X-ray exposure control method and device and X-ray exposure system

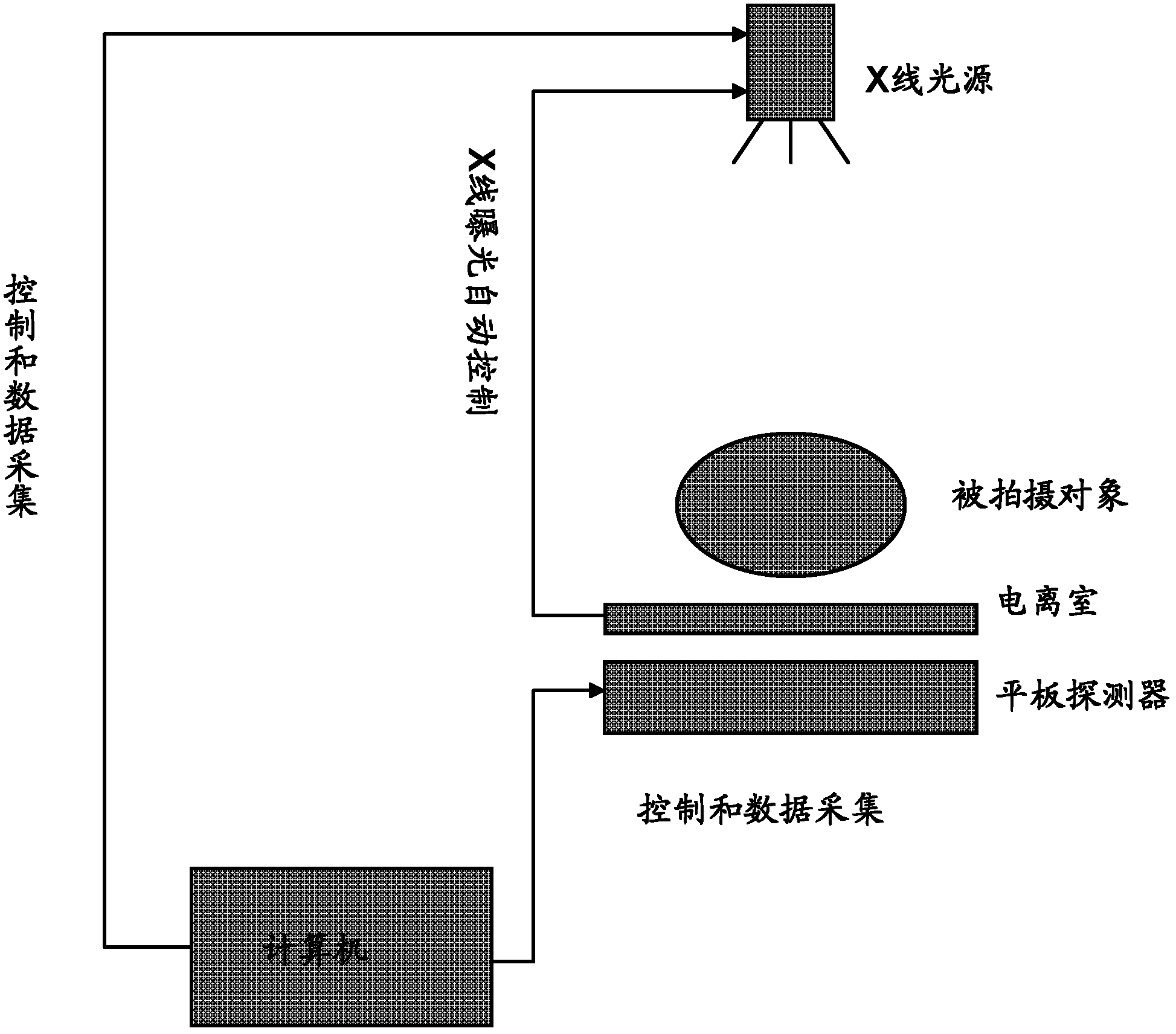

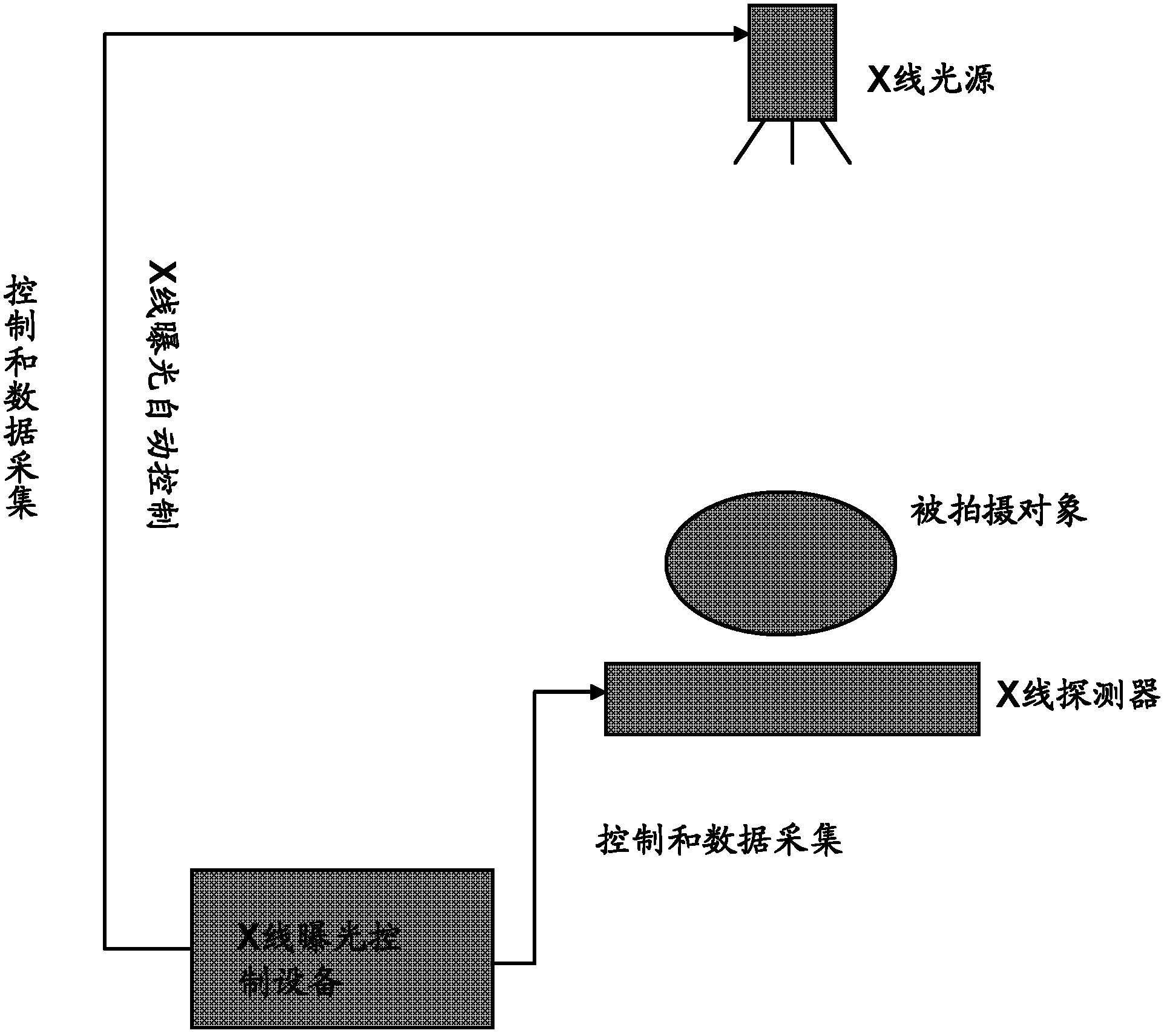

An exposure control and equipment technology, applied in the field of X-ray exposure, can solve the problems of inability to convert X-ray dose, waste of X-ray exposure dose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

