Method for preparing rare-earth compound with NaZn13 structure by solid state diffusion

A rare earth compound, solid-state diffusion technology, applied in chemical instruments and methods, magnetic objects, heat exchange materials, etc., can solve the problem of poor processing performance of structural rare earth-iron-cobalt-silicon compounds, can not meet the requirements of magnetic refrigerator material shape, The problem of high cost and the effect of avoiding the difficulty of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

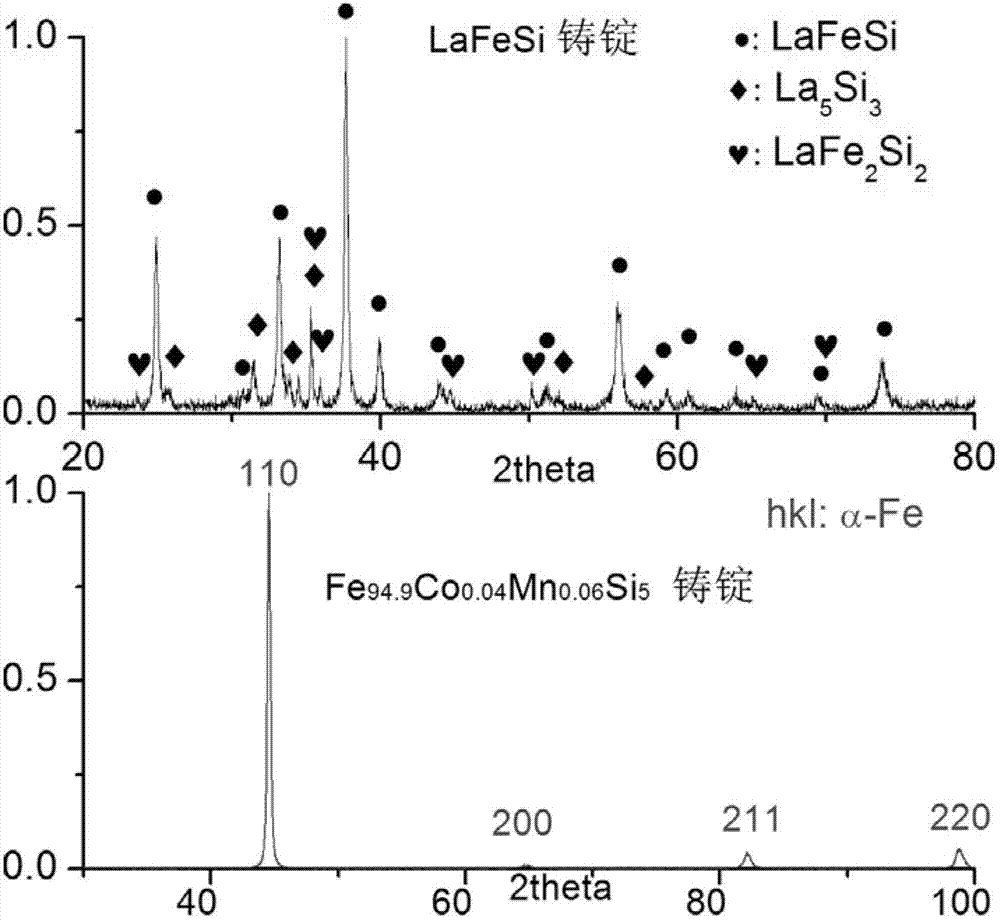

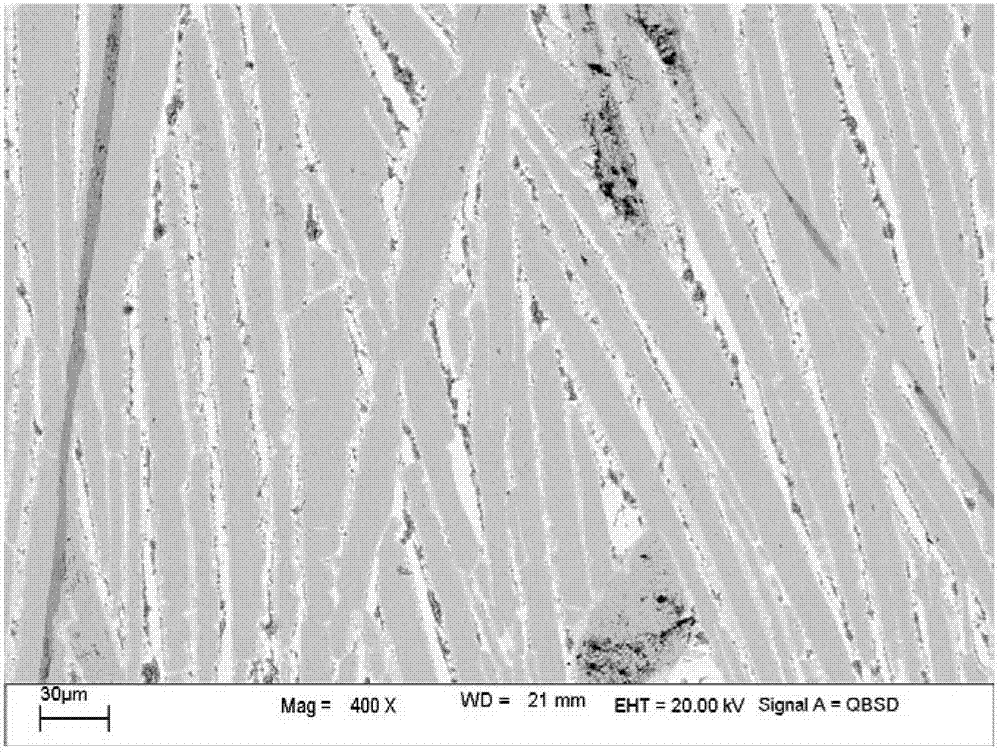

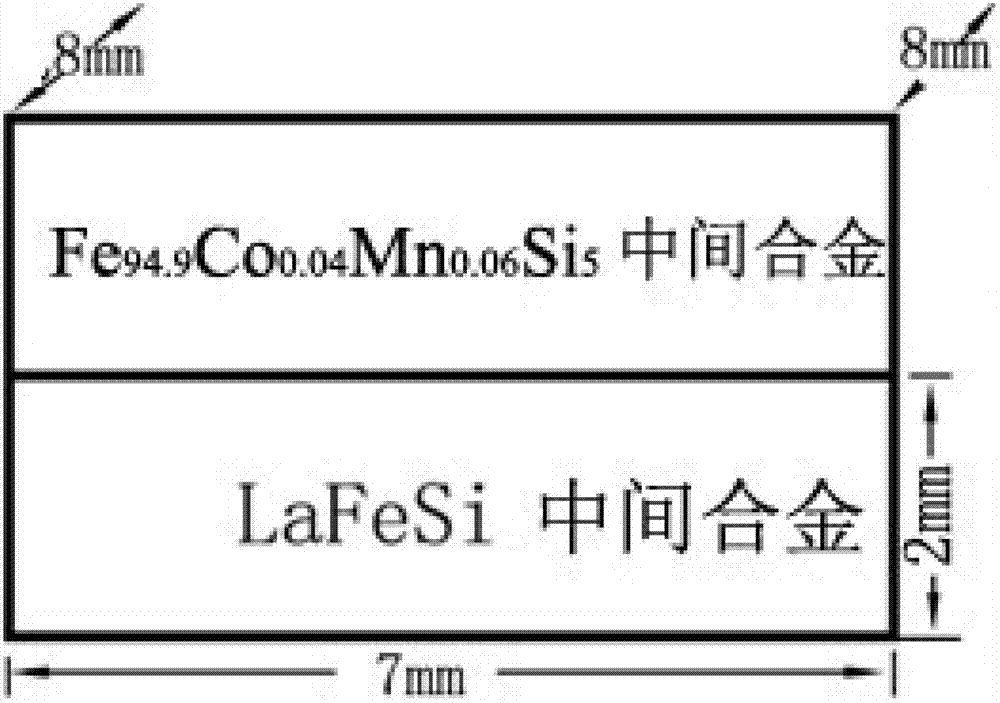

[0043] Using elemental La, Fe, Si, Mn, Co according to LaFeSi and Fe 94.9 co 0.04 mn 0.06 Si 5 Ingredients formulated master alloy ingots. The X-ray diffraction pattern of the above-mentioned master alloy ingot is as follows: figure 1 . The backscattering pattern of the above-mentioned LaFeSi master alloy ingot is as follows figure 2 . Depend on figure 1 and figure 2 It can be known that the above Fe 94.9 co 0.04 mn 0.06 Si 5 The master alloy ingot is a single α-Fe phase; the above LaFeSi master alloy ingot is made of La 5 Si 3 , LaFeSi and