Stamping mould drawing mechanism

A technology of stamping dies and pressing plates, which is applied in the field of multi-station metal molds, can solve problems such as long up and down movement strokes, rapid processing of difficult dies, and failure of drawing materials, and achieves the advantages of facilitating high-speed operations, improving production efficiency, and fast operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

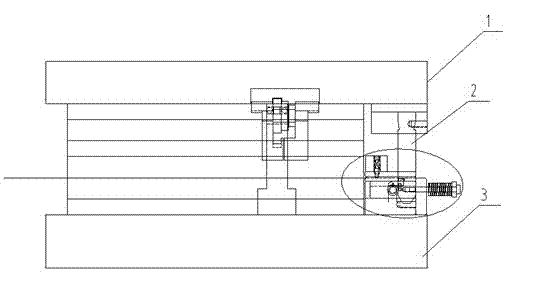

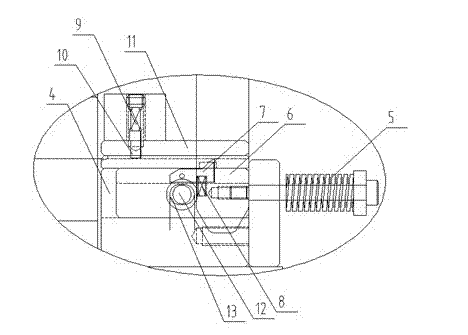

[0013] Embodiment: A material pulling mechanism for a stamping die, comprising an insertion knife 2 fixed on an upper die 1, a concave pulling groove 4 located on a lower die 3, a pulling elastic member 5, a pulling slider 6, a pulling Material block 7, material pulling floating elastic part 8, anti-retraction elastic part 9, anti-retraction block 10 and pressure plate 11, the insertion knife 2 is fixed below the upper die 1, and the material pulling slider 6 can move along the material belt The linear sliding in the conveying direction is located in the pulling groove 4 of the lower die 3. The two ends of the pulling elastic member 5 are fixedly connected with the lower die 3 and the pulling slider 6 respectively. The lower end of the inserting knife 2 is inclined. It can extend into the pulling groove 4 and push the pulling slider 6 to move in reverse along the belt conveying direction. One end of the pulling block 7 along the feeding direction of the material belt is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com