Variable intake vortex channel structural device

A swirl and flow channel technology, applied in the field of variable intake swirl flow channel structure devices, can solve the problems of inability to adjust online, low eddy current intensity, etc., so as to increase the intake air swirl intensity and solve the problems of fuel economy and emission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

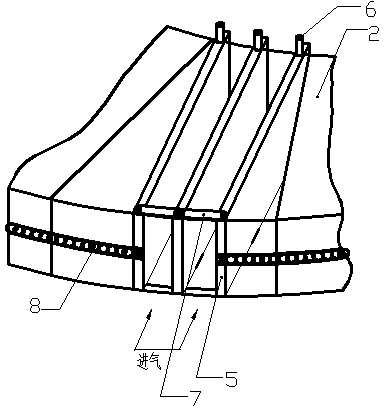

[0017] A variable intake vortex channel structure device, including a blade assembly 3, a driver 4, a blade 5, a rotating shaft 6, a connecting rod 7, a steel wire rope 8, a driving shaft 9, and a driving rod 10;

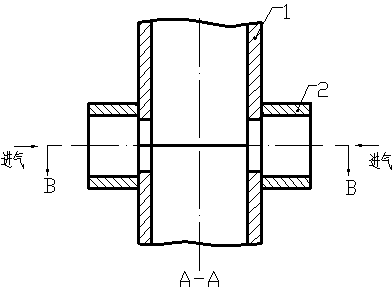

[0018] Such as figure 1 As shown, the device 2 of the present invention is installed on the outer circle of the diesel engine cylinder 1, and the air inlet of the device 2 is aligned with the air inlet of the diesel engine cylinder 1 to form a diesel engine air inlet flow passage.

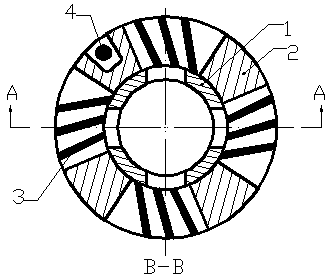

[0019] Such as figure 2 As shown, the air inlet of device 2 is fan-shaped, the air inlet is aligned with the air inlet of diesel engine cylinder 1, and is evenly distributed along the circumference of quasi-diesel engine cylinder 1; blade assembly 3 is installed in the air inlet of device 2, and A driver 4 is installed between the two air inlets, and the drive shaft in the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com