Sleeve support

A sleeve bracket and integrated technology, which is applied to tool storage devices, manufacturing tools and other directions, can solve the problems of difficult portability and storage, disordered sleeve arrangement, inconvenient use, etc., and achieves easy portability, space saving, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

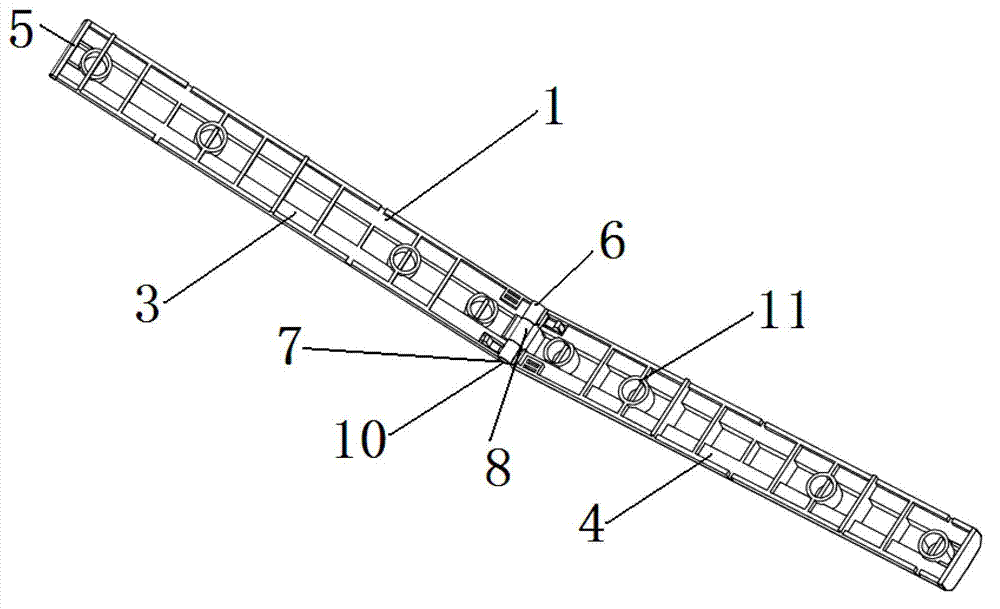

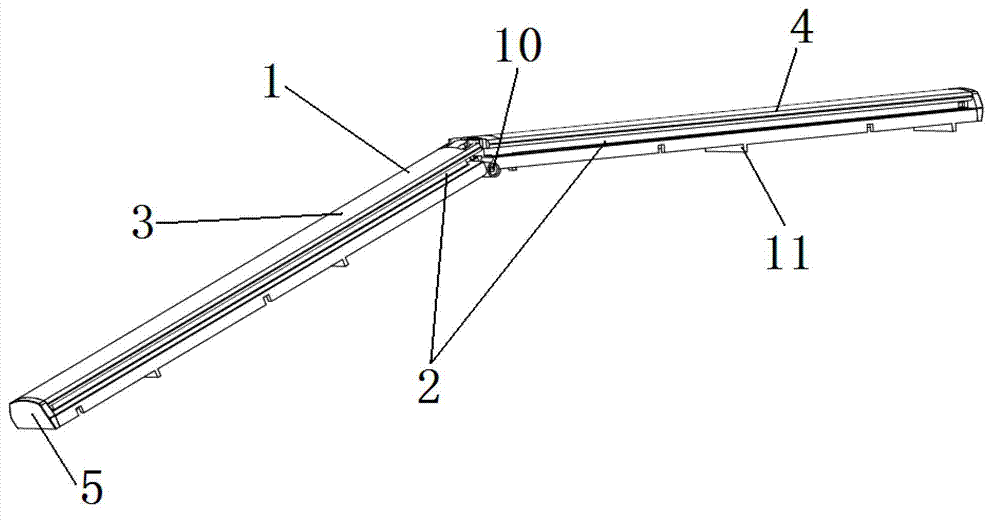

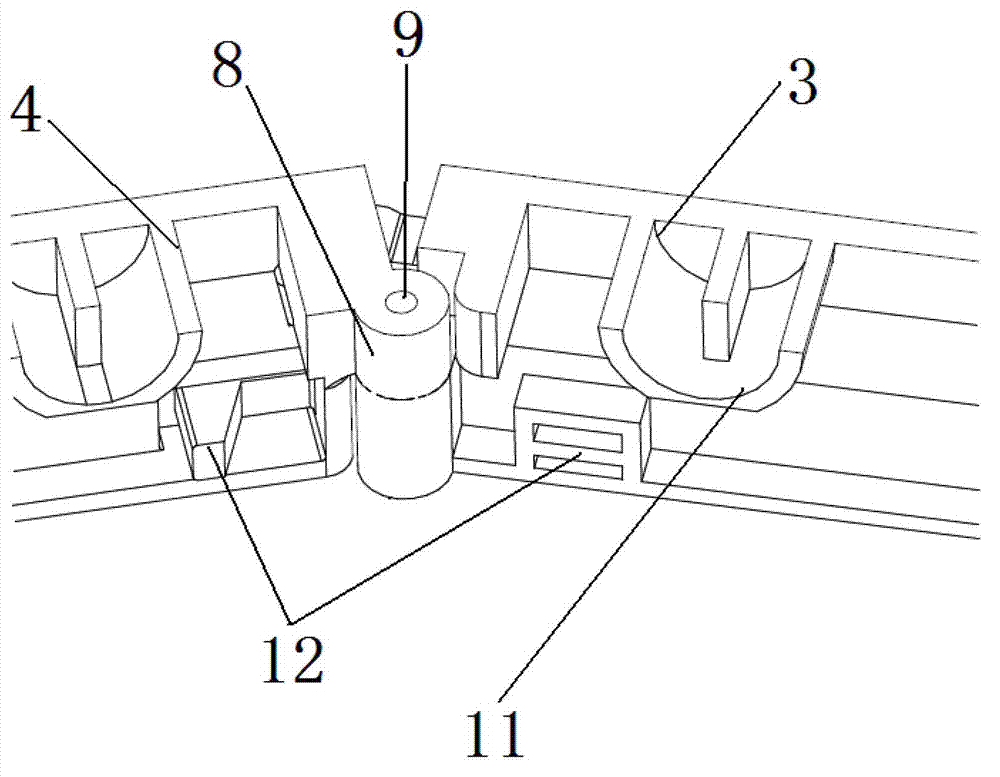

[0026] like Figure 1-3 As shown, a sleeve bracket described in the embodiment of the present invention includes a bracket main body 1, and the two sides of the bracket main body 1 are symmetrically provided with slideways 2, and the slideways 2 are provided with matching sliding blocks. The bracket main body 1 includes The left connecting frame 3 and the right connecting frame 4, the left end of the left connecting frame 3 and the right end of the right connecting frame 4 are provided with stoppers 5, and the stoppers 5 are clamped on the left connecting frame 3 and the right connecting frame 4. At the end, the right end of the left connecting frame 3 is symmetrically provided with a cylindrical boss-6, and the center of the cylindrical boss-6 is coaxially provided with a through hole-7, and the left end of the right connecting frame 4 is provided with a cylinder that cooperates with the cylindrical boss-6. Boss two 8, cylindrical boss two 8 centers are coaxially provided wit...

Embodiment 2

[0029] like Figure 4-6 As shown, a sleeve bracket described in the embodiment of the present invention includes a bracket main body 1, and the two sides of the bracket main body 1 are symmetrically provided with slideways 2, and the slideways 2 are provided with matching sliding blocks. The bracket main body 1 includes The left connecting frame 3 and the right connecting frame 4, the left end of the left connecting frame 3 and the right end of the right connecting frame 4 are provided with stoppers 5, and the stoppers 5 are clamped on the left connecting frame 3 and the right connecting frame 4. At the end, a connection mechanism is arranged in the middle of the left connecting frame 3 and the right connecting frame 4, and several integrally formed reinforcing ribs 11 are provided on the left connecting frame 3 and the right connecting frame 4.

[0030] like Figure 7-8 As shown, the connection mechanism includes an upper cover plate 13, and three claws 15 are arranged equid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com