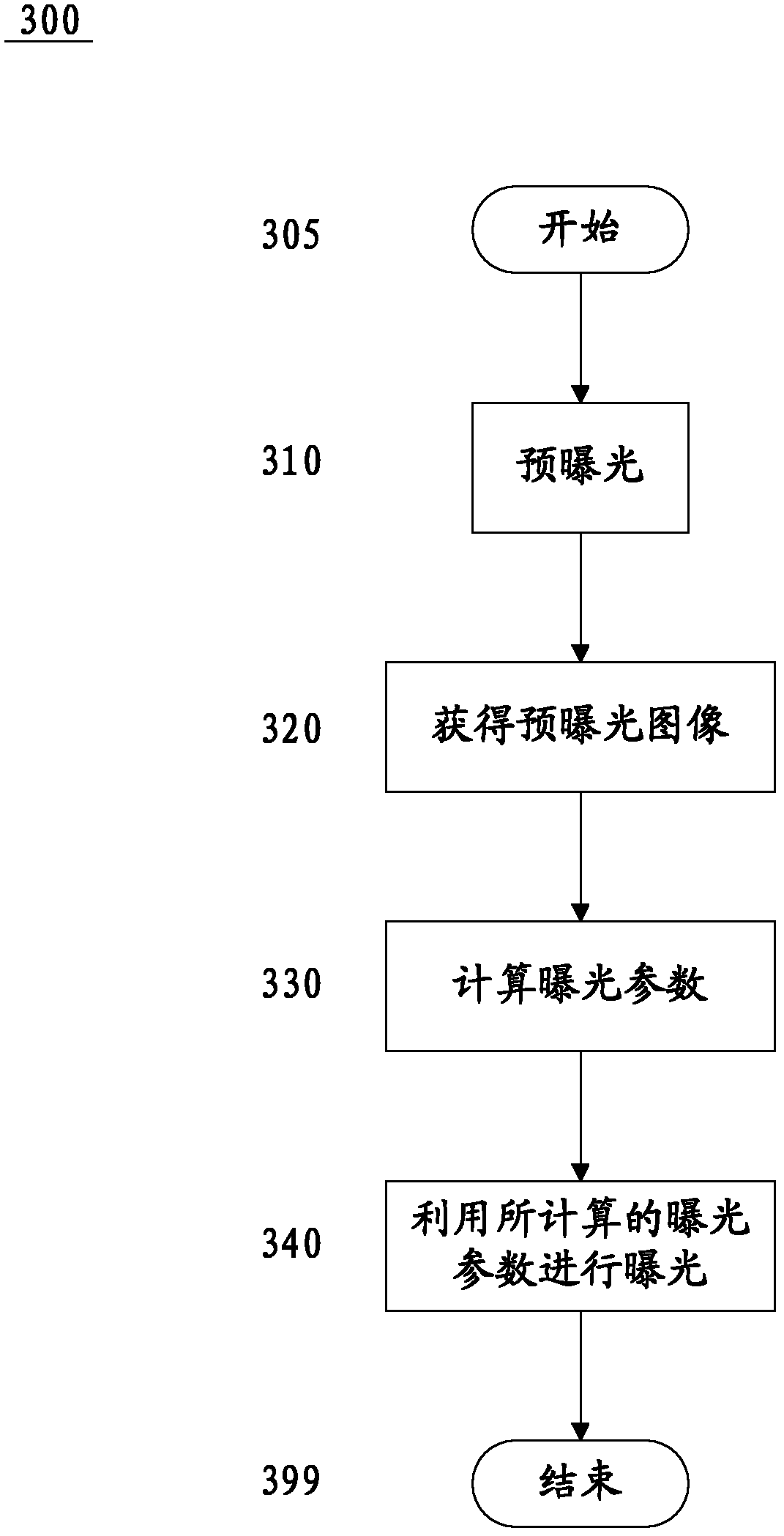

[0071] In step S505, the X-ray exposure control method according to the first embodiment of the present invention starts to operate.

[0072]In step S510, pre-exposure is performed on the subject, and the pre-exposure tube voltage, pre-exposure tube current and pre-exposure time are selected as described above.

[0073] In step S515, after the pre-exposure is completed, the X-ray exposure is stopped.

[0074] Then, in step S520, the pre-exposure image generated by the pre-exposure is obtained as described above.

[0075] In step S530, according to the pre-exposure image, the exposure time required for exposing the subject is calculated, while keeping the pre-exposure tube voltage and pre-exposure tube current unchanged. Specifically, a given area is selected in the obtained pre-exposure image, and the gray value of each pixel in the selected given area is averaged so as to obtain the average gray value of the given area, using the Divide the desired exposure image grayscale ...

no. 2 example

[0079] Similar to the first embodiment, in step S515, the X-ray exposure is stopped after the pre-exposure is completed, and in step S520, a pre-exposure image generated by the pre-exposure is obtained.

[0080] In step S530, according to the pre-exposure image, the exposure time and the exposure tube voltage required for exposing the subject are calculated, while keeping the pre-exposure tube current unchanged. Specifically, the required exposure tube voltage is determined according to the imaging size of the subject in the pre-exposure image, or according to the grayscale value of each pixel in a given area in the pre-exposure image. Also, the exposure time required to expose the subject is calculated as described in the first embodiment.

[0081] Next, in step S540, the subject is re-exposed using the exposure tube voltage, the exposure tube current equal to the pre-exposure tube current, and the exposure time.

no. 3 example

[0083] Similar to the first and second embodiments, in step S515, the X-ray exposure is stopped after the pre-exposure is completed, and in step S520, a pre-exposure image generated by the pre-exposure is obtained.

[0084] In step S530, according to the pre-exposure image, the exposure time, exposure tube current and exposure tube voltage required for exposing the subject are calculated. Specifically, the required exposure tube voltage is determined according to the imaging size of the subject in the pre-exposure image, or according to the grayscale value of each pixel in a given area in the pre-exposure image. In addition, the gray value of each pixel in a given region of the pre-exposure image is averaged to obtain the average gray value of the given region, and the required gray value of the exposed image is divided by the given region In order to obtain a dosing factor, the product of the pre-exposure time and the pre-exposure tube current is multiplied by the dosing fact...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap