Oil change system of wind driven generator gearbox and leak-proof security protection method for oil chang

A technology for wind turbines and gearboxes, applied in the directions of gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc., can solve the problems of oil pollution of the marine environment, high cleaning costs, bursting and shedding, etc. The effect of reducing losses and possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

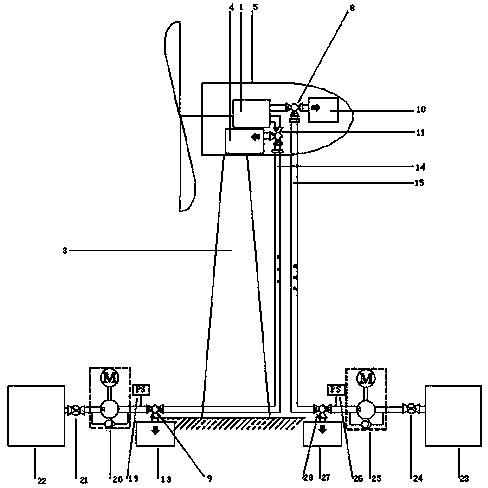

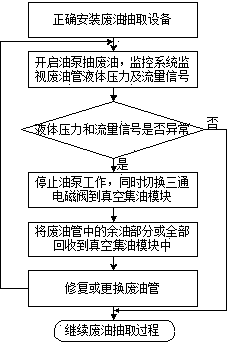

[0031] see figure 1 with figure 2 , a wind power generator gearbox oil change system, including a waste oil extraction system and a new oil filling system, the waste oil extraction system includes a waste oil pipe 14, a waste oil delivery pump 20 and a waste oil tank 22, and the waste oil delivery pump 20 passes through the waste oil The oil pipe 14 transports the waste lubricating oil in the gear box 1 located at the top of the tower tube 3 of the wind power generator to the waste oil tank 22. The new oil filling system includes a new oil pipe 15, a new oil delivery pump 25 and a new oil tank 23. The delivery pump 25 injects the new oil in the new oil tank 23 into the gear box 1 through the new oil pipe 15, and it is characterized in that a waste oil leakage prevention safety protection device is provided along the waste oil pipe 14, that is, it is close to the gear box 1 A three-way solenoid valve I11 is installed in series on the high-altitude initial section of the waste...

Embodiment 2

[0038] The technical solution of this embodiment is basically the same as that of Embodiment 1, especially in that:

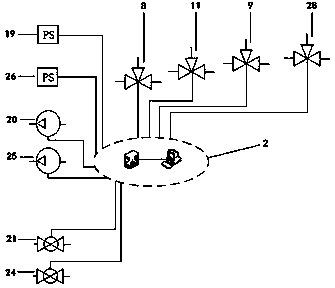

[0039] In this example, see Figure 5 with Image 6 , the three-way solenoid valve I11 and the three-way solenoid valve III8 carry out data transmission with the central control unit 2 through wireless communication equipment, specifically, the command signal output end of the central control unit 2 is connected to the wireless signal sending device 18, and the three-way solenoid valve I11 The signal receiving end is connected to the wireless signal receiving device 12 , and the signal receiving end of the three-way solenoid valve III 8 is connected to another wireless signal receiving device 7 . For the wind turbine gearbox oil change system of this embodiment, which is installed in high-altitude electronic component equipment, the use of wireless signal transmission is safer and more reliable than wired link transmission. In addition to ensuring the stabilit...

Embodiment 3

[0041] The technical solutions of this embodiment are basically the same as those of the foregoing embodiments, and the special features are:

[0042] In this example, see Figure 7 , the waste oil extraction system and the new oil filling system are also provided with a safety enhanced auxiliary protection mechanism, the safety enhanced auxiliary protection mechanism is composed of a steel cable 16 and a plurality of flexible stable rings 17, the top of the steel cable 16 is connected to the steel cable fixing pile 6, The cable fixed pile 6 is fixedly connected to the top of the tower tube 3 of the wind-driven generator, and the bottom end of the steel cable 16 is connected to the ground pile 29, and the ground pile 29 is fixedly connected to the bottom foundation of the tower tube 3 of the wind-driven generator, so that the steel cable 16 Set from top to bottom, and be stretched and straightened, each flexible stable ring 17 has one end to cover the waste oil pipe 14 or new ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com