Tapered jet foam sol generating device for controlling coal dust at transferring point of conveyor belt

A transfer point and conveyor belt technology, which is applied in the field of coal mines, can solve the problems of lack of industrial tests and practical applications, and the inability to realize continuous work, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

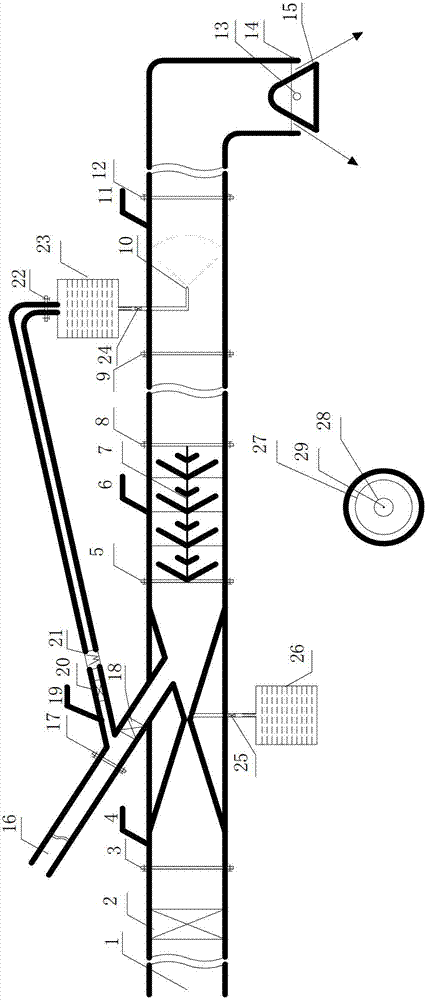

[0023] Such as figure 1 As shown, the conical jet foam sol generating device for controlling the transfer point of coal dust on the conveyor belt provided by the present invention mainly consists of three parts: one is a foam generating part; the other is a foam gelling part; the third is a foam sol outlet part.

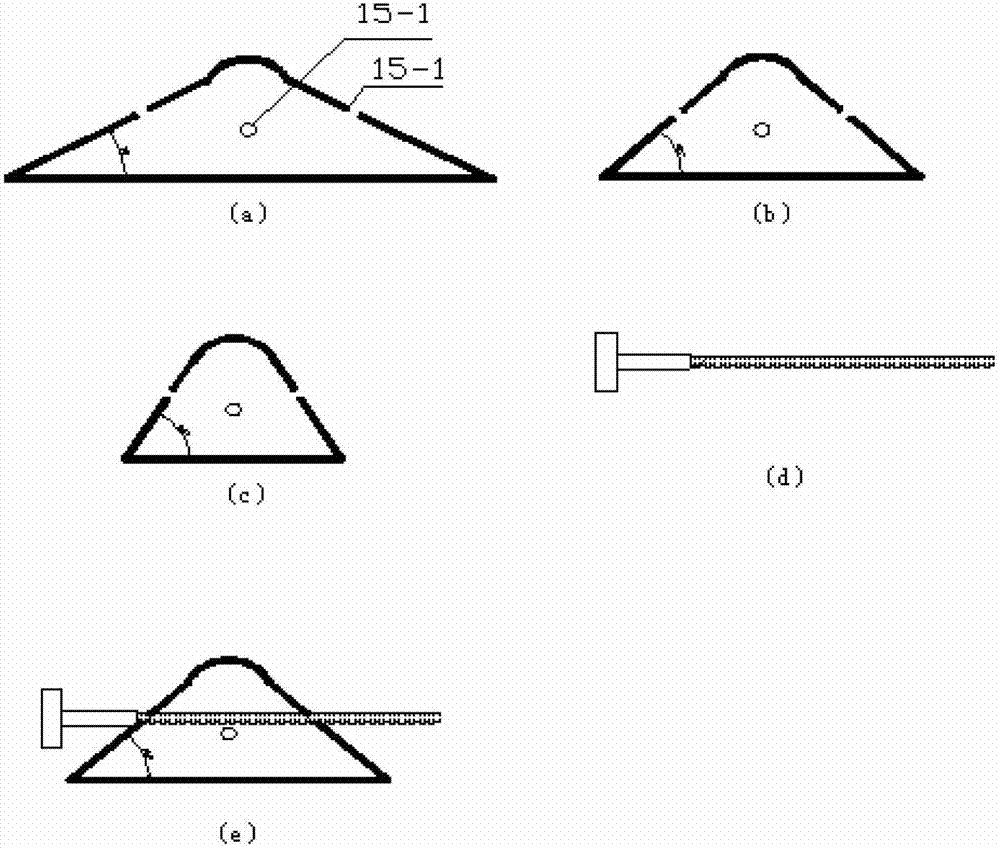

[0024] The conical jet foam sol generating device of the present invention mainly includes: water inlet pipe 1, negative pressure adder 4, surfactant solution packer 26, mixer 6, stirring baffle 7, gelling device 11, adhesive packer 23, nozzle 10, intake pipe 16, diffuser 15, air distribution pipe 19.

[0025]The inlet of the negative pressure adder 4 is connected to the water inlet pipe 1 through the regulating valve 2 and the connecting valve 3, the outlet is connected to the inlet of the mixer 6 through the connecting valve 5, and the throat of the negative pressure adding device is connected to the surfactant through the regulating valve 25. The solution packer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com