Working unit for processing of wooden boards and the like

An operating unit, panel technology, used in woodworking appliances, manufacturing tools, special forming/shaping machines, etc., which can solve the problems of reducing the output and versatility of known turning components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

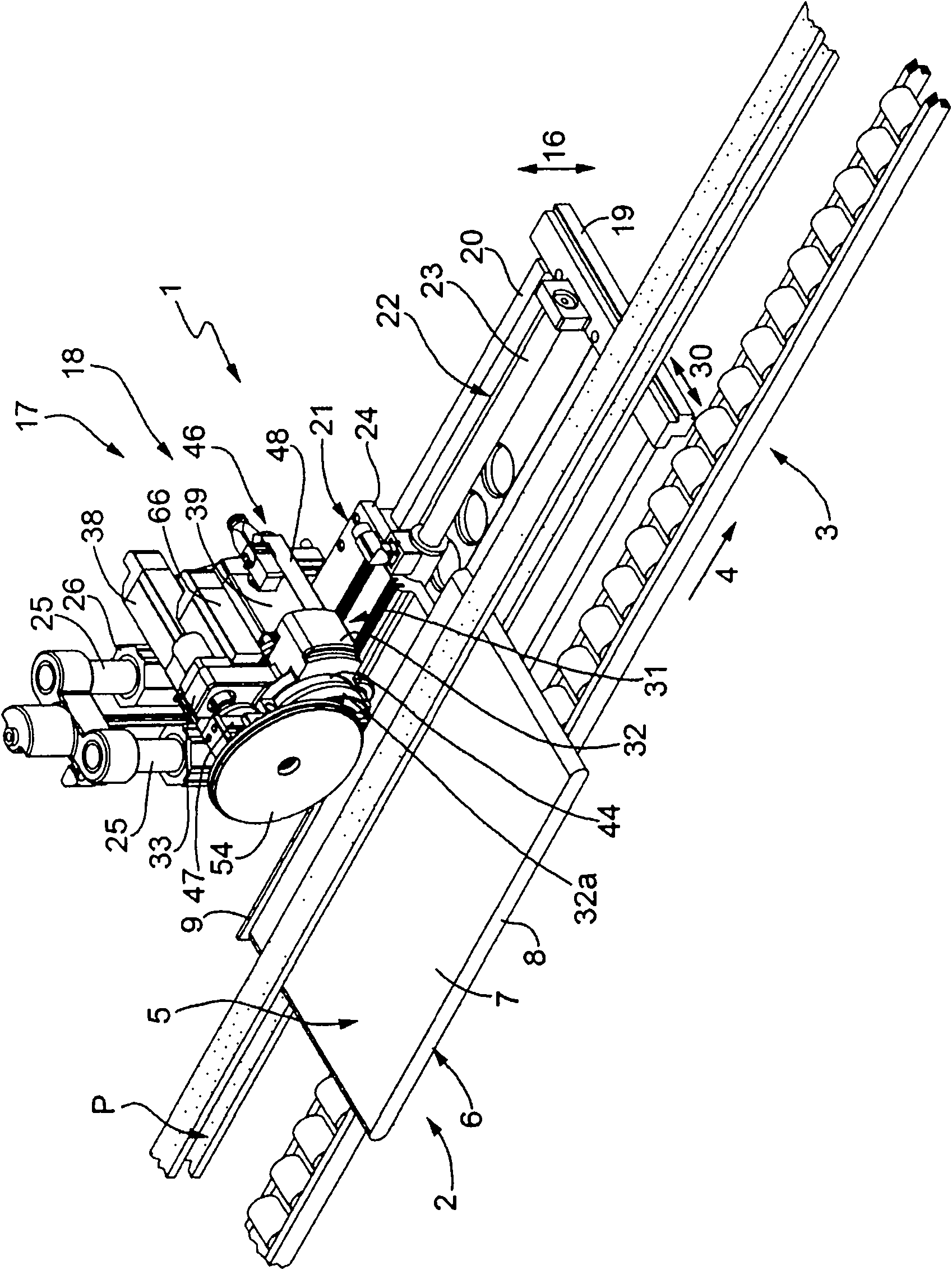

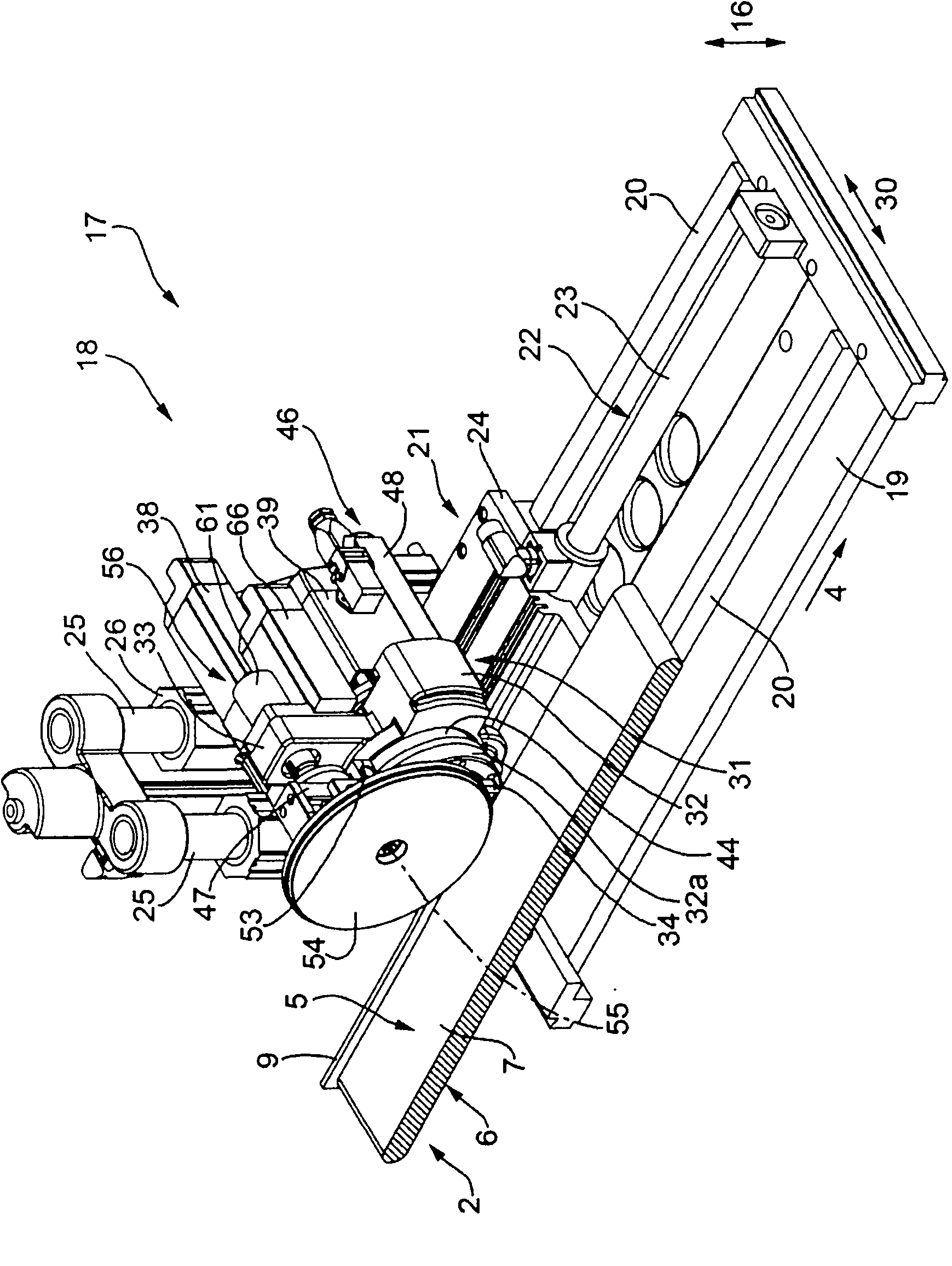

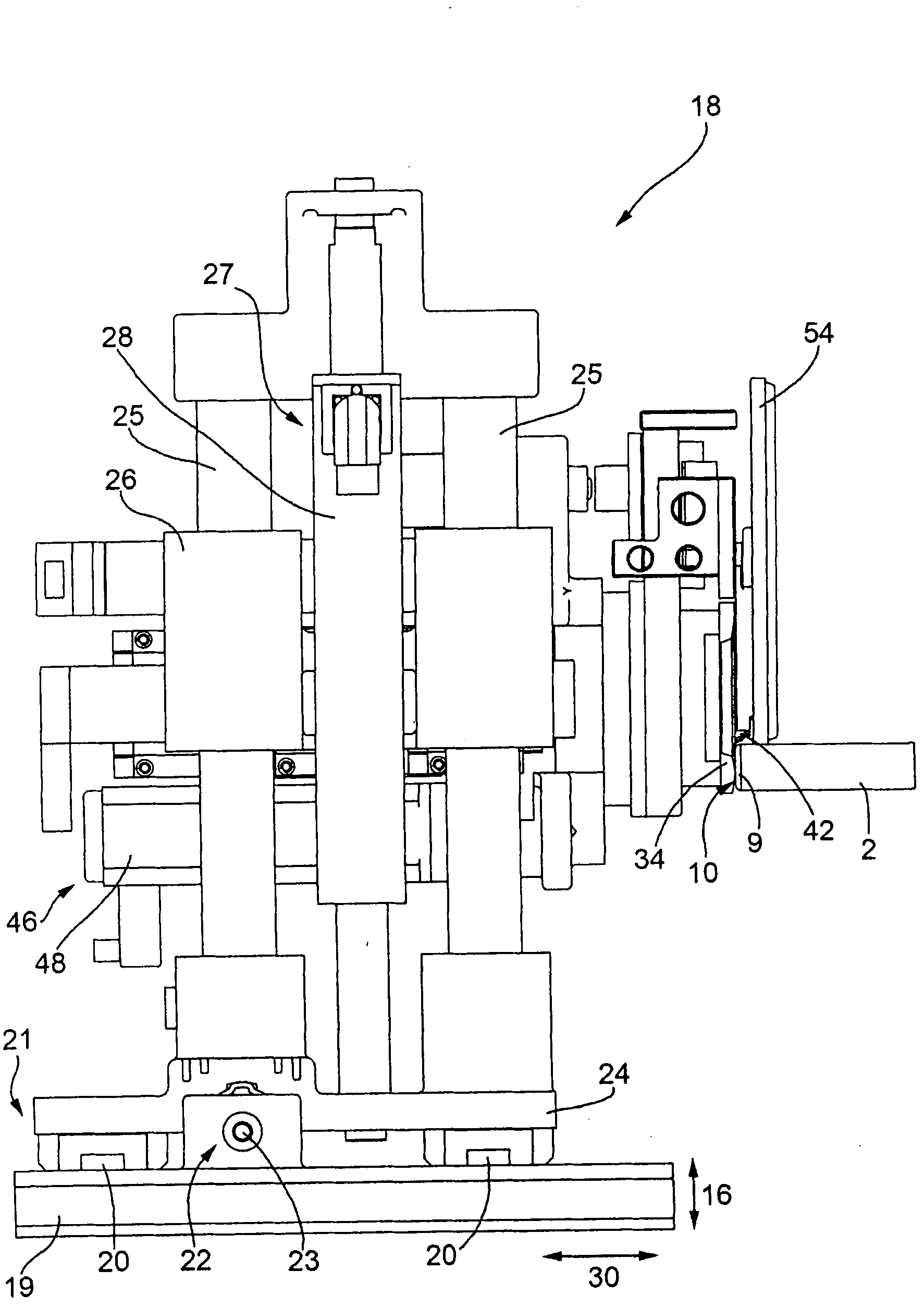

[0016] figure 1 The number 1 in indicates the whole of a trimming and edger machine for trimming a wooden panel 2 or the like, comprising a device for continuously feeding said panel 2 along a support surface P and in a substantially horizontal direction 4 Known delivery device 3 .

[0017] Each of said panels 2 lies "flat" on a surface P, said panels 2 being substantially parallelepiped-shaped with a generally rectangular cross-section and a longitudinal section with rounded ends, the panels 2 being parallel to each other and defining said A substantially planar top face 5 and a substantially planar bottom face 6 of a part of the annular profile 7 of the panel 2 are bounded by two substantially perpendicular faces 8 parallel to each other and to the direction 4 in the example shown. The sides define the border.

[0018] Said panel 2 is continuously fed by means 3 in direction 4 through a trimming station (not shown), where at least one face 8 is fitted with a substantially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com