Comprehensive frictional resistance meter

A friction resistance and stress meter technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve problems such as easy failure and influence on measurement accuracy, and achieve the effect of strong applicability, high precision, and high test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

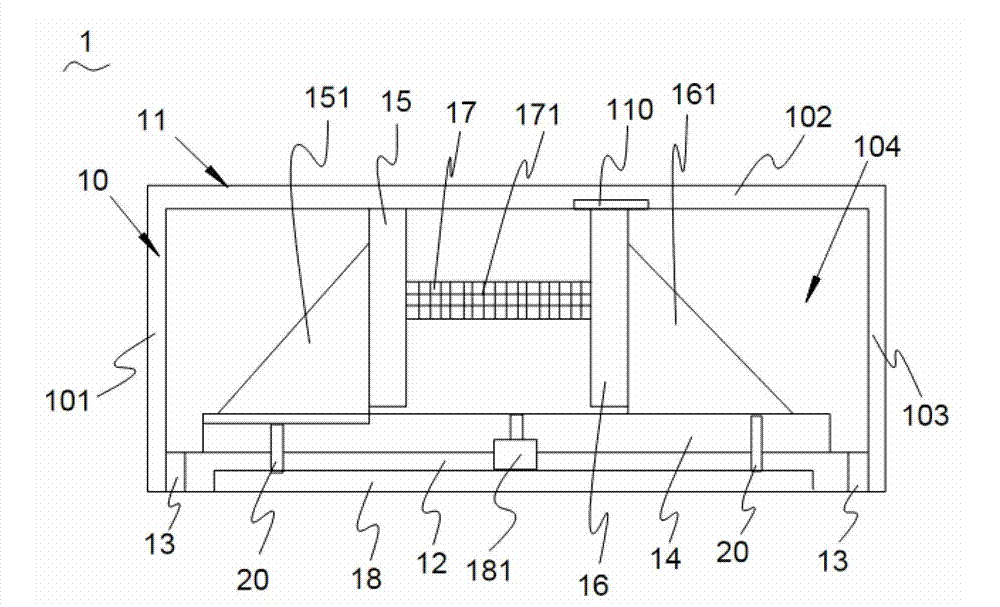

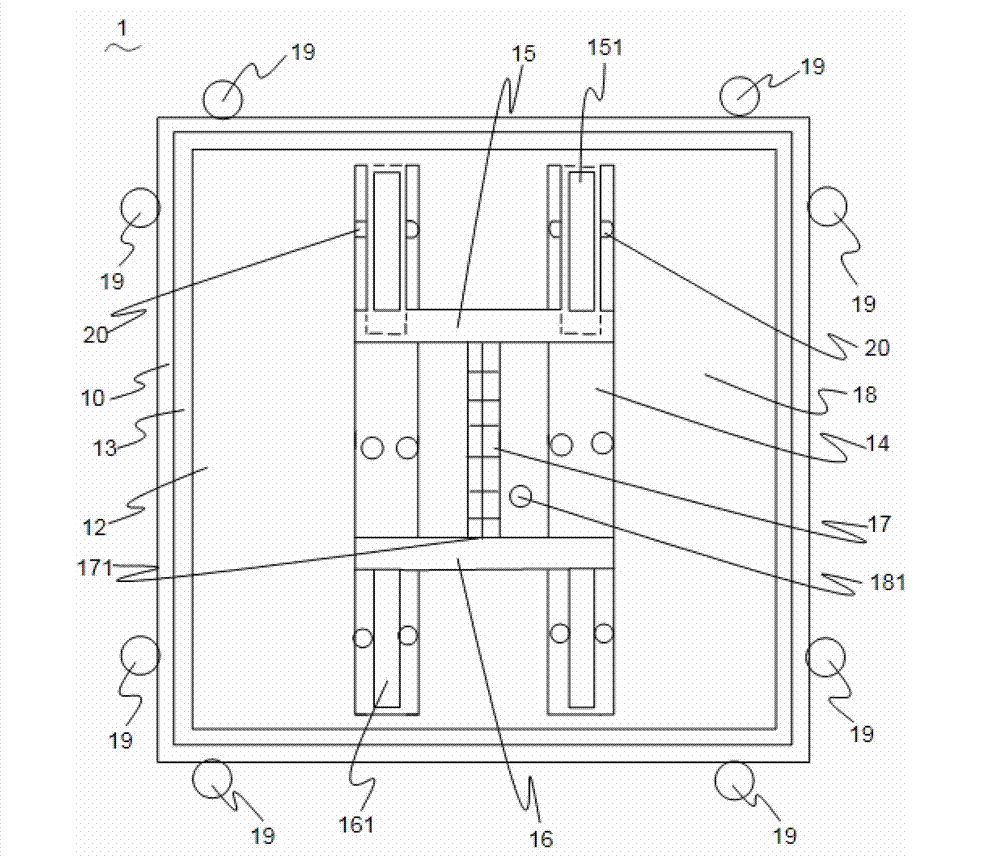

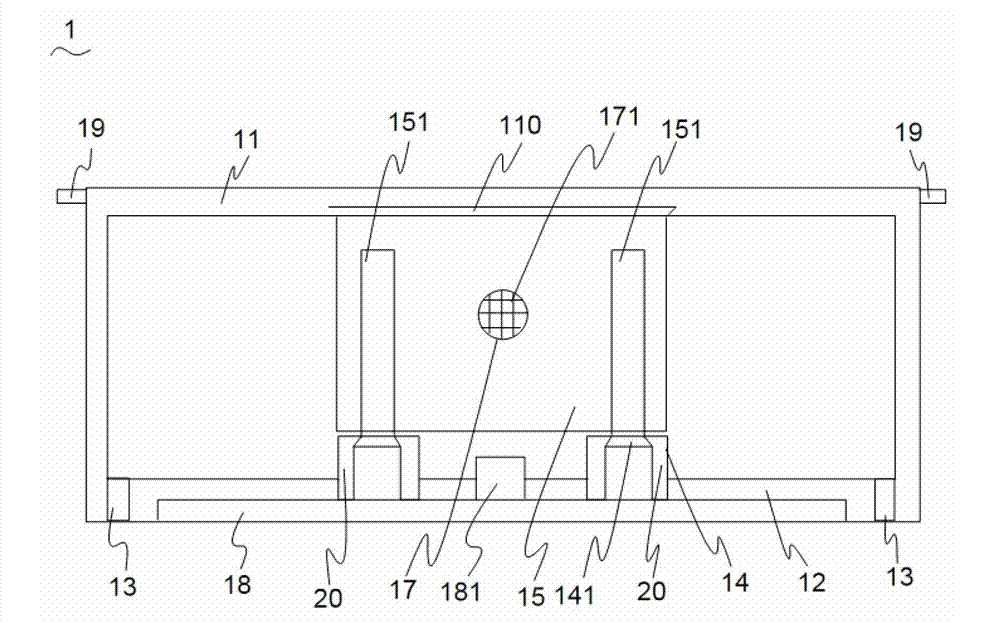

[0025] see figure 1 , figure 2 , figure 1 Shown is a side view structure schematic diagram of the comprehensive friction resistance meter of the present invention. figure 2 Shown is a top view structure schematic diagram of the comprehensive friction resistance meter of the present invention. The comprehensive friction meter 1 includes a protective box 10, and the protective box 10 has a receiving space 104 enclosed by a first baffle plate 101, a second baffle plate 102, and a third baffle plate 103 connected in sequence; a fixed panel 11, has a fixed panel sliding slot 110, and is formed at the second baffle plate 102 of the protective box 10; a force-bearing panel 12, the force-bearing panel 12 is set facing the fixed panel 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com