Patents

Literature

37 results about "Coordinatograph" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coordinatograph is an instrument which mechanically plots X and Y coordinates onto a surface, such as in compiling maps or in plotting control points such as in electronic circuit design. One historic application of a coordinatograph was a machine that precisely placed and cut rubylith to create photomasks for early integrated circuits including some of the earliest generations of the modern PC microprocessor. The coordinatograph produced layout would then be photographically reduced 100:1 to create the production photomask.

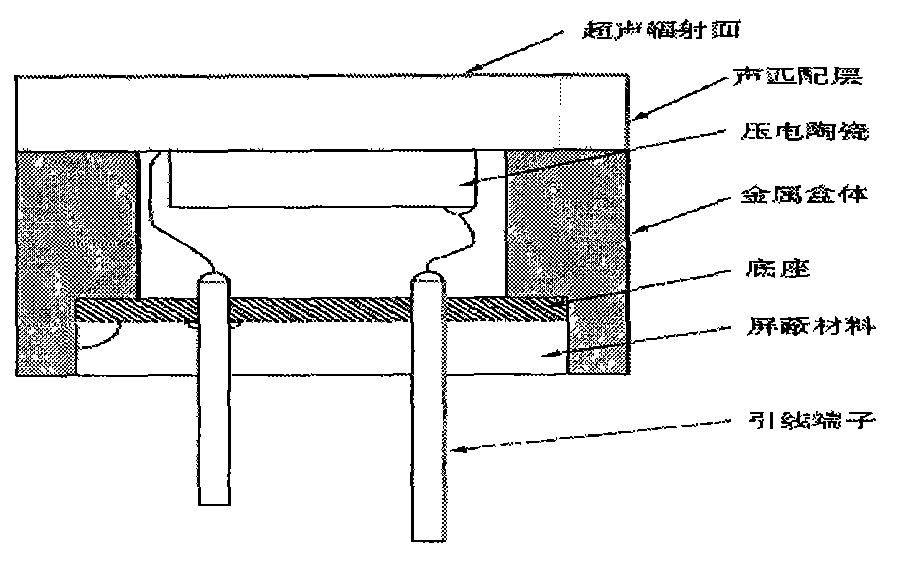

Automatic ultrasonic detection system of non-contact solid geologic model

ActiveCN102818841ASmall launch pointSmall receiving pointAnalysing solids using sonic/ultrasonic/infrasonic wavesSeismologyHigh voltage pulseCoordinatograph

