Fine dried noodle cutting machine

A noodle cutting machine and vermicelli technology, applied in the fields of dough cutting machinery, baking, food science, etc., can solve the problems of missed cutting and repeated cutting, different lengths of vermicelli, and fragile vermicelli, etc., to improve packaging quality and reduce production. cost, the effect of reducing the phenomenon of broken noodles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

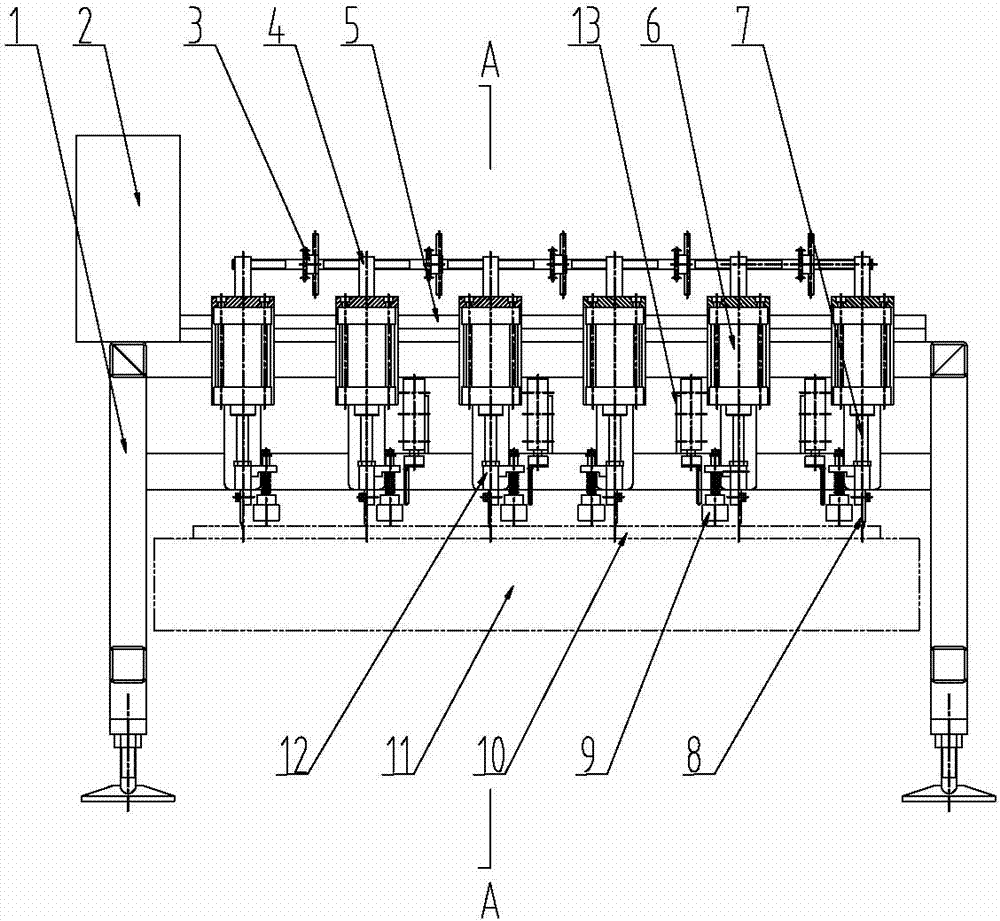

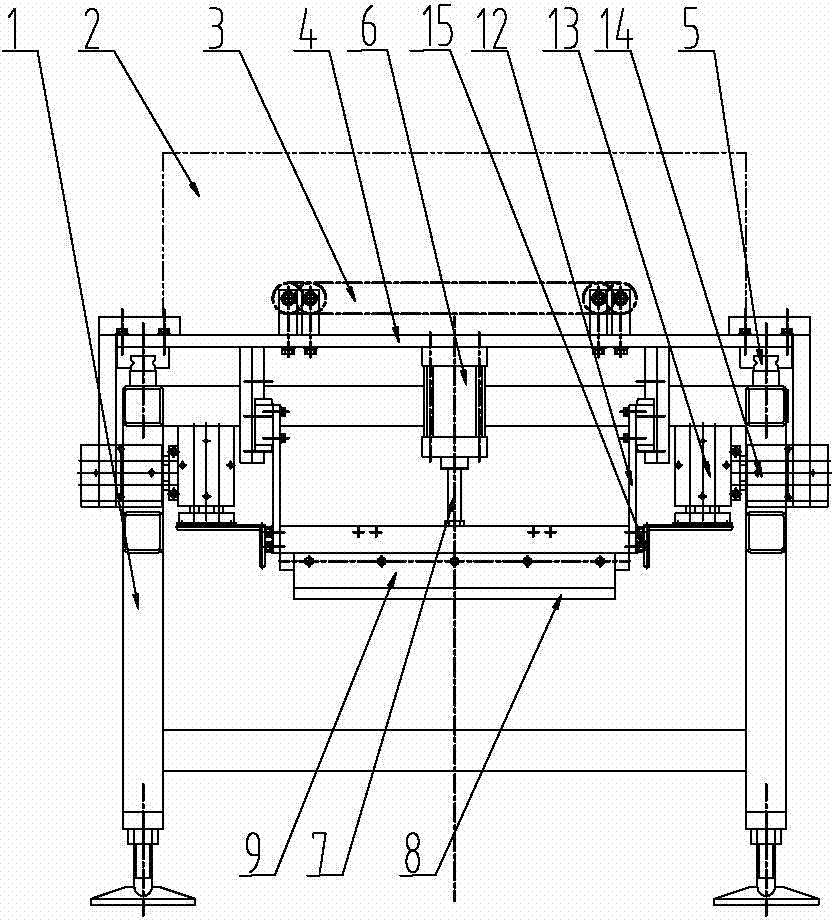

[0017] Depend on figure 1 , figure 2 It can be seen that a noodle cutting machine comprises a frame 1, on which a conveyor belt 11 for conveying long noodles 10 is provided, on which an electric control mechanism 2 and 1 to 12 cutter frames 4 ( There are 6 in this embodiment), the knife rest 4 is provided with 1 to 12 knife rests 12 driven by cylinders (6 in this embodiment), the knife rest 12 is provided with a noodle cutter 8 and a noodle pressing mechanism 9, In order to prevent the long noodles 10 from being scattered when cutting, the noodle pressing mechanism 9 with an elastic mechanism will first press the long noodles 10 while the noodle cutter 8 is cutting the noodles; , Cut the long noodles into 10 sections into the length of the finished noodles.

[0018] The cylinder barrel 6 of the air cylinder is installed on the cutter frame 4 of the present invention, and the knife frame 12 is connected with the piston rod 7 of the air cylinder.

[0019] For simple structur...

Embodiment 2

[0032] The present embodiment is provided with three cutter frames 4, and each cutter frame 4 is provided with three knife frames 12 driven by one air cylinder, and the knife frame 12 is provided with a noodle cutter 8 and a noodle pressing mechanism 9.

[0033] When cutting noodles, the electric control mechanism 2 controls the action of each cylinder, and the long noodles 10 are pressed down and cut into noodle sections of the length of finished noodles at one time. The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com