Anti-stripping pipe clamp

A pipe clamp and anti-dropping technology, which is applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, connecting components, etc., can solve the problems of low assembly efficiency, occupying space for transportation and placement, and loss of elastic expansion characteristics, etc., to achieve simple structure, Easy to use and guarantee the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

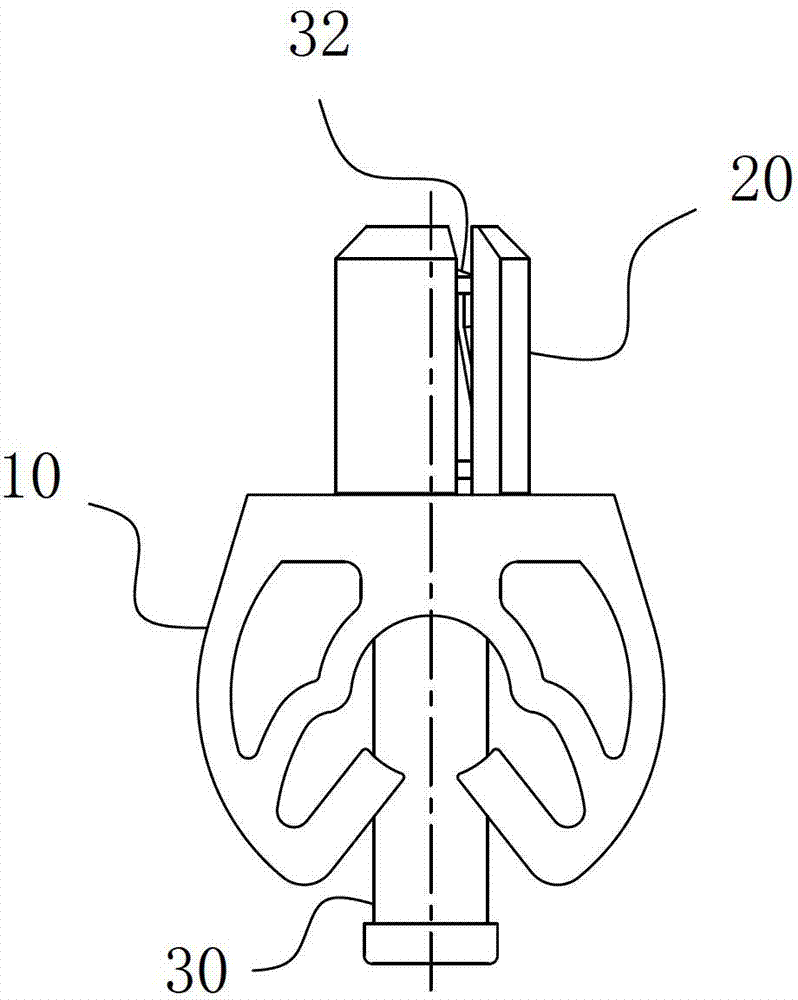

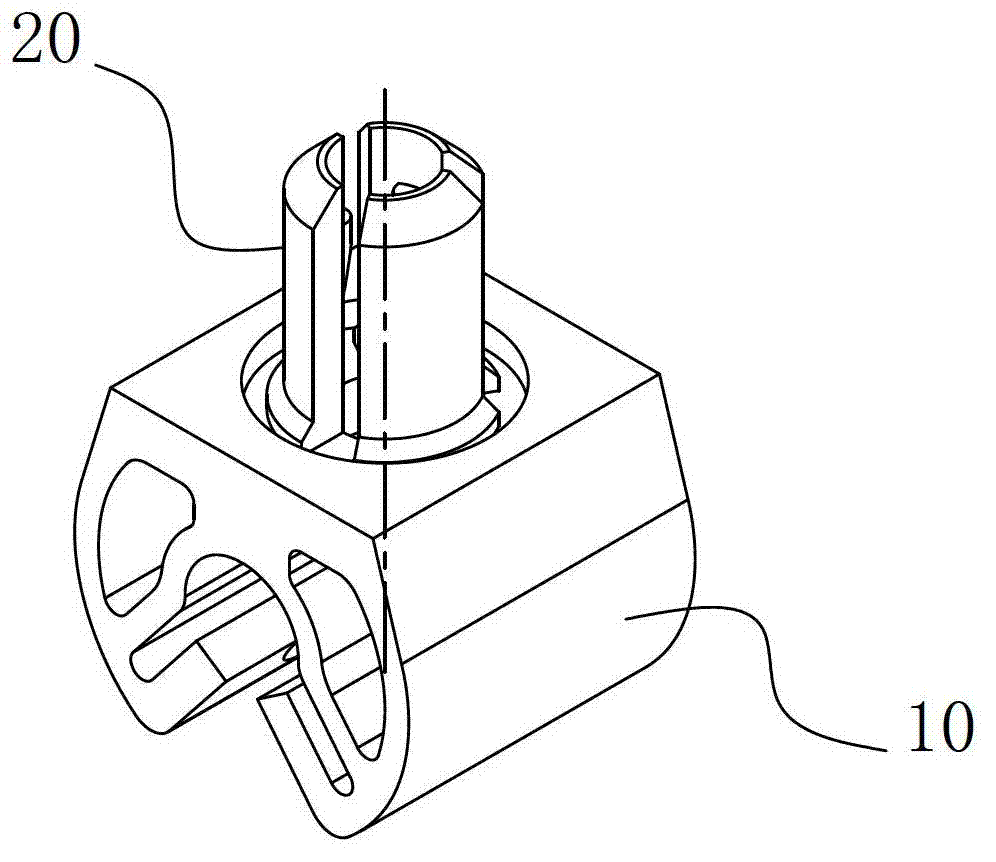

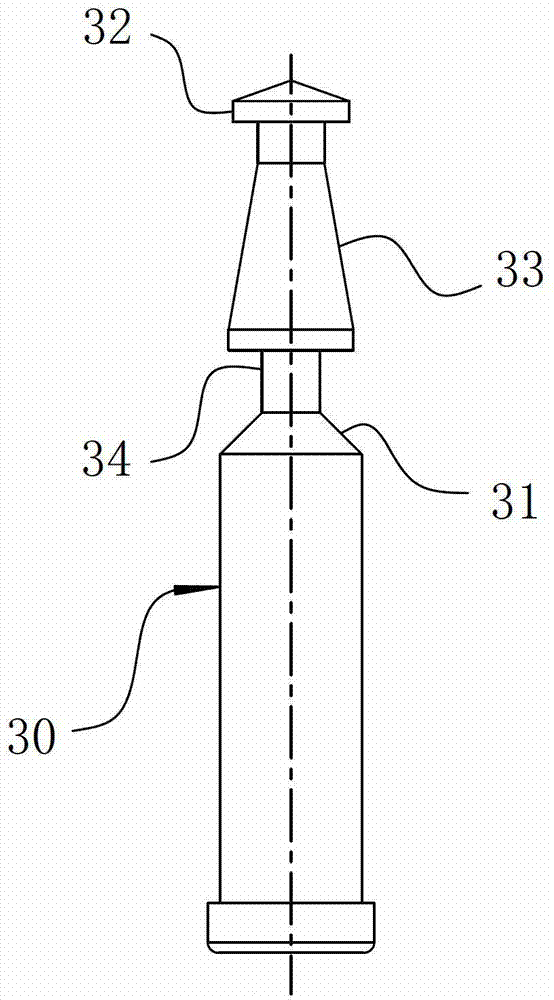

[0010] An anti-loosening pipe clamp, including a clamp mouth 10 for clamping pipe fittings, and the other side of the clamp mouth 10 is opposite to the clamping interface A for clamping pipe fittings. A positive tapered through hole 21 that penetrates the plug post 20 is arranged along its axis from its top end to its root. The through hole 21 constitutes the hollow expansion sleeve structure of the plug post 20 and the plug post 20 and A plug-in expansion nail is formed between the fixing parts of the vehicle body. The pipe clamp also includes an expansion pin 30 for forming a plug-in fit with the expansion sleeve-like plug-in column 20. The plug-in end 31 on the expansion pin 30 is A gear part 32 is arranged forward along its axis. The gear part 32 forms a one-way gear fit with the top end of the insertion post 20. The distance between the gear part 32 on the expansion pin 30 and its insertion end 31 is greater than or equal to the length of the through hole 21 .

[0011] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com