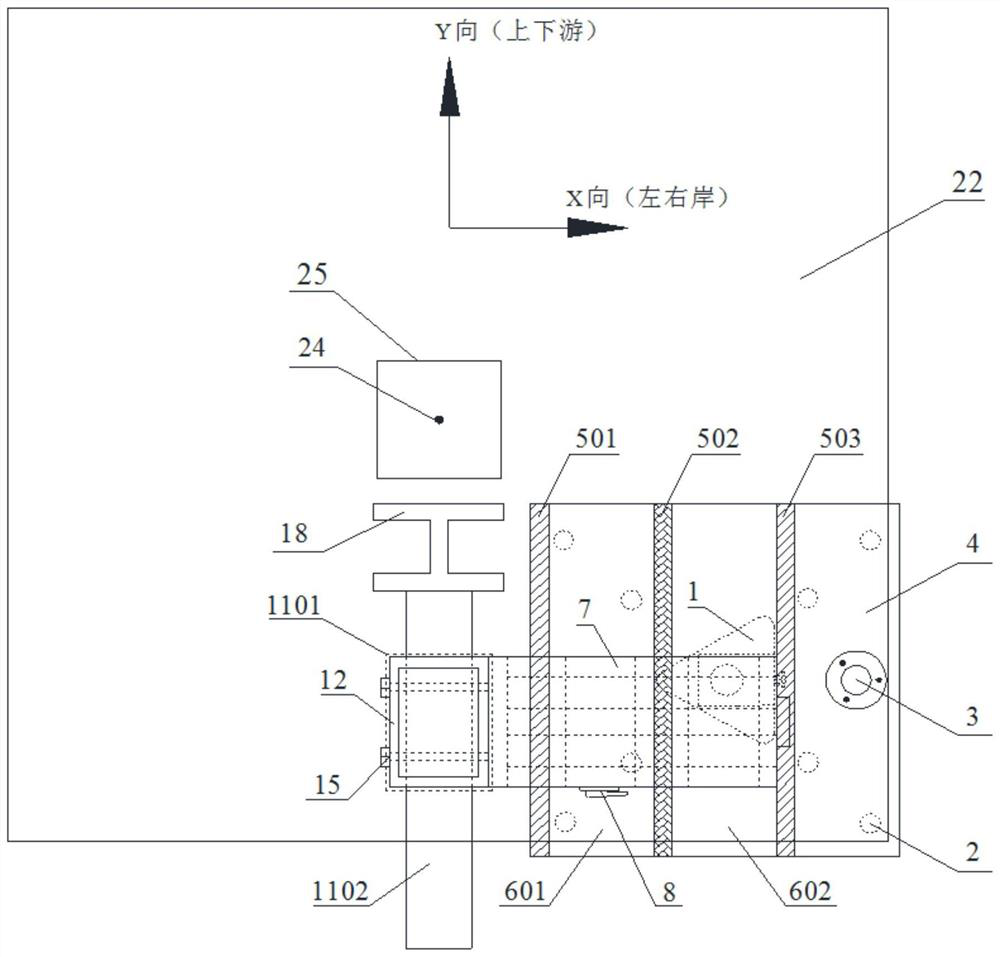

The invention provides an automatic ultrasonic detection system of a non-contact solid geologic model and belongs to the field of ultrasonic vibrating detection. The automatic ultrasonic detection system comprises an emitting device, a receiving device, a high-speed analog-to-digital converter and a three-dimensional coordinatograph platform. A detected geologic model, the emitting device and the receiving device are all arranged on the three-dimensional coordinatograph platform. The high-speed analog-to-digital converter processes signals collected by the receiving device and then transmits the signals to a computer. The emitting device comprises a high-voltage pulse generator and a non-contact focusing probe. The automatic ultrasonic detection system solves the problem of various normal geologic model simulation systems, can perform large-scale multipoint non-contact ultrasonic detection for complex surface models and meets special requirements of modern geophysical prospecting fine simulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Curved weld joint tracking method based on weld joint industrial robot postures

