A device for fixing step-by-step ascending and descending ladders during shipbuilding

A construction process and ladder-dropping technology, which is applied in ship construction, ship parts, transportation and packaging, etc., can solve the problems of inconvenient movement of ladders, injuries of personnel, and low safety of getting on and off ladders, and achieve simple structure, light manufacturing, and Apply handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

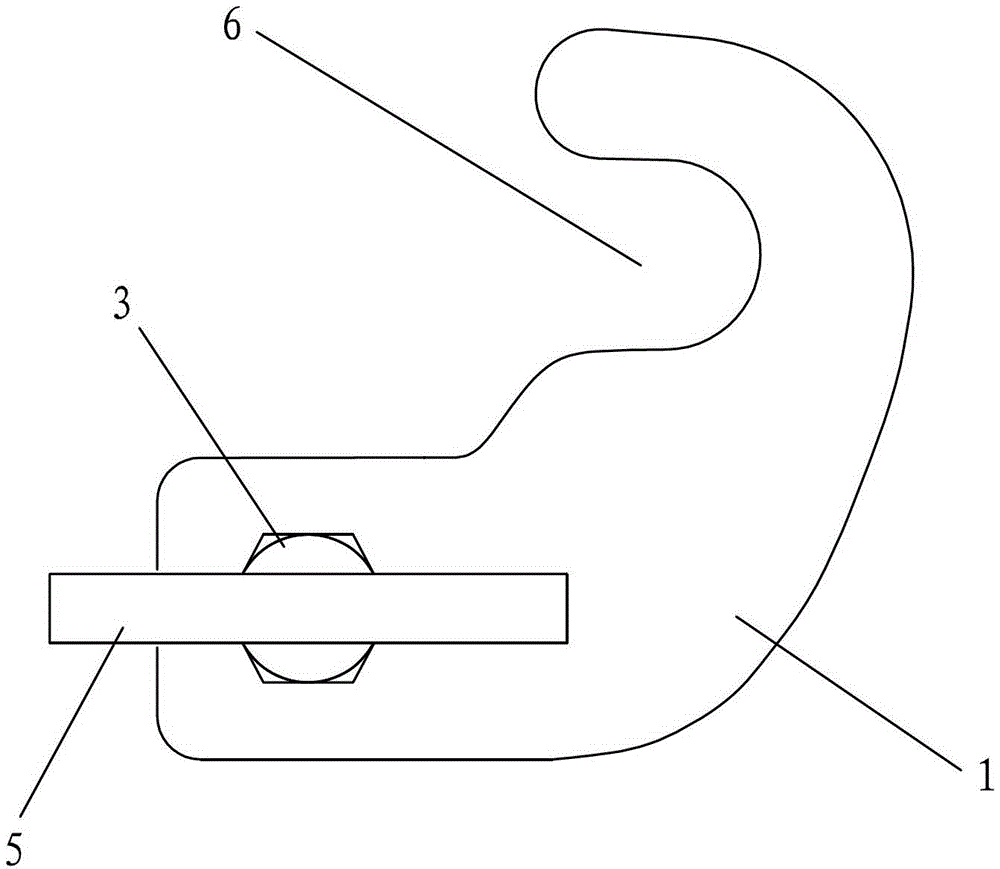

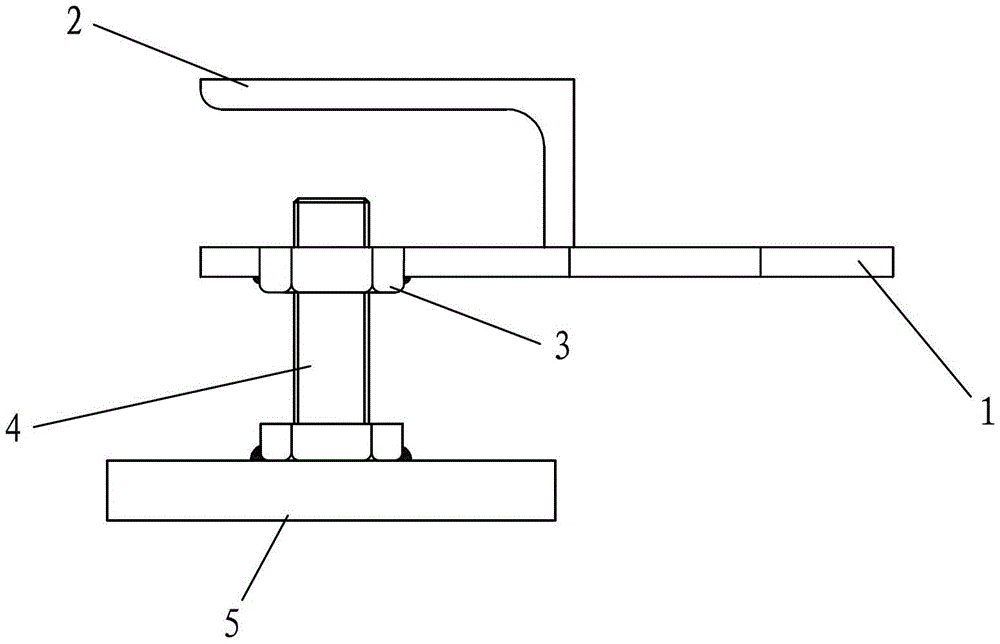

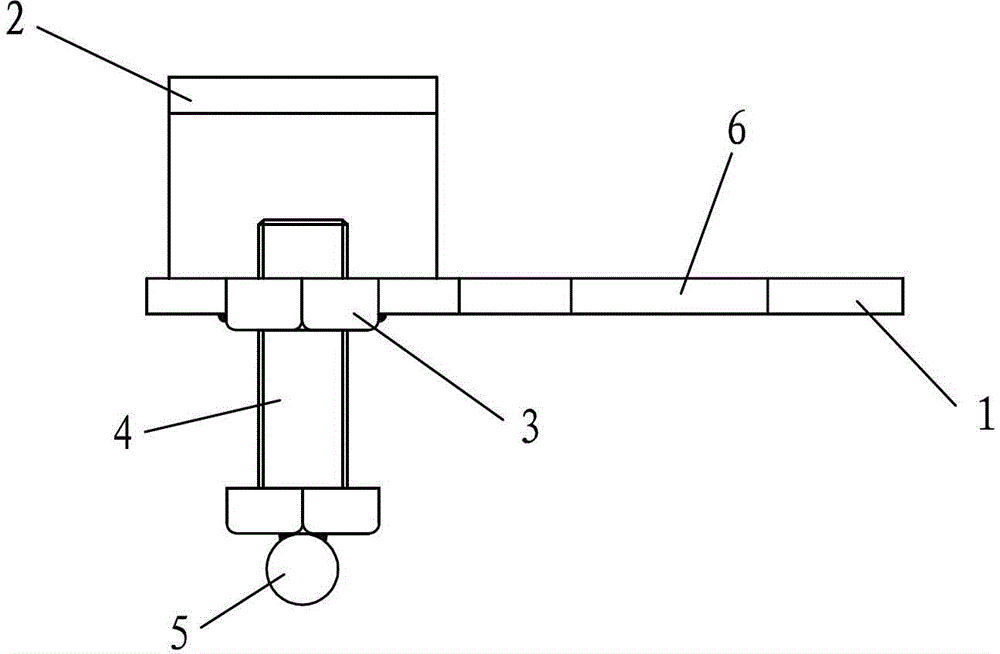

[0012] refer to Figure 1 to Figure 3 , the device provided by the present invention for fixing step-by-step ladders in the ship building process includes a steel or iron hook plate 1, one end of the hook plate 1 is set in the shape of a hook with an opening 6, and the hook plate 1 is provided with The splint 2 and the embedded nut 3, one end of the splint 2 is fixed on the hook plate 1 by welding, the other end of the splint 2 is bent parallel to the hook plate 1 and located above the embedded nut 3, the embedded nut 3 is equipped with a screw 4, The screw rod 4 is used to cooperate with the splint 2 to clamp the plate, and the screw rod 4 is provided with a handle 5 for easy rotation. The use process of this product is: place the ladder on the edge of the ship section stably, set the opening 6 on the top of the hook plate 1 tightly to the vertical steel pipe of the ladder, and at the same time clamp the splint 2 on the panel of the ship section. After the adjustment and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com