Torsion beam type suspension

A torsion beam and suspension technology, applied in the field of torsion beam suspension, can solve problems such as discomfort and low-frequency vehicle driving noise, and achieve the effect of ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described based on the drawings.

[0041] 【Example】

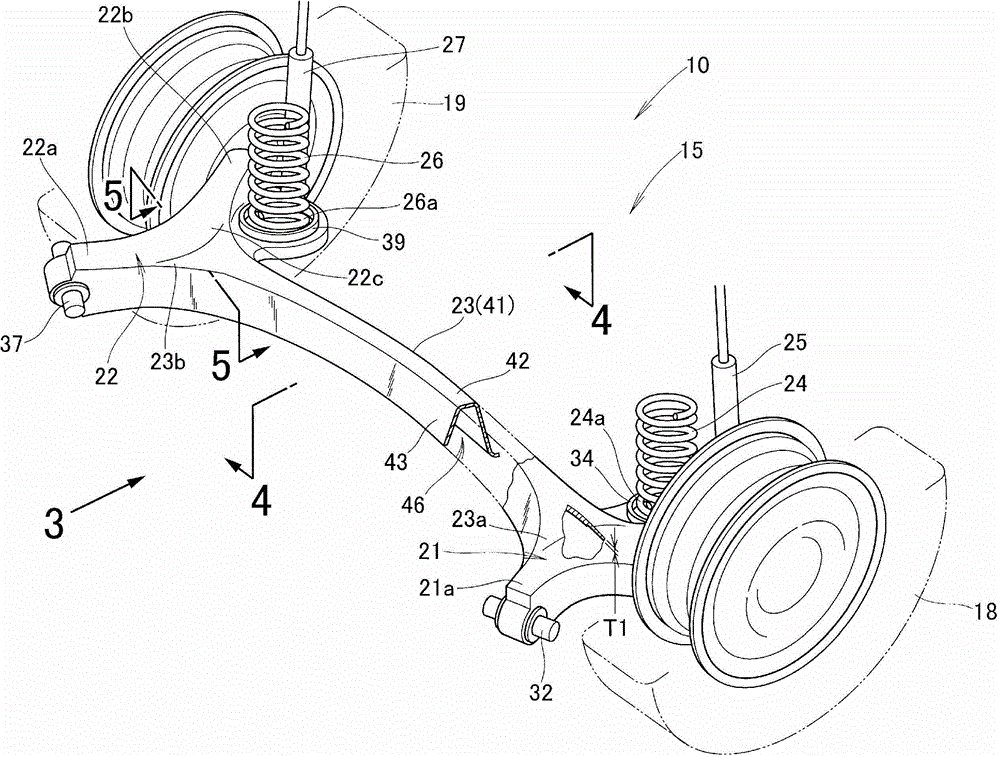

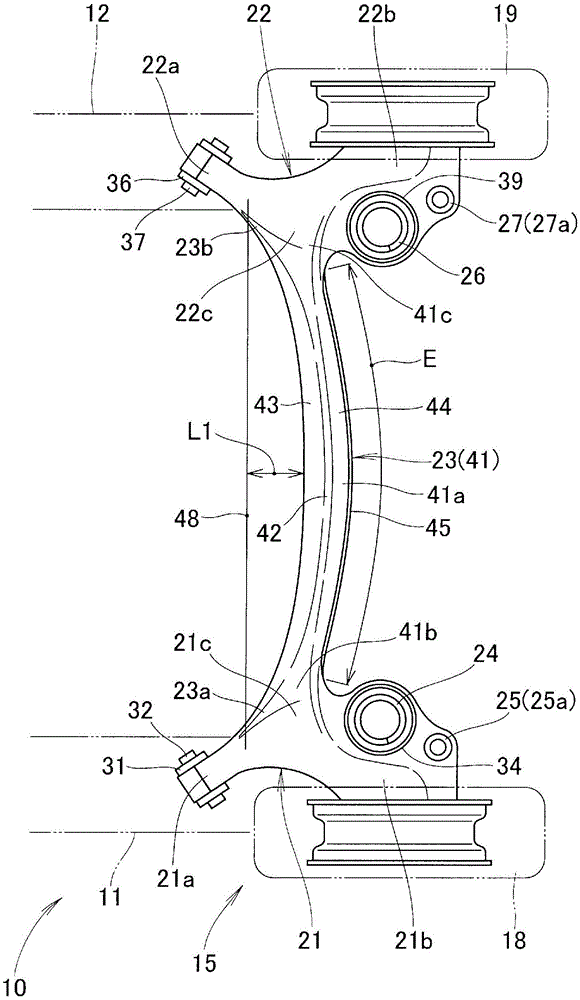

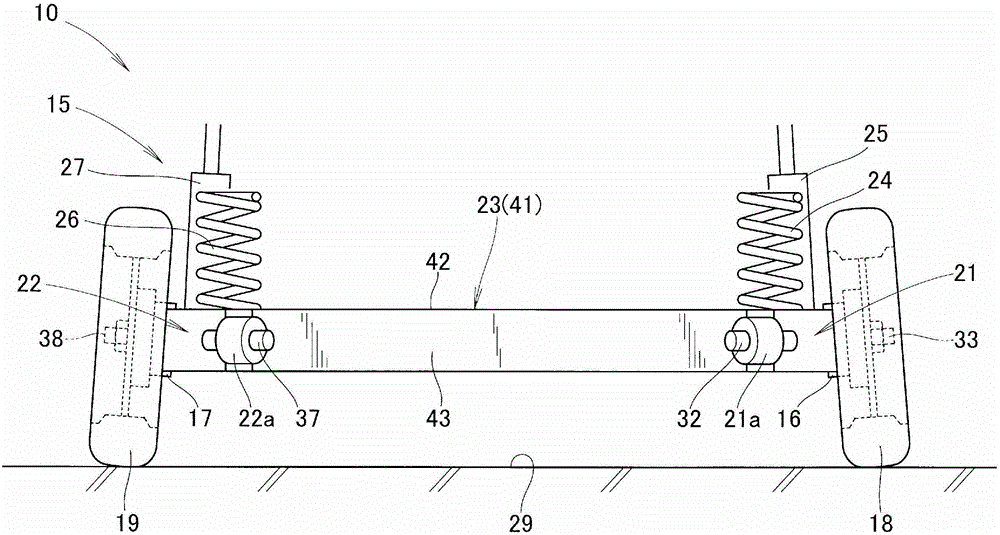

[0042] Such as Figure 1 ~ Figure 3 As shown, the vehicle body structure 10 includes: left and right side frames (body) 11, 12 arranged in the front-rear direction of the vehicle body; , 17 and the left and right rear wheels (wheels) 18,19 that are suspended on the torsion beam type suspension 15.

[0043]The torsion beam suspension 15 has: a left trailing arm 21 that is rotatably arranged at the bottom of the left side frame 11; a right trailing arm 22 that is freely rotatable at the bottom of the right frame 12; A torsion beam 23 extending between 22; a left spring 24 and a left shock absorber 25 for buffering supported by the left longitudinal arm 21; a right spring 26 and a right shock absorber 27 for buffering supported by the right longitudinal arm 22.

[0044] A front end (one end) 21 a of the left trailing arm 21 is pivotally supported by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com