Die for integrally forming I-shaped reinforcement composite material wall plate

An integral molding, composite material technology, applied in the field of resin matrix composite material molding, can solve the problems of increasing tooling cost, profile deviation assembly coordination, increasing material and process cost, etc., and achieves the effect of solving the problem of insufficient pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

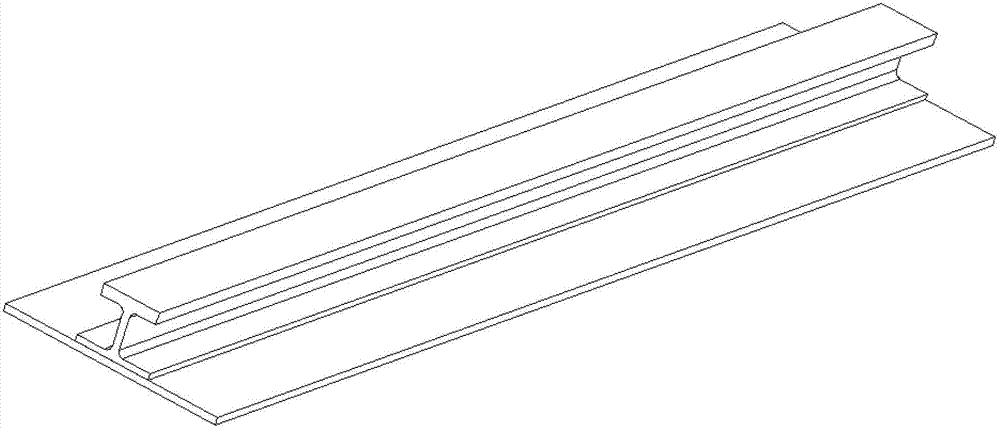

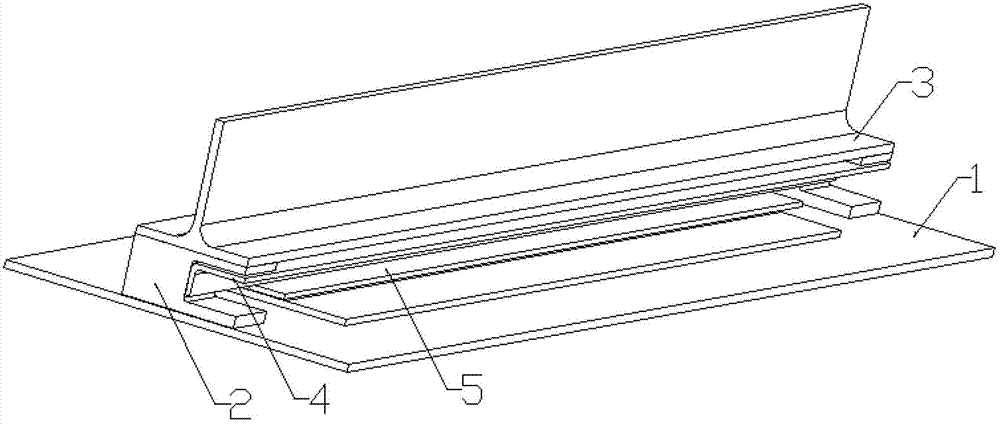

[0032] Embodiment 1: a typical structure such as figure 1 , there is a "work" type reinforcement on the outer skin 7, the overall size is 900mm x 300mm x 50mm (length x width x height), the material is U3160 / QY9512, and the "work" type reinforcement is under the suture technology. The flanges are stitched to the skin and then integrally formed by the RFI process. The surface accuracy of the "I" type reinforced upper flange is required to reach ±0.12mm. We have adopted the solution of the present invention.

[0033] (a) Design the shape mold 1 according to the shape of the reinforced wall plate, widen 50mm on one side in the horizontal direction, and lengthen 100mm in one side in the vertical direction.

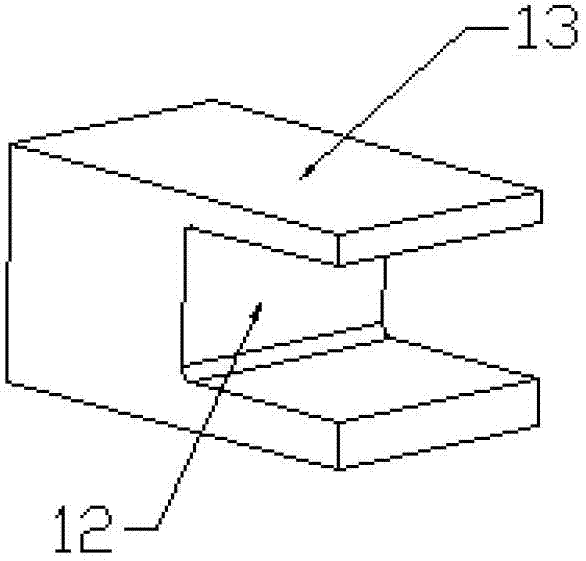

[0034](b) The beam 3 is designed on the outer surface of the reinforced upper flange, and the beam is designed as a "T"-shaped cross-section with better rigidity. Based on the requirements, the profile deviation is not greater than ±0.1mm. The edge of the 3-shaped surface ...

Embodiment 2

[0041] Example 2: The structure of the "I" type reinforced wall plate test piece is as follows Figure 6 , the material is G0827 / QY9512, which is integrally formed by RFI technology. The overall size is 900mm×520mm×105mm (length×width×height), the reinforced wallboard is a wallboard structure with 5 “work” section reinforcements 8 in the longitudinal direction on the skin 7, and the 5 reinforced upper flanges and The metal parts at both ends are required to be assembled with the upper skin. In order to ensure the coordination and consistency of the outer surface 10 of the upper flange of the 5 "work" type ribs and the metal parts at both ends and the inner surface of the upper skin, the 5 "work" The accuracy of the outer surface 10 of the "type reinforced upper flange must be controlled within ±0.2mm. Here we adopt the mold scheme of the present invention, such as Figure 7 shown.

[0042] (a) Considering that the shape of the stiffened plate is flat, the shape mold 1 is des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com