Rear retaining device of thin plate shearing machine

A shearing machine and material supporting technology, which is applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve problems such as the inability to achieve horizontal material support, uneven support brackets, and sagging of sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

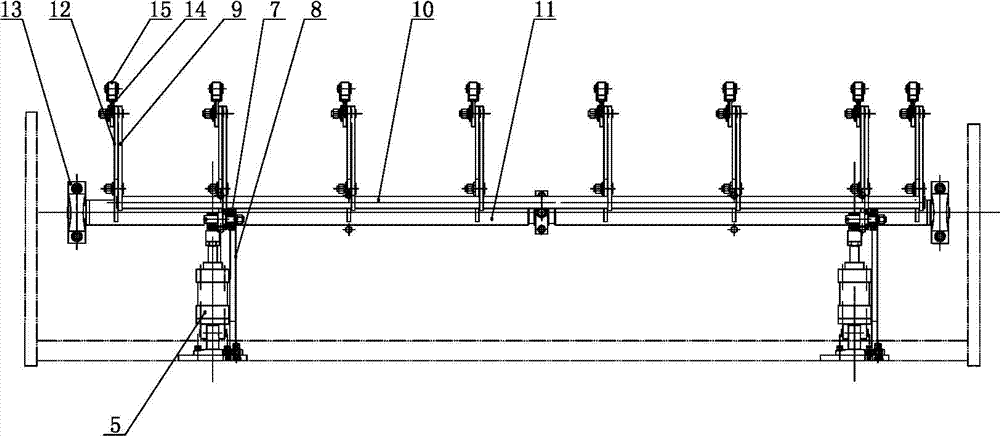

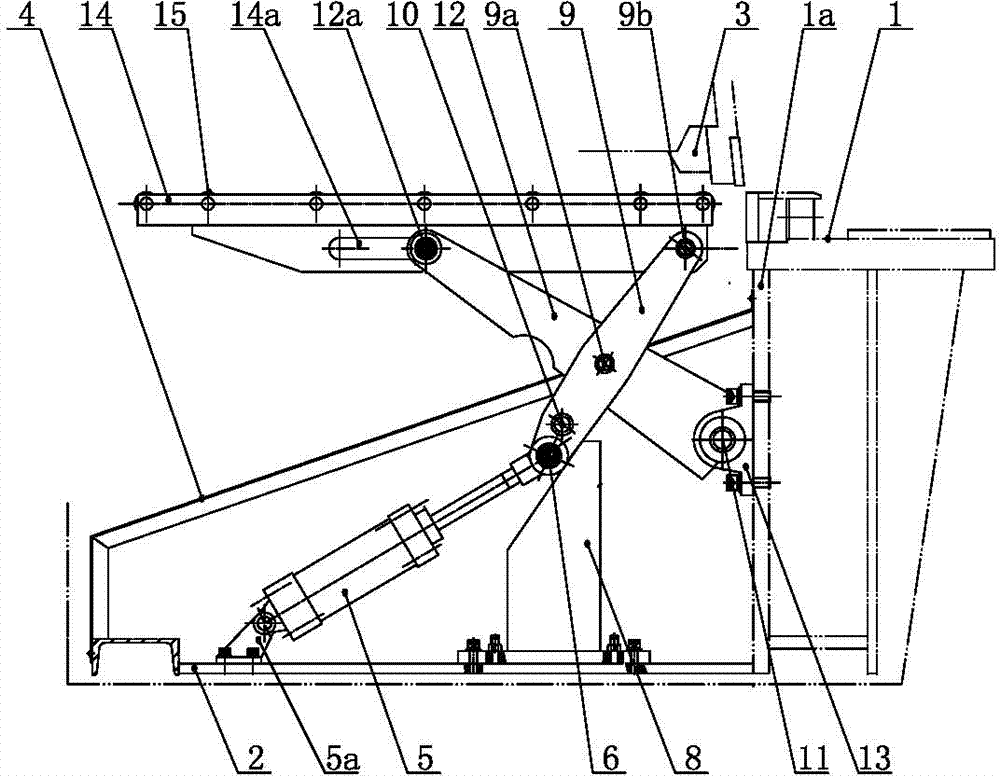

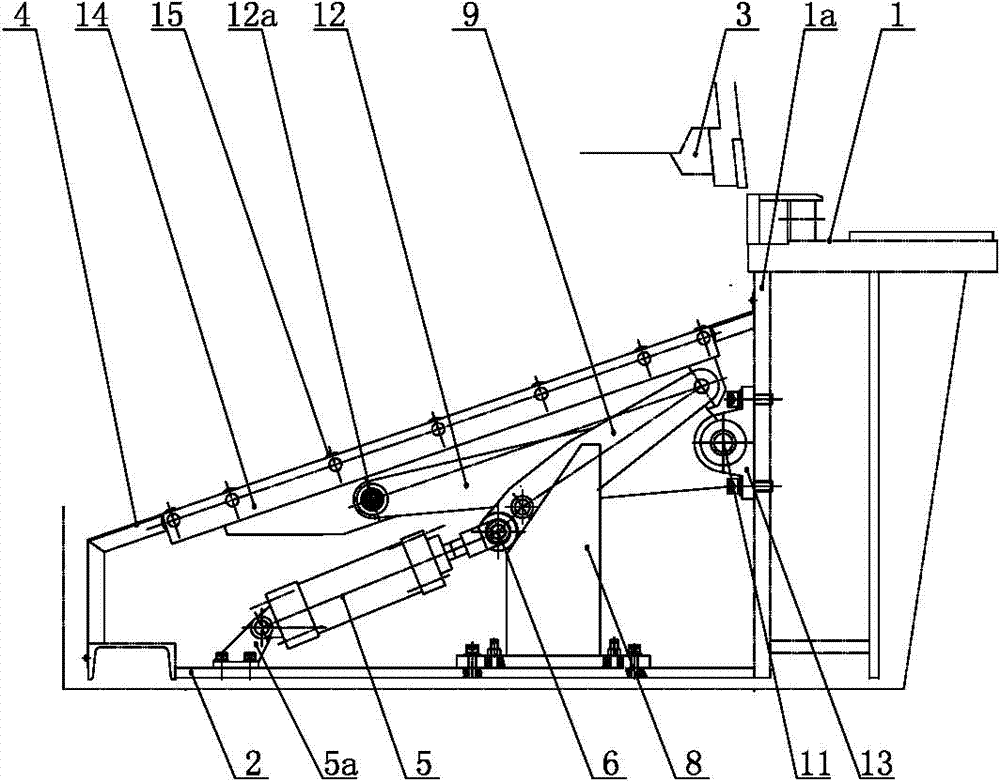

[0021] like figure 1 , figure 2 and image 3 As shown, the rear supporting device of the thin plate shearing machine of the present invention includes a workbench 1, a base 2, a knife rest 3, a supporting bracket 14, a slide plate 4, a cylinder 5, a bearing seat 13 and a rotating shaft 11, and a knife rest 3 Located above the workbench 1, there is a workbench vertical plate 1a in front of the workbench 1, the base 2 extends horizontally forward along the bottom of the workbench vertical plate 1a, and two cylinders 5 are arranged symmetrically along the width direction of the workbench. The rotating shaft 11 extends along the width direction of the vertical plate of the workbench, and the two ends are supported on the bearing seat 13, the bearing seat 13 is fixed in the middle of the height direction of the vertical plate of the workbench, and the slide plates 4 are separated on both sides in the width direction of the front of the workbench And stand in parallel, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com