Conveying device for conveying isolated long workpieces

A technology for conveying devices, workpieces, applied in the direction of conveyors, transport and packaging, needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

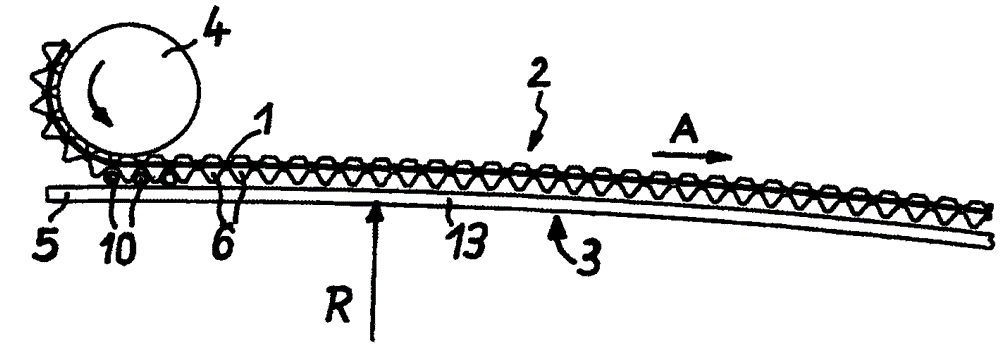

[0025] figure 1 A partial conveying device for elongated workpieces such as nail blanks, tubes, bolts, pins or the like is shown in substantially great detail, wherein the device has a continuous toothed belt 1 and a relatively long track 2 running almost straight, The conveying function is performed along this track.

[0026] Coordinated with this track 2 in the direction of the toothed belt 1 (curve radius R) is the guide rail 3 which runs over its extension and bends, albeit only at a small angle.

[0027] The toothed belt 1 is guided to the figure 1 Around the center left-hand side wheel 4 to drive its components intermittently, where in figure 1 The only defined curvature of the toothed belt 1 around the deflection wheel 4 is shown in the schematic diagram of FIG.

[0028] On this side, the end region 5 extends the guide rail 3 somewhat beyond the position of the deflection wheel 4 .

