Vacuum cleaner filter bag having a side fold

A technology of vacuum cleaners and filter bags, which can be used in cleaning equipment, cleaning devices, specific bag/box production, etc., and can solve the problems of complex non-woven square bottom bag production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

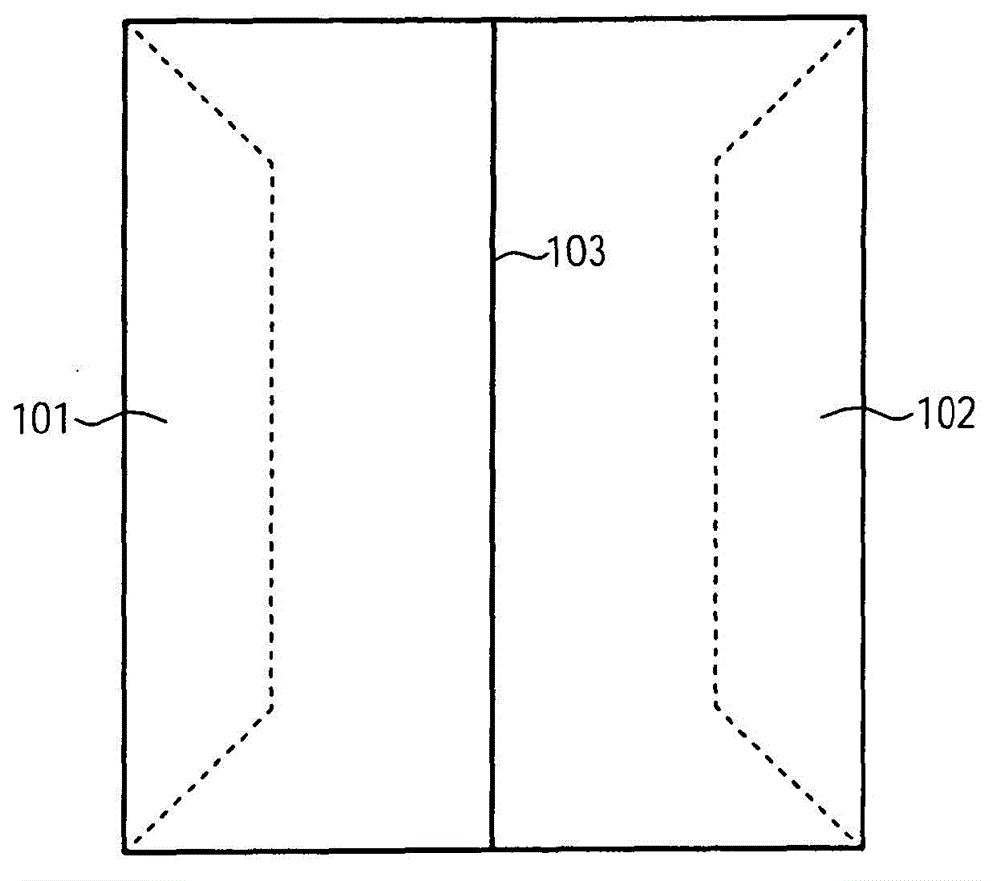

[0068] figure 1 A plan view of an exemplary vacuum cleaner filter bag is schematically shown. The exemplary vacuum cleaner filter bag has a rectangular design and comprises two side folds 101 and 102 each formed by two folded legs. The two side folds are shown here in the folded-in or folded-in state. In this state, the vacuum cleaner filter bag can easily be inserted into the vacuum cleaner. Additionally, this condition allows for a small package size and allows for easy deployment of the vacuum cleaner filter bag while the vacuum cleaner is in operation.

[0069] When inserting the vacuum cleaner filter bag into the vacuum cleaner and exposing the vacuum cleaner filter bag to the air flow to be cleaned in the vacuum cleaner, it is possible in particular to pass through the vacuum cleaner filter bag in the vacuum cleaner housing. The pressure difference between the inside and outside causes the side folded parts 101 and 102 to turn to the outside accordingly, thereby incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com