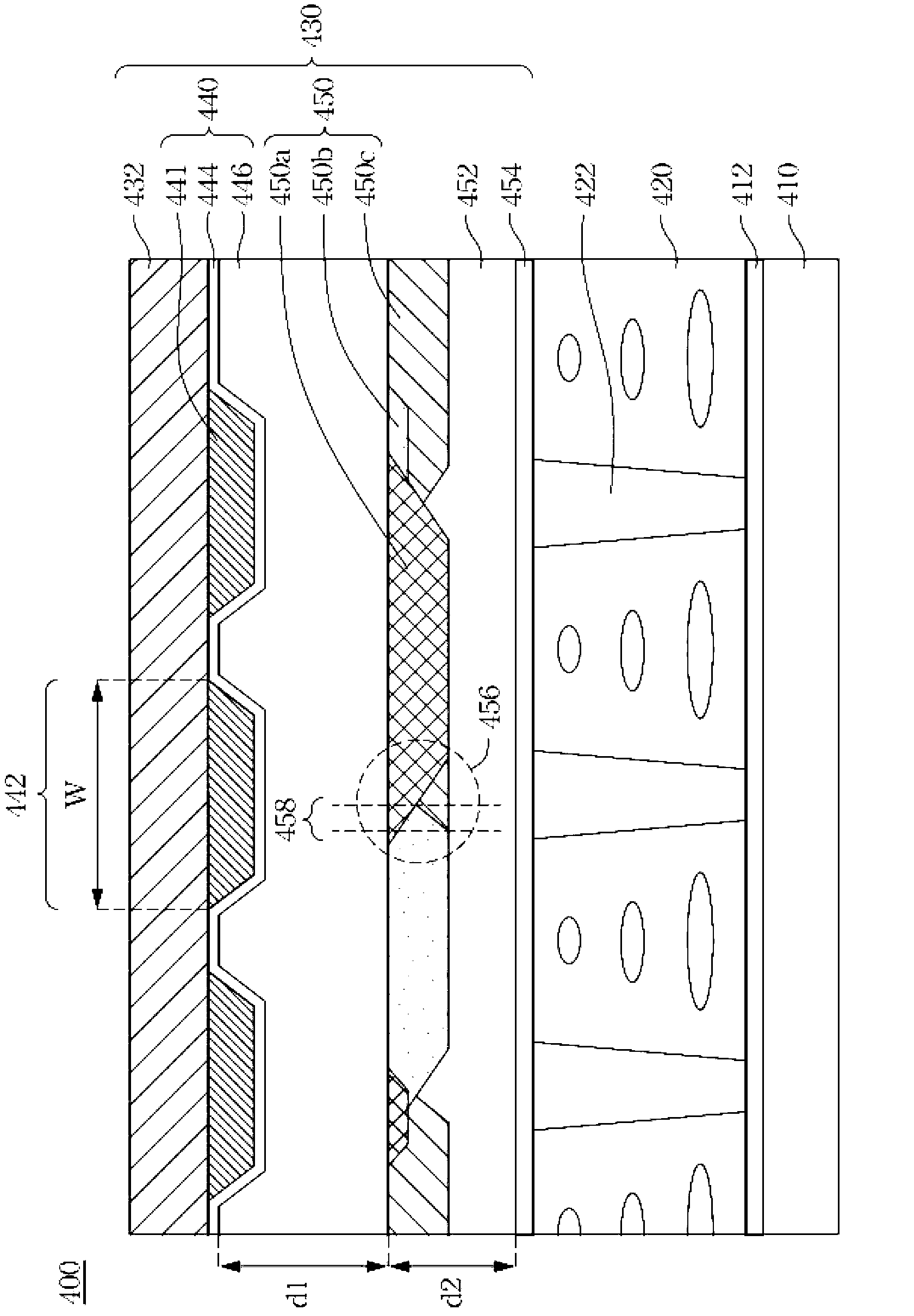

[0055] Also refer to Figure 2A , providing a thin film transistor array substrate 410, with a first transparent electrode 412 located on the thin film transistor array substrate 410;

[0056] A color filter array pattern substrate 430 is also provided, including: providing a substrate 432 with a plurality of black matrices 440 forming a plurality of first light-shielding regions 442; providing a second transparent electrode 444 covering the black matrix and the On the substrate 432; provide a first overcoat layer covering 446 above the second transparent electrode 444, wherein the black matrix, the second transparent electrode 444 and the first overcoat layer 446 form a touch sensor component layer 440; then, a color filter pattern layer 450 is provided on the first overcoat layer 446, the color filter pattern layer 450 is composed of a plurality of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com