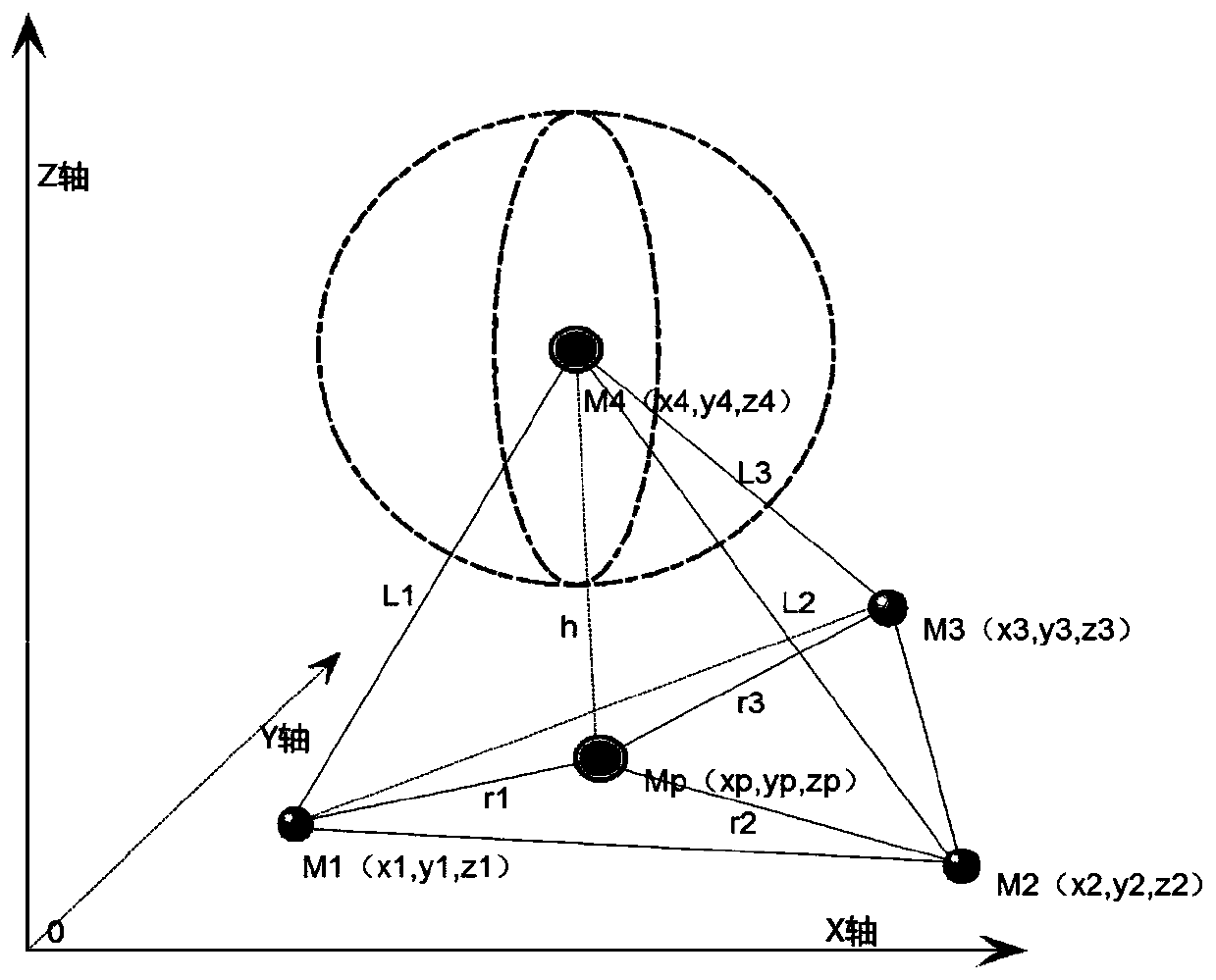

The invention discloses a curved weld joint tracking method based on weld joint industrial robot postures. The curved weld joint tracking method comprises the steps that boundary points of a weld joint portion are selected to build a space coordinates system for the X axis, the Y axis and the Z axis, the position of a weld joint point is represented through the space coordinates system, connectinglines among points in the weld joint position are curved lines, connecting tracks among the points are calculated through a space curve formula, and weld joint tracks of the curved lines are determined. According to the curved weld joint tracking method based on the weld joint industrial robot postures, through combination of a feature recognition camera and a measuring sensor, weld joint featurepictures extracted from a robot are subjected to coordinatograph, the weld joint shapes of the curved lines are represented with points in the space, and then a welding gun is controlled to sequentially weld the points; meanwhile, by eliminating position differences of a body, errors of the weld joint position are avoided, and the weld joint precision is improved; and the welding gun adopts the form of a bulb base, moving in the space is convenient, the welding precision is higher, the welding position is more flexible, the welding position is determined through testing data, the automation degree is higher, and operation is convenient.

