Dry-type slag conveying device, slag removing apparatus, and slag removing method

A kind of slag discharge equipment and slag conveying technology, which is applied in the direction of lighting and heating equipment, etc., can solve the problem of low efficiency of ash discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

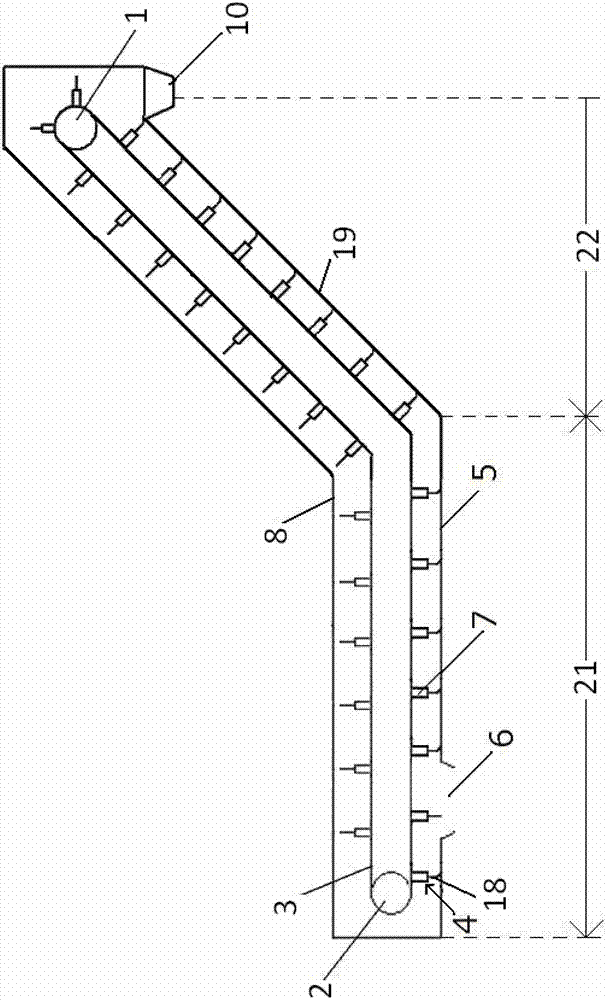

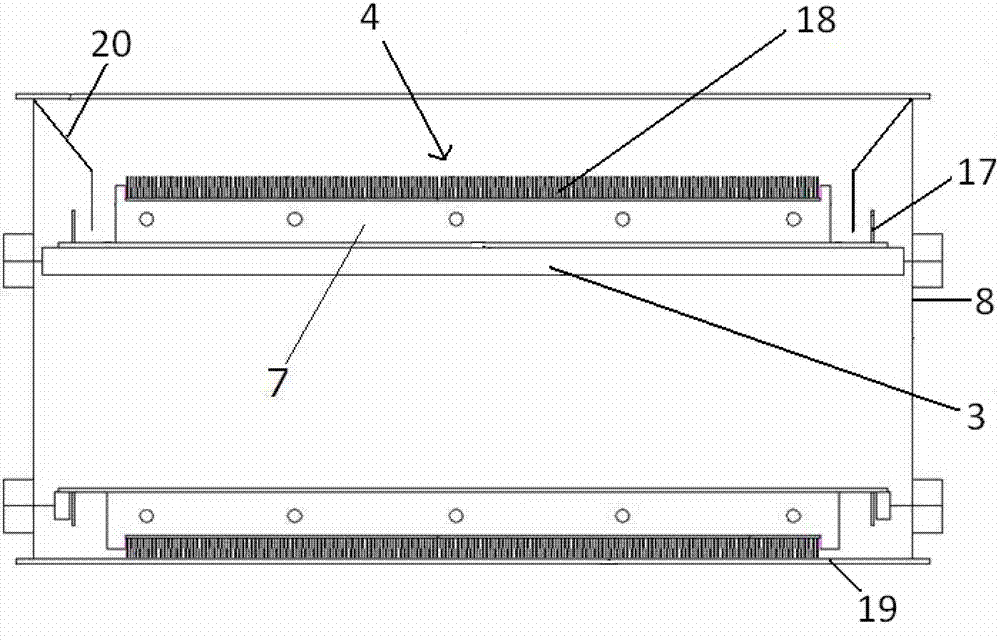

[0070] Such as figure 1 A dry slag conveying device of this embodiment is shown, wherein the dry slag conveying device is arranged inside the box body 8 of the slag discharge equipment, and is used to cooperate with the box body 8, wherein the The box body 8 of the slagging equipment includes a box body collection section 21 arranged below the boiler slag discharge port 9, and a box body delivery section 22 connected to the box body collection section 21 at one end, and the box body delivery section 22 The other end has a slag outlet 10 located at a high position. The angle between the bottom bearing surface 19 of the box body and the horizontal plane of the box body conveying section 22 is smaller than the angle of repose of fine ash. In this embodiment, the box body of the box body conveying section 22 The angle between the bearing surface 19 at the bottom of the body and the horizontal plane is 35 degrees.