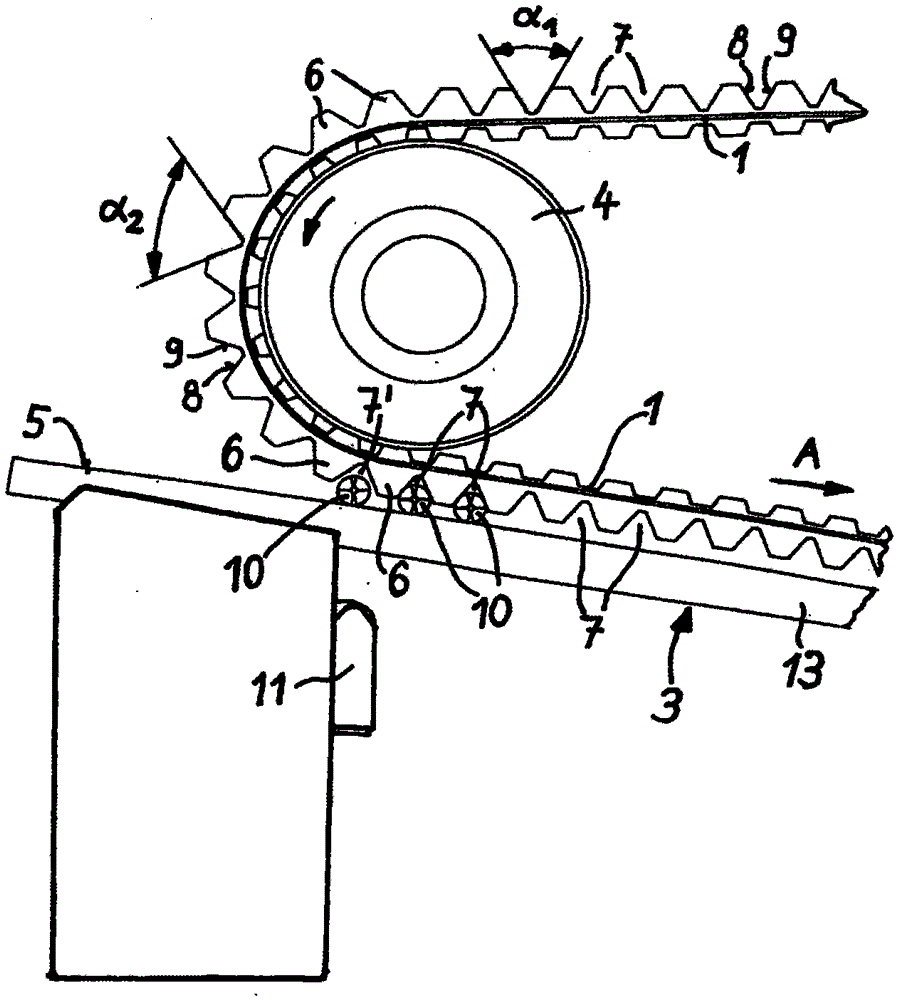

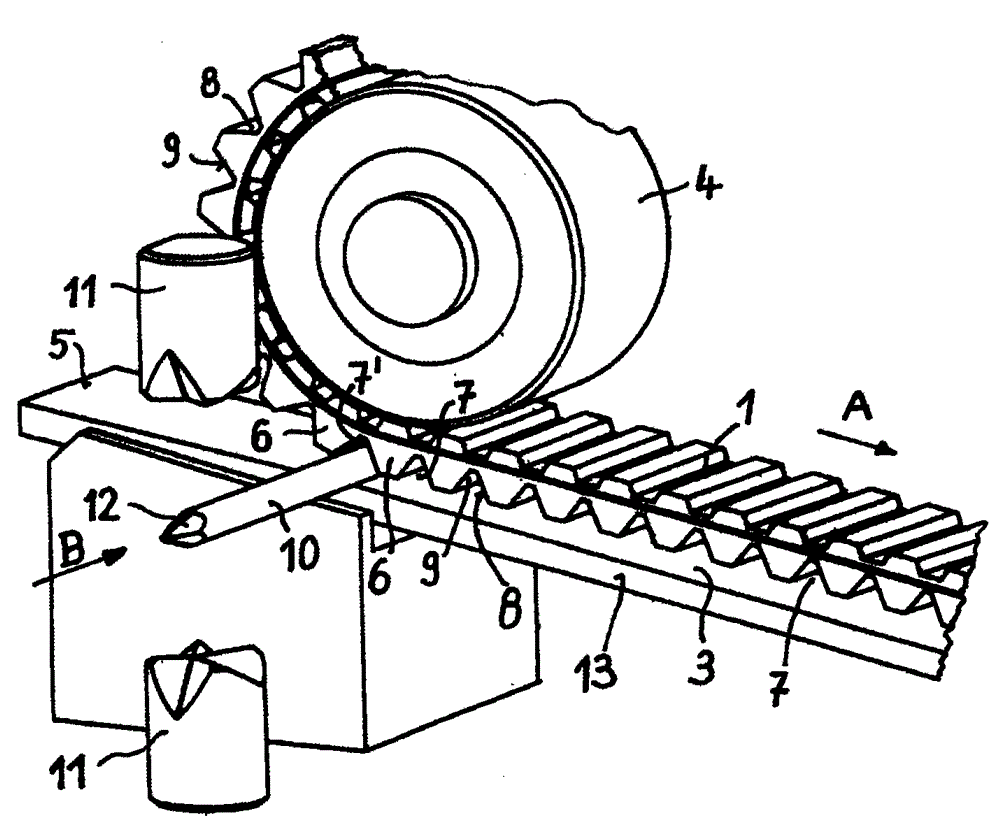

[0029] now refer to figure 2 , to display figure 1 The enlarged part, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com