Signal cable stripping pliers

A signal cable and stripping pliers technology, applied in the field of signal cable stripping pliers, can solve problems such as the influence of signal cable characteristics, unsafe construction process, injury to workers, etc., to increase safety factor, facilitate stripping, and reduce resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

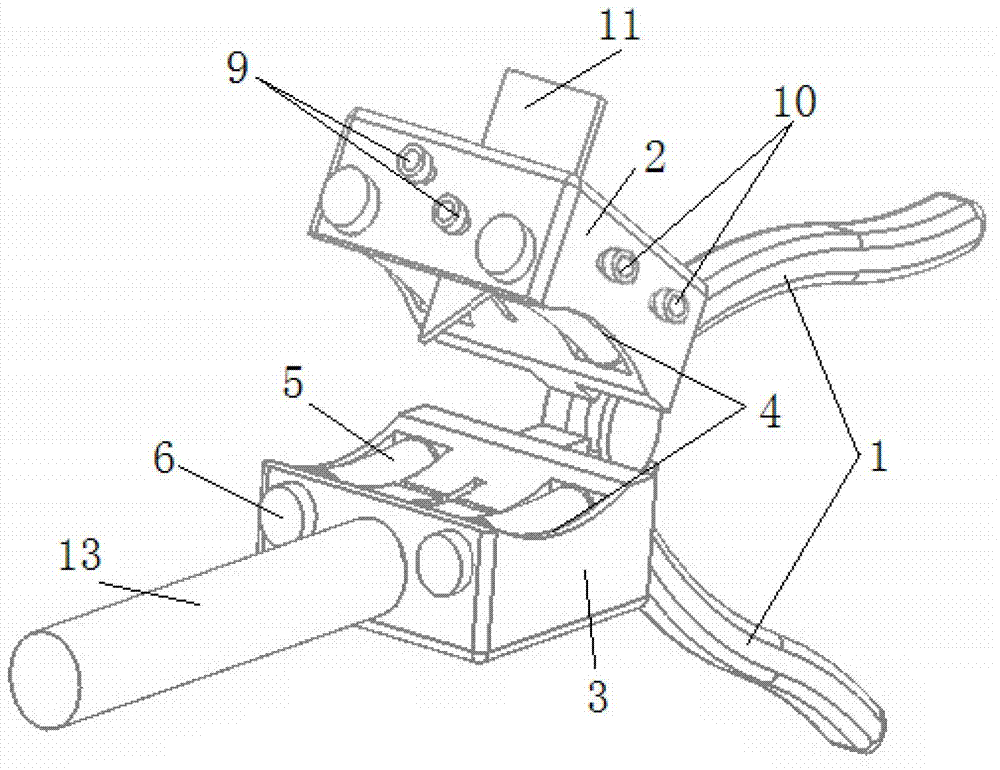

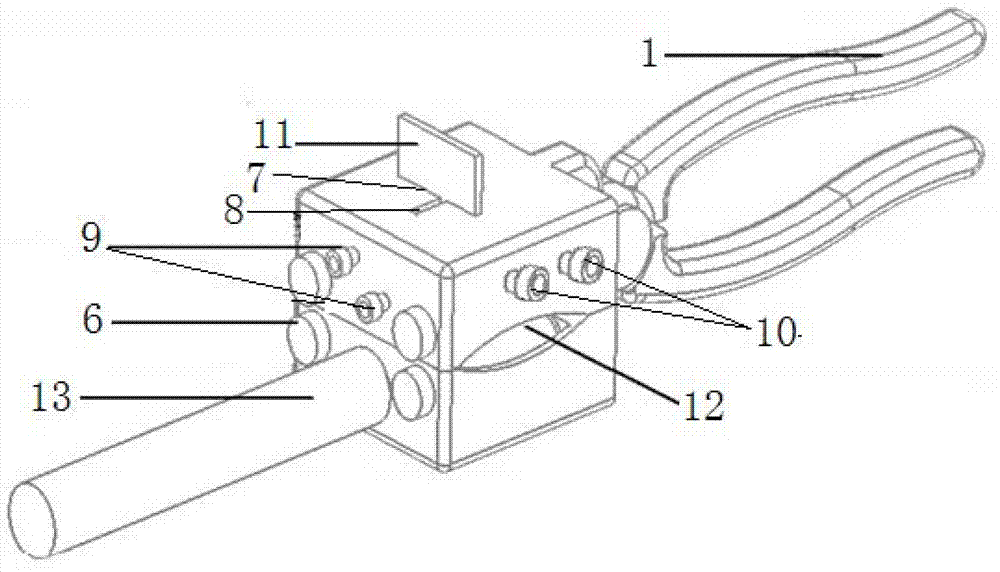

[0023] A signal cable stripping pliers, including two handles 1, upper jaw 2, lower jaw 3, the lower surface of the upper jaw 2, the upper surface of the lower jaw 3 are respectively provided with a The groove 4 of the axis of symmetry, the two grooves 4 cooperate with each other as the cable slideway 12, the two ends of the groove 4 of the upper jaw 2 and the lower jaw 3 are respectively horizontally provided with a roller 5, and the four rollers 5 are respectively On the set bolt 6, four bolts 6 are screwed into the upper jaw 2 and the lower jaw 3 respectively in pairs from the front ends of the upper jaw 2 and the lower jaw 3, and there are two bolts on the upper jaw 2 from top to bottom. The slits running through the upper surface of the upper jaw are respectively slit 1 7 and sieve 2 8, sieve 1 7 is perpendicular to the roller 5, sieve 2 8 is parallel to the roller 5, sieve 1 7, sipe 2 8 The front end of the upper jaw 2 is screwed into a group of adjusting bolts 9 perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com