Polyurethane resin

一种聚氨酯树脂、氨基甲酸酯的技术,应用在聚氨酯树脂领域,能够解决成本高、制造工序复杂、低模量等问题,达到简单制造、廉价且制造、优异胶粘性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

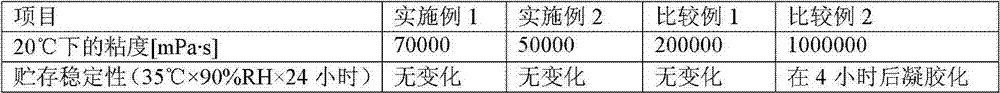

Embodiment 1

[0076] 458 g of polyoxypropylene monoalcohol (manufactured by Asahi Glass Co., Ltd. PML-S-1005) with a number average molecular weight of 5000, 462 g of polyoxypropylene diol with a number average molecular weight of 13000 (manufactured by Asahi Glass Urethane Co., Ltd. PML-4013), isophorone 53 g of diisocyanate (Desmodur I manufactured by Sumika Bayer) were mixed. This mixture was reacted at 90° C. for 24 hours to obtain a polyurethane prepolymer.

[0077] 21 g of aminoethylaminopropylmethyldimethoxysilane (KBM-602 manufactured by Shin-Etsu Chemical Co., Ltd.) was added to 515 g of this prepolymer, and stirred at 30° C. for 30 minutes. Then, 7.3 g of aminopropylmethyldimethoxysilane (KBM-902 manufactured by Shin-Etsu Chemical Co., Ltd.) and 0.3 g of methanol were put into the prepolymer, and stirred at 30° C. for 30 minutes to obtain a polyurethane resin. .

Embodiment 2

[0079]458 g of polyoxypropylene monoalcohol (manufactured by Asahi Glass Co., Ltd. PML-S-1005) with a number average molecular weight of 5000, 462 g of polyoxypropylene diol with a number average molecular weight of 13000 (manufactured by Asahi Glass Urethane Co., Ltd. PML-4013), isophorone 53 g of diisocyanate (Desmodur I manufactured by Sumika Bayer) were mixed. This mixture was reacted at 90° C. for 24 hours to obtain a polyurethane prepolymer.

[0080] 21 g of aminoethylaminopropylmethyltrimethoxysilane (KBM-603 manufactured by Shin-Etsu Chemical Co., Ltd.) was added to 515 g of this prepolymer, and stirred at 30° C. for 30 minutes. Then, 7.3 g of aminopropylmethyldimethoxysilane (KBM-902 manufactured by Shin-Etsu Chemical Co., Ltd.) and 0.3 g of methanol were put into the prepolymer, and stirred at 30° C. for 30 minutes to obtain a polyurethane resin. .

Embodiment 3 and 4、 and comparative example 3

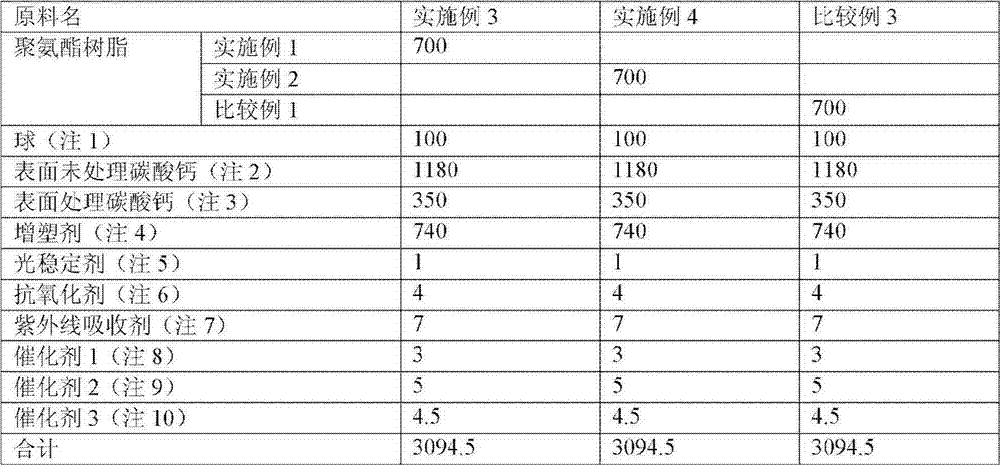

[0089] Base

[0090] The ingredients with the weights shown in Table 1 were put into a mixing mixer equipped with a heating and pressure reducing device, and stirred for 30 minutes. Then, the mixture was mixed and stirred at 60° C. for 30 minutes, and then stirred and mixed for 20 minutes under reduced vacuum to obtain a base.

[0091] Hardener

[0092] The curing catalyst and calcium carbonate of the weight shown in Table 1 were mixed at room temperature, and mixed and stirred for 10 minutes to obtain a curing agent.

[0093] The base prepared as described above was mixed with a curing agent at a ratio of 100:10 (weight ratio) to obtain a curable composition.

[0094] [Table 1]

[0095]

[0096] Unit: [g]

[0097] (Note 1) Manufactured by Matsumoto Yushi Co., Ltd., average particle size 60 μm, Tg 140°C

[0098] (Note 2) Ground calcium carbonate, "WHITON SB" manufactured by Shiraishi Calcium Co., Ltd., average particle size 3.7 μm

[0099] (Note 3) "Calfine 500" manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com