Air core reactor

An air-core reactor and anti-creepage technology, which is applied in the direction of instruments, scientific instruments, electrical component structure associations, etc., can solve the problems of reduced reactor life, large randomness, and failure to detect hidden dangers in time, so as to improve the operating life and avoid Burnout accidents, the effect of lowering the internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

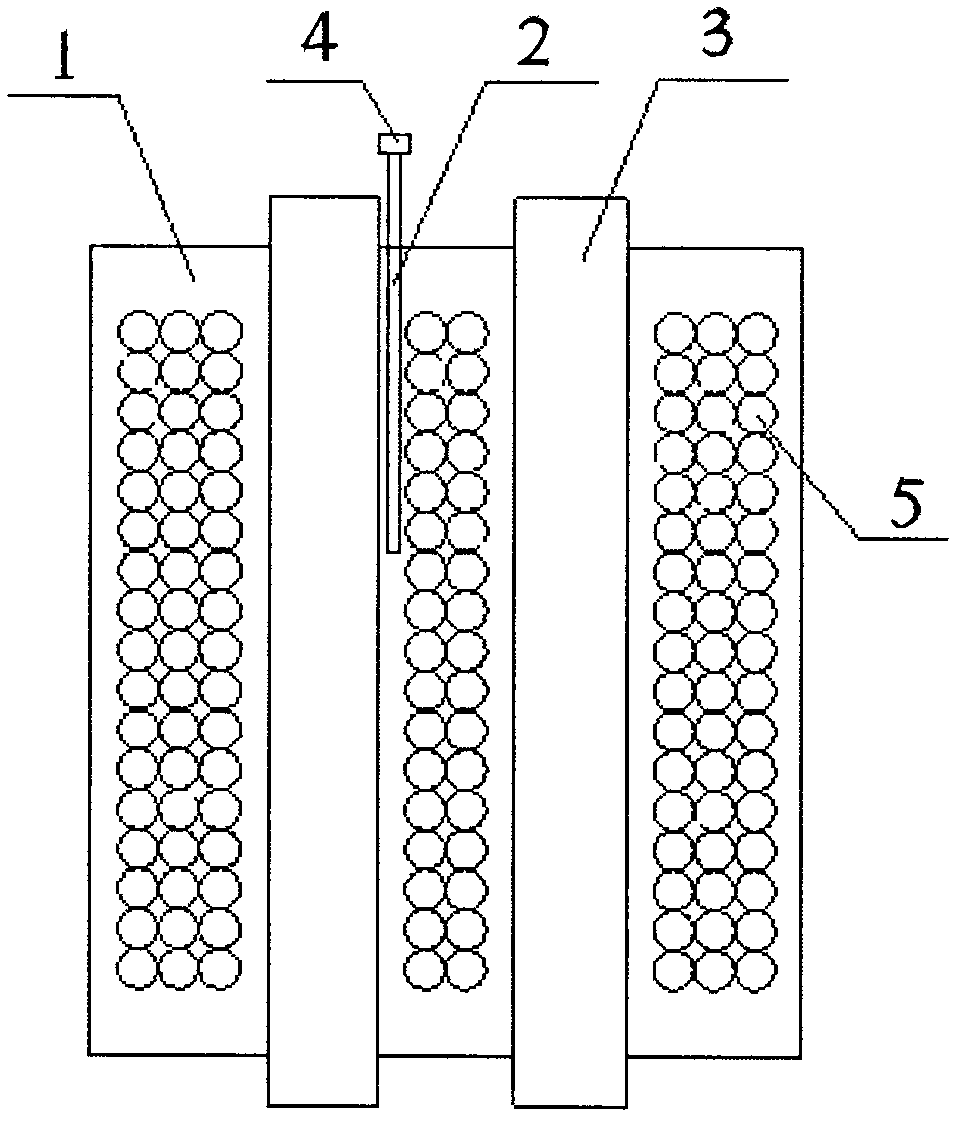

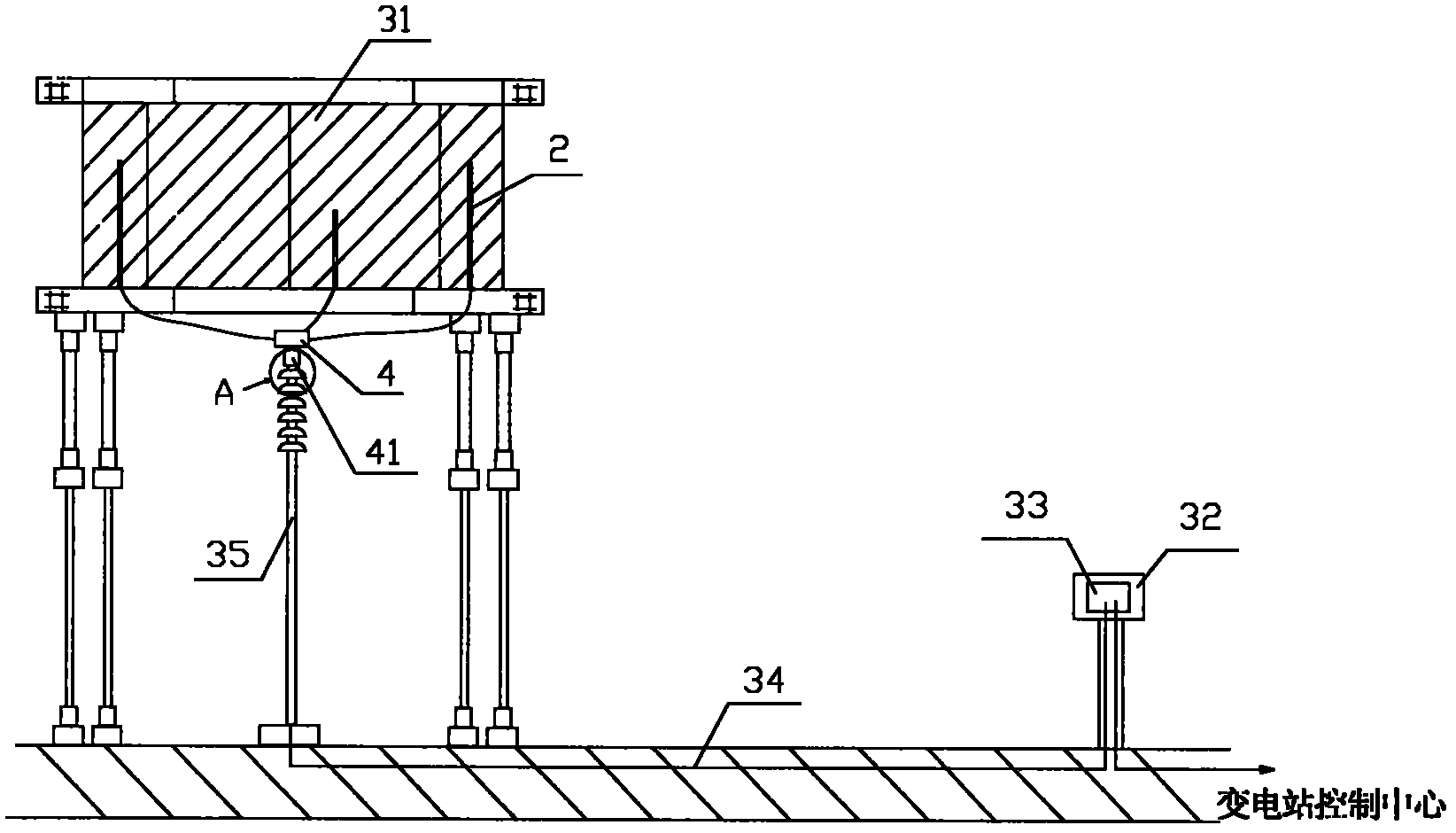

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the air-core reactor provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0024] When the air-core reactor works for a long time, the heat transfer process is very complicated. The heat transfer inside the coil is heat conduction, and the heat transfer mode between the package and the package and between the winding and the outside is convection, heat conduction and radiation. Among them, the heat transfer between the winding and the outside world is dominated by convective heat transfer.

[0025] For such a complex heat dissipation problem, empirical formulas are often used for calculation when manufacturing air-core reactors. The approximate empirical formula for the average temperature rise of the air-core reactor is:

[0026] τ=Kθ(q)β=Kθ(p / s)β

[0027] τ-winding temperature rise (K);

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com