Owner:苏州佩恩机器人有限公司

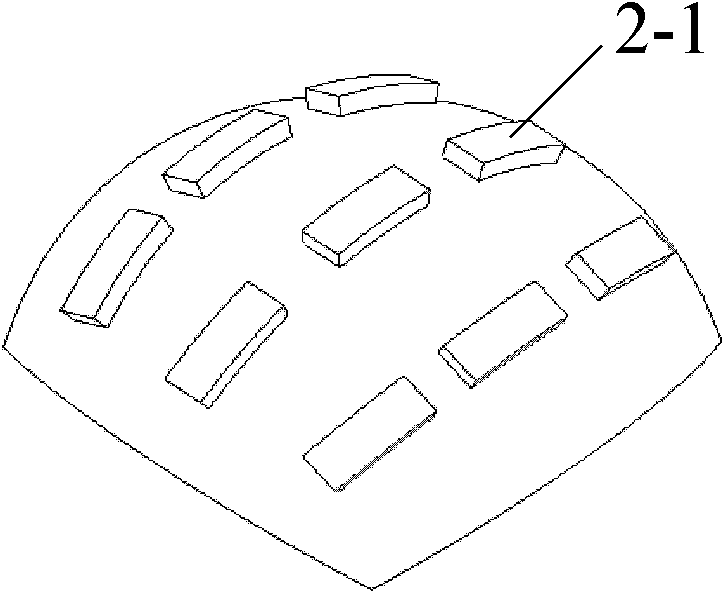

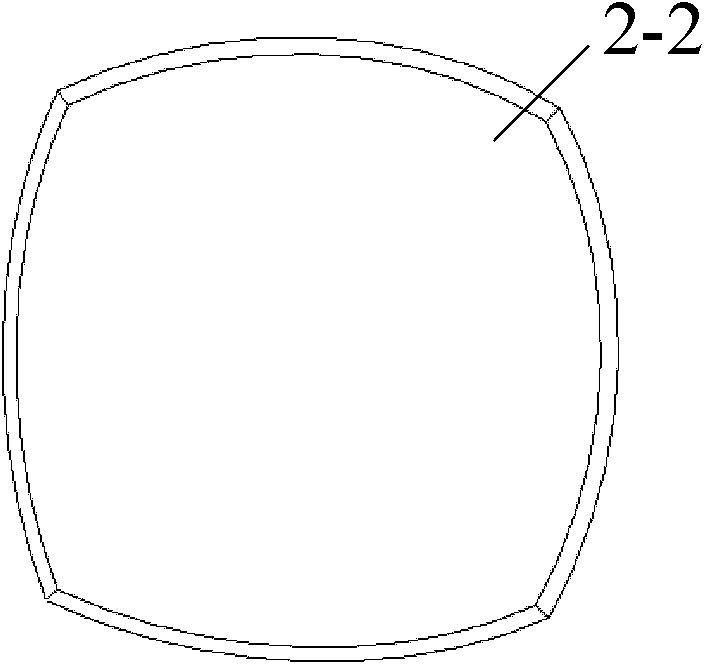

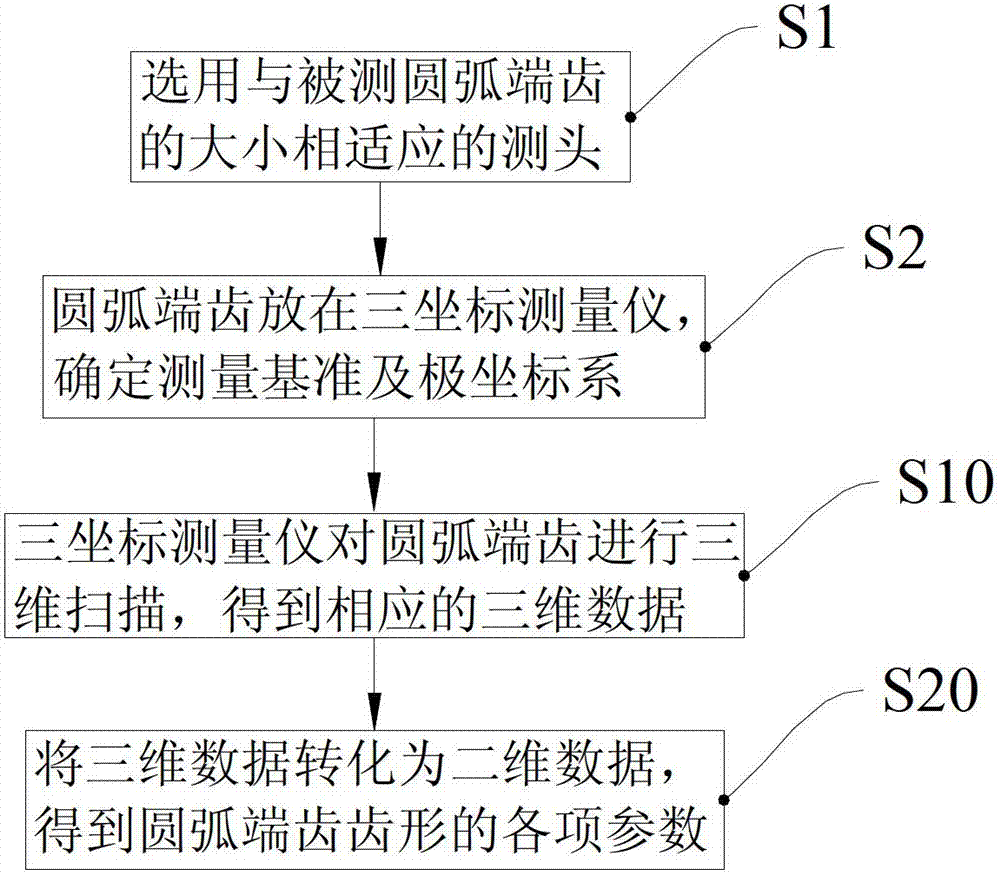

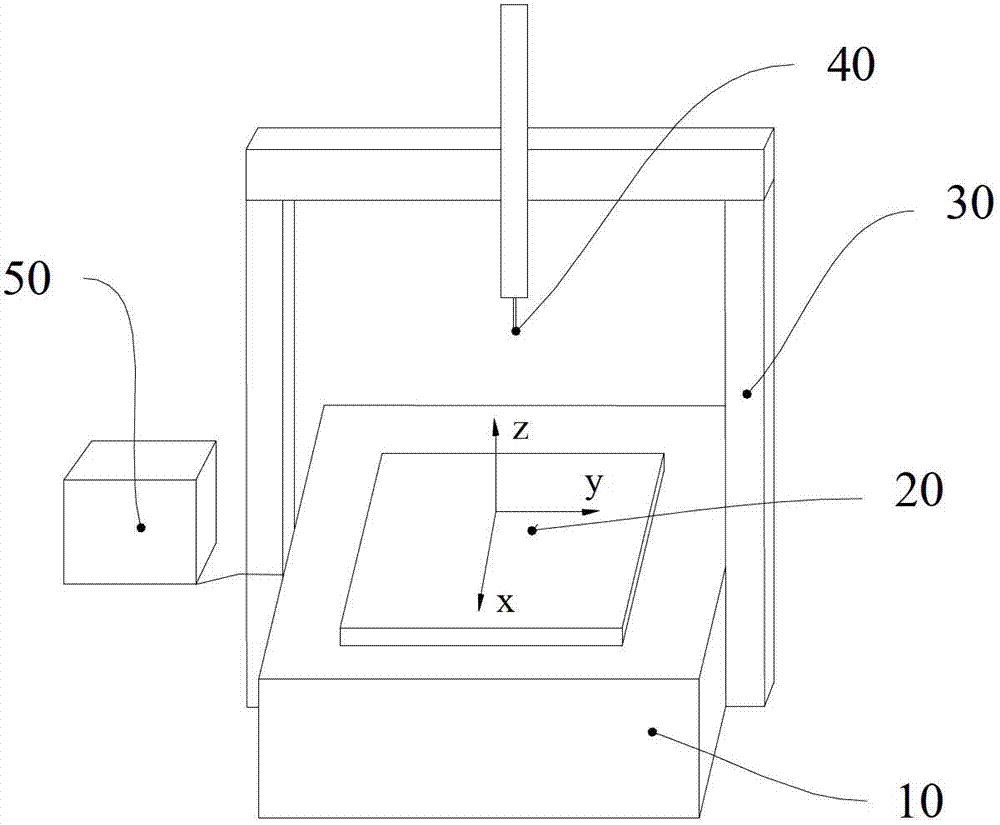

Method for measuring circular arc end tooth

The invention provides a method for measuring a circular arc end tooth, which comprises the following steps of step S10, scanning the periphery of a circular arc end tooth through a three-coordinate measuring instrument in a three-dimensional manner to obtain the corresponding three-dimensional data; and step S20, converting the three-dimensional data into a two-dimensional data to obtain various parameters of a circular arc end tooth shape. The method for measuring the circular arc end tooth measures the circular arc end tooth through the three-coordinate measuring instrument, and the detected three-dimensional data is converted into the two-dimensional data. The method is simpler, and has smaller measurement error, stable measured data and good repeatability; and moreover, the graphic software is utilized to conveniently and directly process the data, and the method is suitable for calibrating various circular arc end tooth gauges and mapping the circular arc end tooth.

