Diaphragm pressing type maxillary traction device and manufacture method thereof

An anterior traction and manufacturing method technology, which is applied to the lamination type anterior traction device, the lamination type anterior traction device for orthodontics and the manufacturing field thereof, can solve the problem that the anterior crossbite appliance is easy to loosen and fall off, and the bone correction effect is weak. , dental caries and other problems, to achieve the effect of increasing retention, excellent elasticity, and less foreign body sensation in the oral cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment

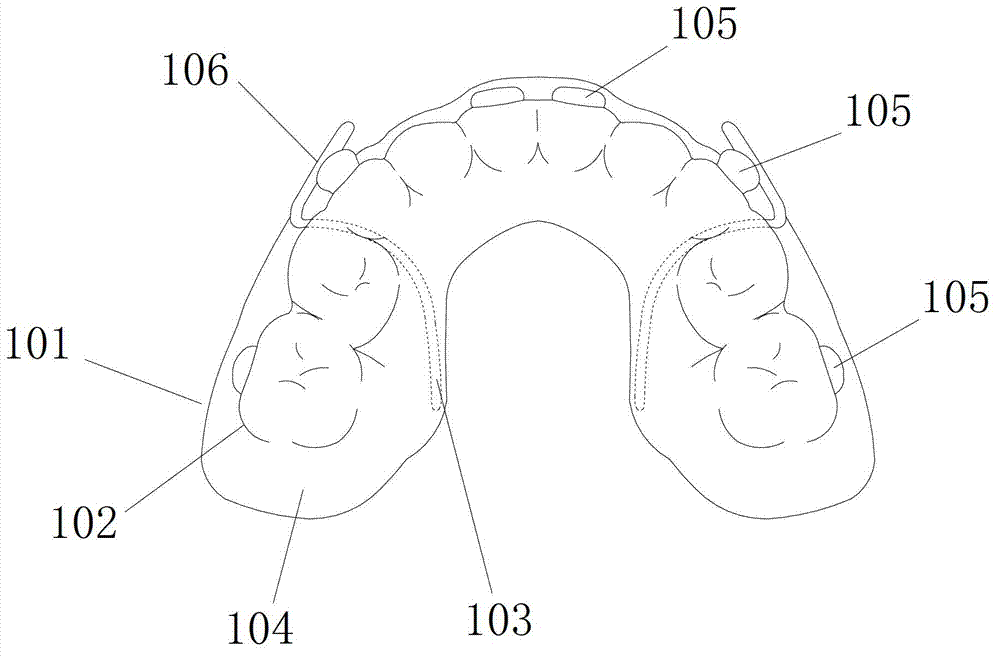

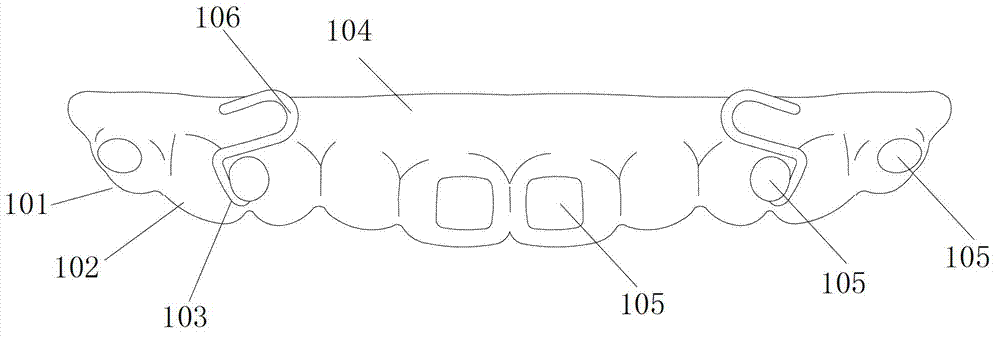

[0027] The film-pressed front traction device of the present invention includes a maxillary pad 101 and a traction hook 103, and the traction hook 103 is made of medical stainless steel. Such as figure 1 , figure 2 As shown, the base 102 of the maxillary pad 101 is provided with a membrane 104 covering the maxillary dental arch, part of the lip and buccal mucosa and most of the palatal mucosa, covering the maxillary dental arch, part of the lip and buccal mucosa and most of the palatal mucosa The purpose is to play a stereotyped orthodontic effect on the upper jaw, and the coverage area is also determined according to the individual condition, condition and comfort of the patient. The base 102 is respectively provided with a retention protrusion 105 on the buccal surface of the deciduous central incisors, deciduous canines and second deciduous mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com