LaFe 2 Si 2 Three-phase composition. The above-mentioned master alloy ingots were processed into rectangular sheets of 2mm×7mm×8mm, sanded and polished so that the rectangular sheets of the above two master alloys all had a very smooth surface, and the surface roughness Ra was 1.6. Then the above-mentioned LaFeSi rectangular flakes and the above-mentioned Fe 94.9 co 0.04 mn 0.06 Si5 Rectangular sheets are superimposed ...

Embodiment 2

[0045] Using elemental La, Ce, Fe, Co, Cr, Si, C according to (Ce 0.05 La 0.95 )(Fe 0.95 co 0.05 )(Si 0.98 C 0.02 )

[0046] and Fe 96.98 Cr 0.02 Si 3 The ingredients are formulated into master alloy ingots. the above Fe 96.98 Cr 0.02 Si 3 The intermediate alloy ingot is cut into circular slices with a thickness of 2mm and a diameter of 15mm, and is ground and polished with sandpaper to make the Fe of the above-mentioned circular slices of thickness 2mm and diameter 15mm 96.98 Cr 0.02 Si 3 Both surfaces of the master alloy are smooth surfaces, and the surface roughness Ra is less than 1.6. Prepare thickness 5mm in addition, two above-mentioned (Ce 0.05 La 0.95 )(Fe 0.95 co 0.05 )(Si 0.98 C 0.02 ) intermediate alloy round flakes, and make the above two pieces (Ce 0.05 