Transmission shaft balancing device of rolling machine

A technology of balancing device and transmission shaft, which is applied to the driving device of metal rolling mill, metal rolling, metal rolling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

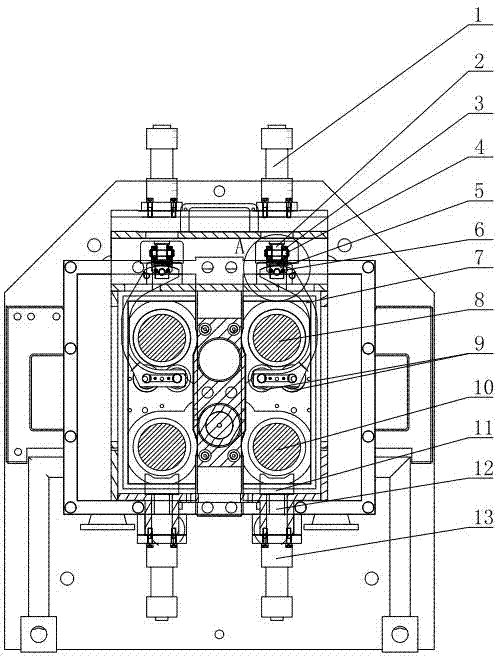

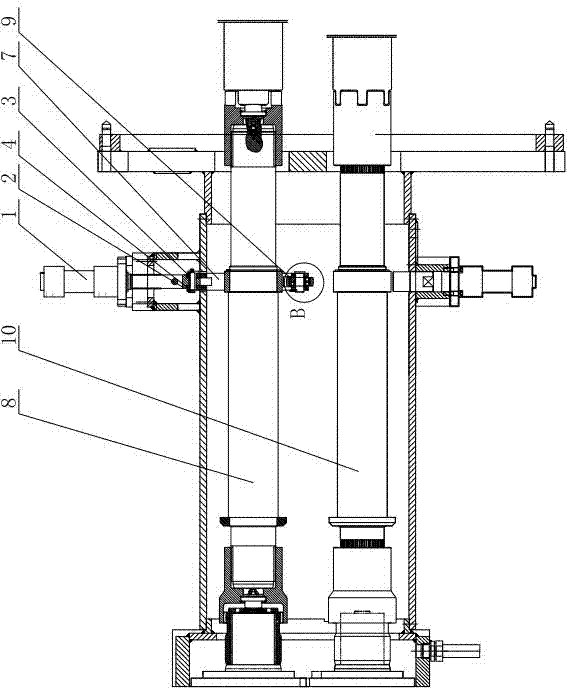

[0026] Such as figure 1 and figure 2 As shown, the rolling mill transmission shaft balancing device of this embodiment includes an upper transmission shaft 8 and a lower transmission shaft 10 installed in the frame, the two ends of the upper transmission shaft 8 and the lower transmission shaft 10 are respectively supported by bearing devices, and the upper transmission shaft A first balance device is installed at the fulcrum of 8, and a second balance device is installed at the fulcrum of the lower transmission shaft 10;

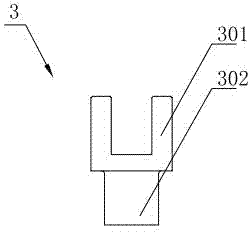

[0027] The structure of the first balance device is as follows: it includes the first oil cylinder 1 installed on the upper part of the upper transmission shaft 8, and also includes the lifting ring 7 cooperating with the upper transmission shaft 8, and the head of the lifting ring 7 is connected to the first oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com