Structure for connecting steel pipe sheet piles, and steel pipe sheet pile structure

A structure and sheet pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as unstable quality, achieve simple structure, prevent water pollution, and excellent connection operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

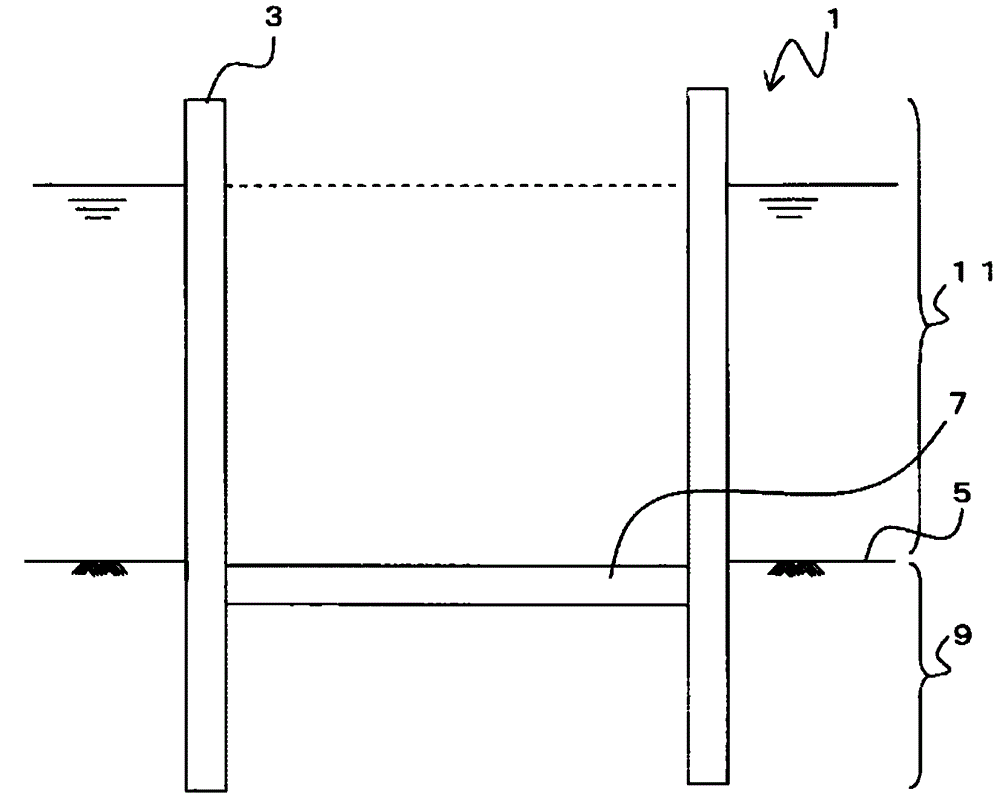

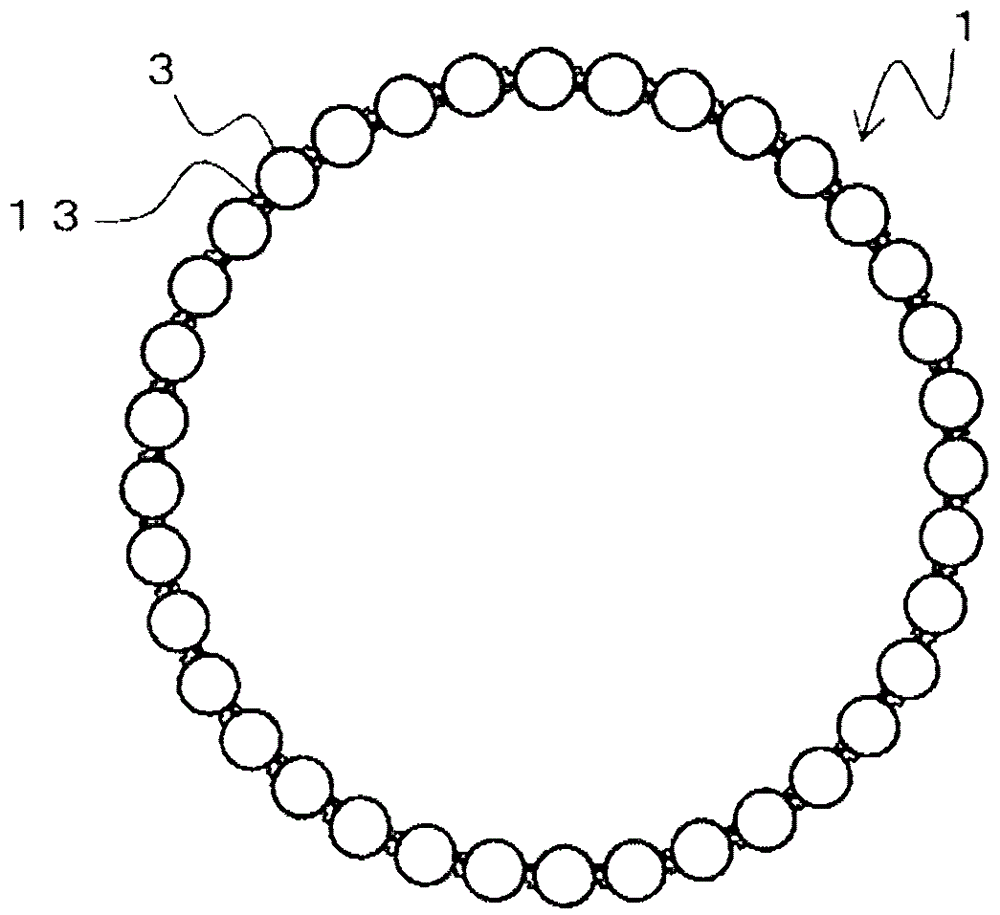

[0049] Hereinafter, structures according to embodiments of the present invention will be described. Figure 1A , Figure 1B A structure 1 showing one embodiment of the present invention is shown. Figure 1A is the elevation of structure 1, Figure 1B is a plan view of the structure 1 .

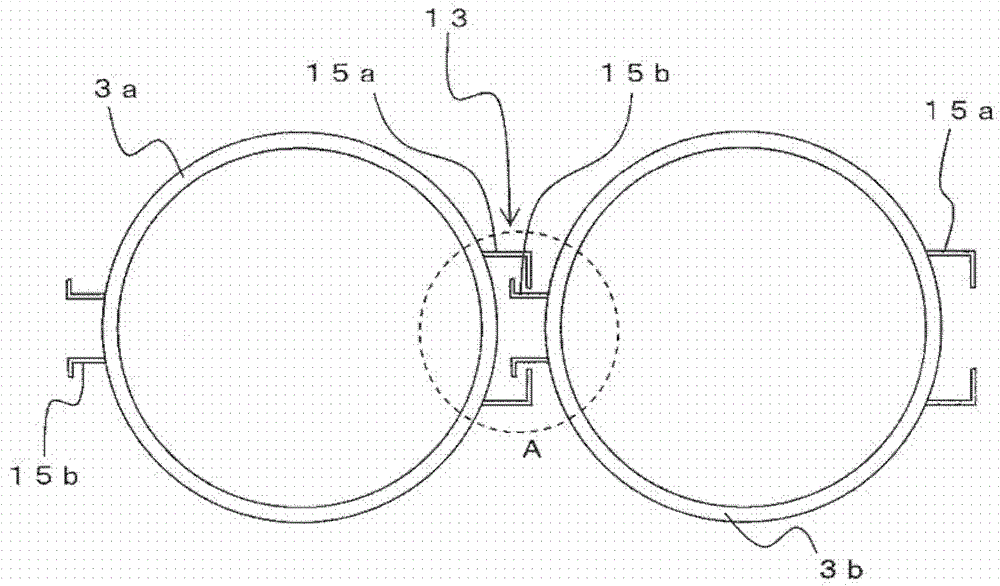

[0050] The structure 1 mainly includes a plurality of steel pipe sheet piles 3 installed on the water bottom 5, a bottom plate 7, and the like. The steel pipe sheet pile 3 constituting the structure 1, for example Figure 1B A plurality of them are arranged circularly as shown. Joining of the steel pipe sheet piles 3 is performed by the joint 13 provided in the steel pipe sheet pile 3 side. Since the joint 13 has watertightness, water in the range surrounded by the plurality of steel pipe sheet piles 3 can be discharged.

[0051] A base plate 7 is provided below the interior surrounded by the steel pipe sheet pile 3 . The bottom plate 7 is made of concrete, for example.

[0052] In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com