Aluminum alloy composite and engine cover plate made of same

A technology of engine cover and composite materials, which is applied in the field of aluminum alloy composite materials, can solve the problems of poor shockproof and noise-proof effects, and achieve superior shock-absorbing and noise-reducing performance and obvious effects of shock-reducing and noise-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

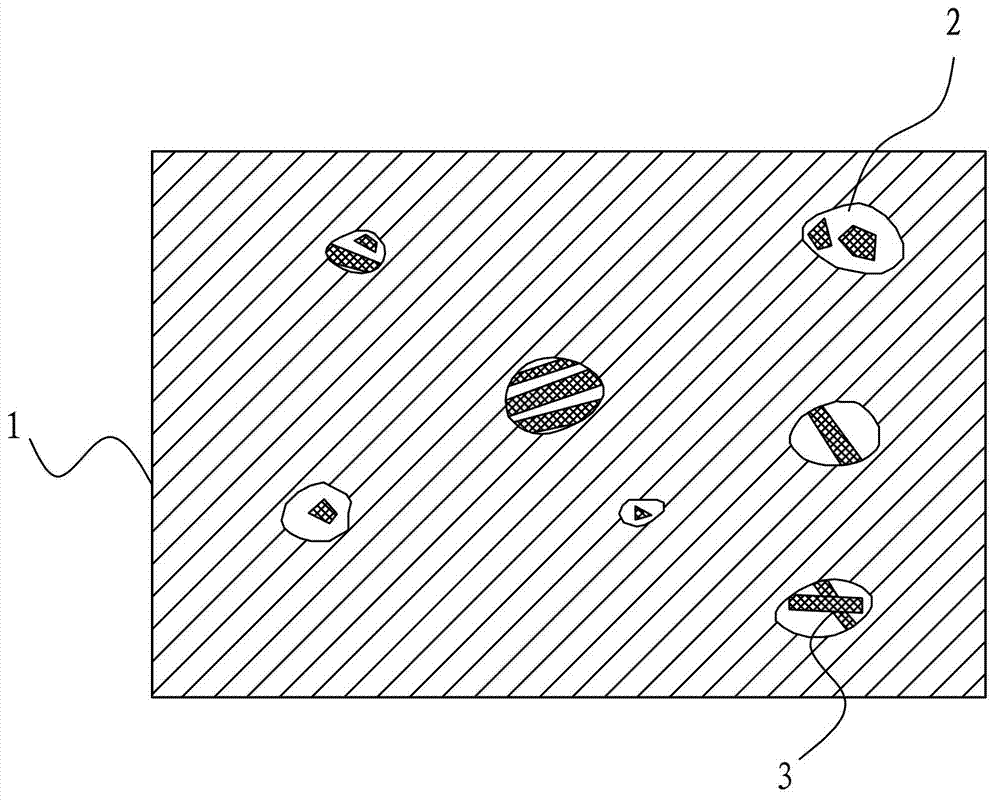

[0018] refer to figure 1 , the present invention will be further described below in conjunction with accompanying drawing and embodiment.

[0019] In the aluminum alloy composite material of the present invention, discontinuous closed holes 2 are evenly distributed inside the aluminum alloy matrix 1, the diameter of the holes 2 is less than 3.5mm, and there are one or more refractory fibers 3 in the holes 2, and the refractory fibers 3 are preferably Aluminum silicate fibers or graphite fibers that are resistant to high temperatures and incompatible with aluminum alloys can be in the form of strips or particles; due to the shape relationship of the refractory fibers 3, the two ends of the refractory fibers 3 It is connected to the inner wall of the hole 2, or one end of the refractory fiber 3 is connected to the inner wall of the hole 2, and the other end is suspended in the hole 2.

[0020] The production process of the aluminum alloy composite material of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com