Treatment device for recycling exhaust gas of gas station

A technology of waste gas recovery and treatment device, applied in the direction of removing smoke and dust, combustion methods, lighting and heating equipment, etc., can solve the problems of harsh working environment, polluted air, affecting human health, etc., and achieve the effect of avoiding exhaust gas escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

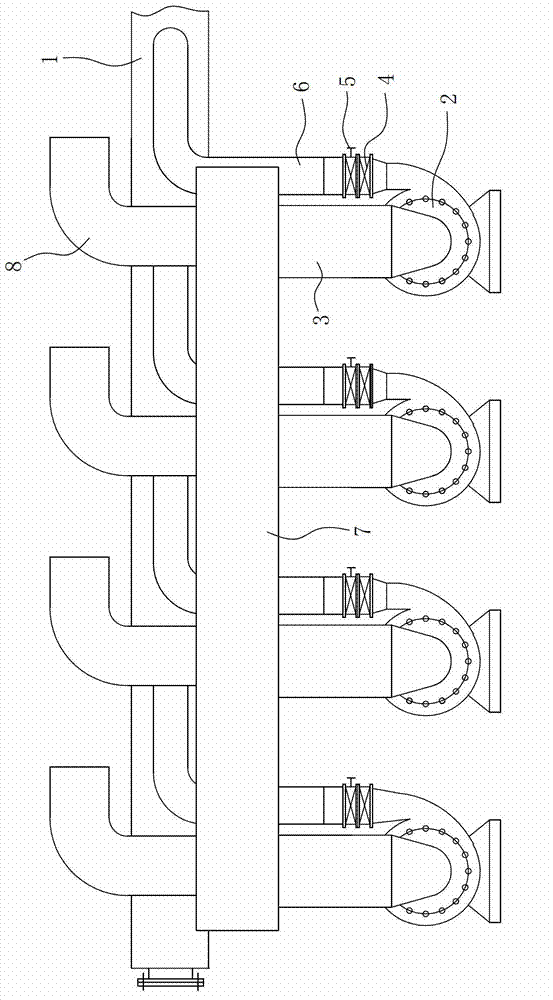

[0007] The technology will be further described below in conjunction with the accompanying drawings.

[0008] The waste gas recovery treatment device of the gas station in this embodiment includes a main air supply pipe 1 and a process blower 2, and there are many process blowers 2 distributed along the length direction of the air supply main pipe 1, and each process blower inlet is equipped with a waste gas suction pipe 3 respectively. All the exhaust gas suction pipes 3 are connected together through the suction box 7, the outlet is provided with a soft joint 4, and a valve 5 is provided on the soft joint 4. The arrangement direction of the trachea 3 is provided with a suction box 7, and the suction box 7 is connected with all exhaust gas suction pipes 3, and a plurality of exhaust gas suction pipes 8 are arranged along the length direction of the suction box 7, and the exhaust gas suction pipes 8 are connected with each exhaust gas discharge pipe. The air cover of the mouth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com