Automatic ultrasonic detection system of non-contact solid geologic model

A geological model and automatic detection technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, geophysical measurements, seismology, etc., can solve the problems that the signal cannot reach the deep layer of the model, the ultrasonic emission energy is not enough, and the excitation effect is affected. The simulation effect is realistic, the automatic detection is good, and the acquisition speed is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, the present invention is described in further detail:

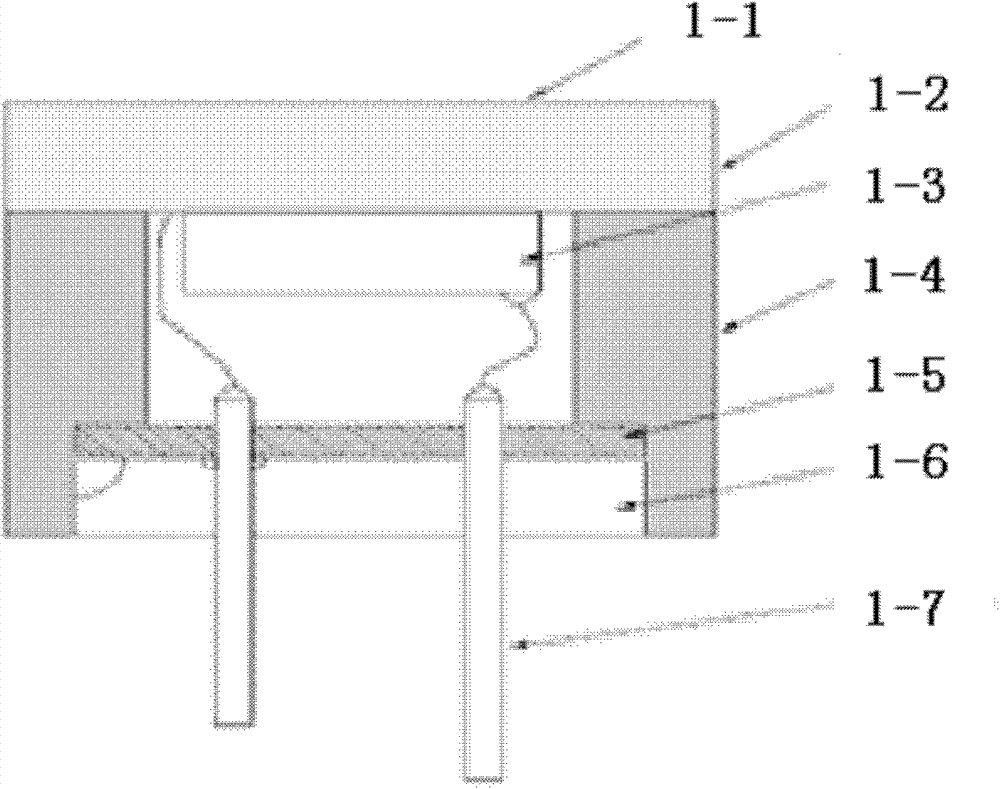

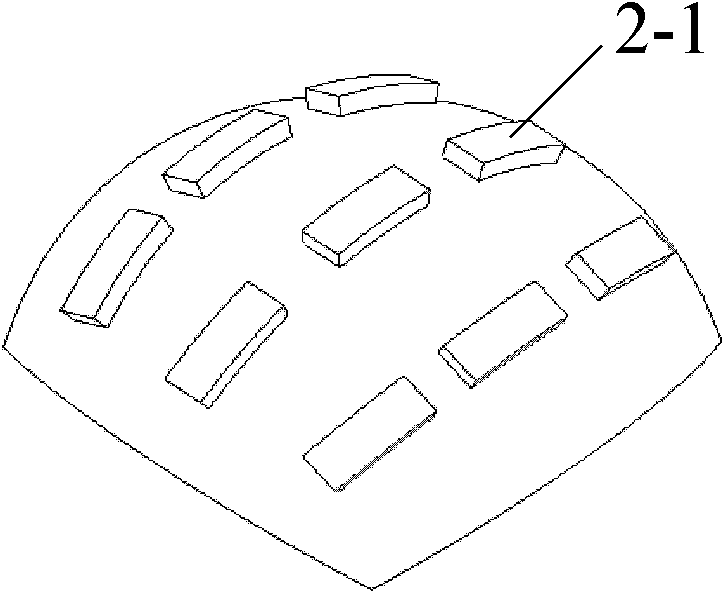

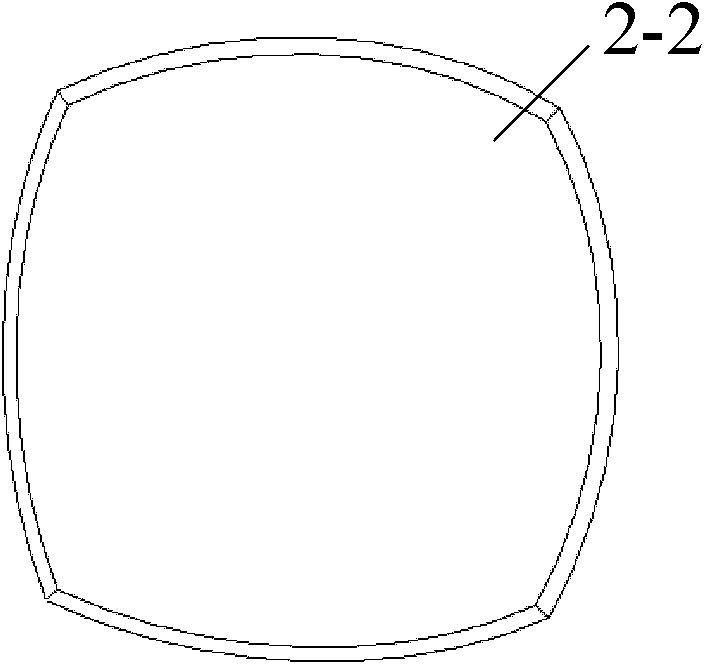

[0048] A non-contact solid geological model ultrasonic automatic detection system, including a transmitting device, a receiving device, a high-speed analog-to-digital converter and a three-dimensional coordinate instrument platform; the measured geological model, the transmitting device and the receiving device are all installed on the three-dimensional coordinate instrument On the platform; the high-speed digital-to-analog converter processes the signal collected by the receiving device, and then transmits it to the computer.

[0049]The transmitting device includes a high-voltage pulse generator and a non-contact focusing probe. When testing the geological model to be tested, the mechanical device (referring to the mechanical fixture where the laser head or the transmitting probe is installed and moved by the mechanical screw) reaches the detection point and sends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com