[0071] The dry slag conveying device includes a first roller devi...

Embodiment 2

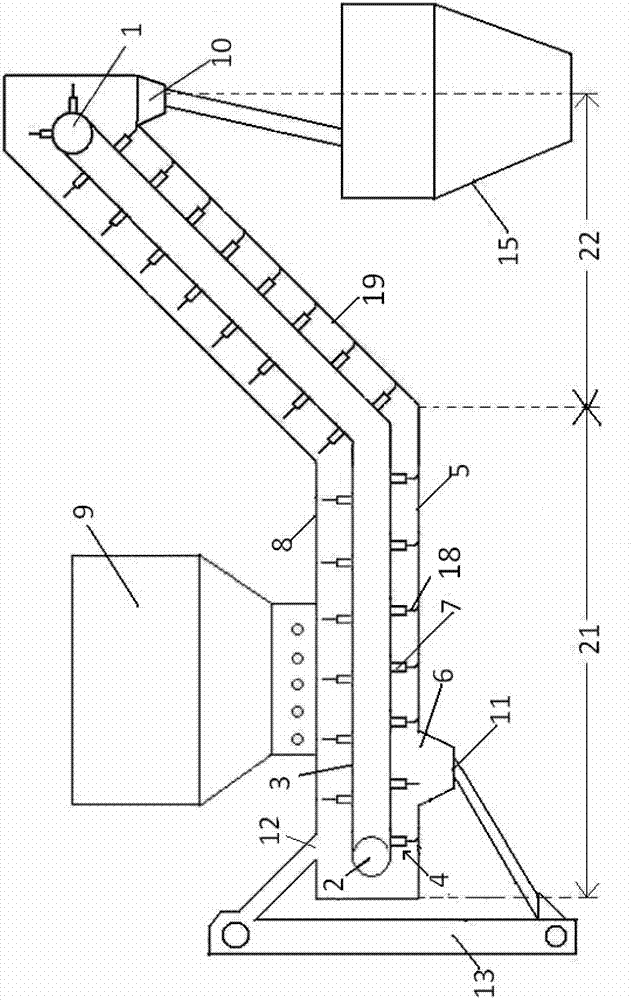

[0075] Such as image 3 It is a schematic diagram of a slagging equipment, which includes a box 8, the box 8 includes a box collection section 21 arranged below the boiler slag outlet 9, and one end is connected to the box collection section 21 The connected box conveying section 22, the other end of the box conveying section 22 has a slag outlet 10, and the box collecting section 21 is formed on the bottom bearing surface 19 of the box away from the box conveying section 22. The fine ash outlet 6, the included angle between the box bottom bearing surface 19 of the box conveying section 22 and the horizontal plane is smaller than the fine ash repose angle, and the included angle in this embodiment is 30 degrees.

[0076] Wherein, the slag conveying device is installed inside the box body 8, including a first roller device 1, a second roller device 2, and a conveyor belt 3; wherein, the first roller device 1 and the second roller device 2 are respectively It is arranged at bot...

Embodiment 3

[0084] As another alternative embodiment of the slagging equipment of the present invention, such as Figure 4 As shown, a box body 8 is included, and the box body 8 includes a box body collection section 21 arranged below the boiler slag outlet 9, and a box body conveying section 22 connected to the box body collection section 21 at one end, the box body The other end of the body conveying section 22 has a slag discharge port 10 located at a high position, and a fine ash outlet 6 is formed on the bottom bearing surface 5 of the box body at the end of the box body collecting section 21 away from the box body conveying section 22, and the box body collection section 21 is formed with a fine ash outlet 6. The included angle between the bearing surface 19 of the box bottom of the body conveying section 22 and the horizontal plane is smaller than the angle of repose of the fine ash, and the included angle in this embodiment is 25 degrees.

[0085] The above-mentioned slagging equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com