La 0.95 )(Fe 0.95 co 0.05 )(Si 0.98 C 0.02 ) round flakes of the master alloy have a smooth surface with a surface roughness Ra less than 1.6. Then the above two pieces (Ce 0.05 La 0.9...

Embodiment 3

[0048] Using elemental La, Pr, Fe, Mn, Cu, Si according to (Pr 0.05 La 99.95 )(Fe 99.94 mn 0.06 ) Si and Fe 94 Cu 1 Si 5 Composition Preparation of master alloy ingots. the above Fe 94 Cu 1 Si 5 The intermediate alloy ingot is processed into a disc with a diameter of 20mm with a through hole, and the diameter of the through hole is 1.0~1.3mm; the above (Pr 0.05 La 99.95 )(Fe 99.94 mn 0.06 ) Si is processed into a disc with a diameter of 22mm. Then sand and polish the above Fe 94 Cu 1 Si 5 Both surfaces of the wafer and the above (Pr 0.05 La 99.95 )(Fe 99.94 mn 0.06 ) One surface of the Si wafer is a very smooth plane with a surface roughness Ra0.05 La 99.95 )(Fe 99.94 mn 0.06 ) The above-mentioned Fe is sandwiched between the Si wafers 94 Cu 1 Si 5 Discs are superimposed and fixed to form a planar diffusion couple with a sandwich structure, such as Figure 8 , a sandwich-structured planar diffusion couple with a smooth bonding plane was prepared. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com