Owner:CHINA HANGFA SOUTH IND CO LTD

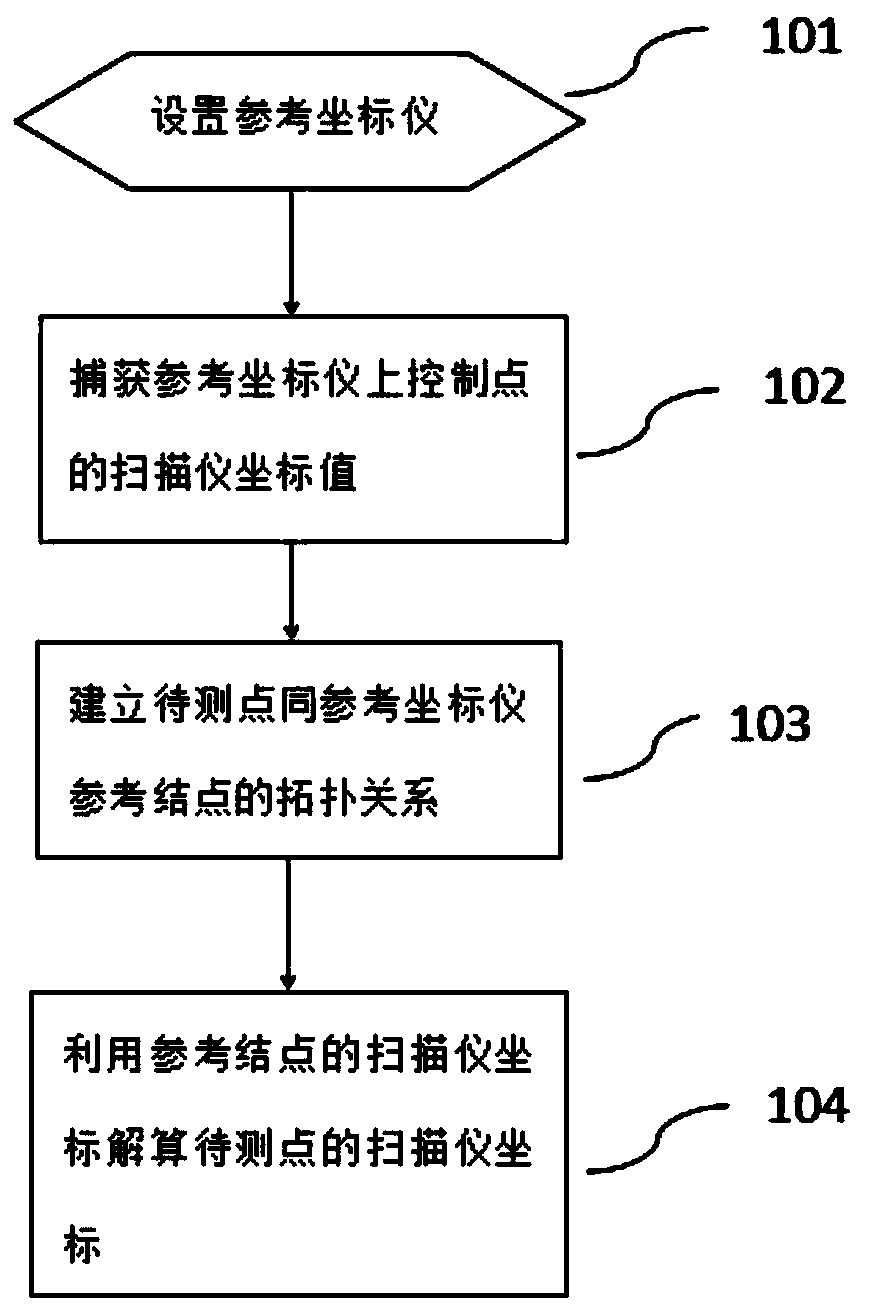

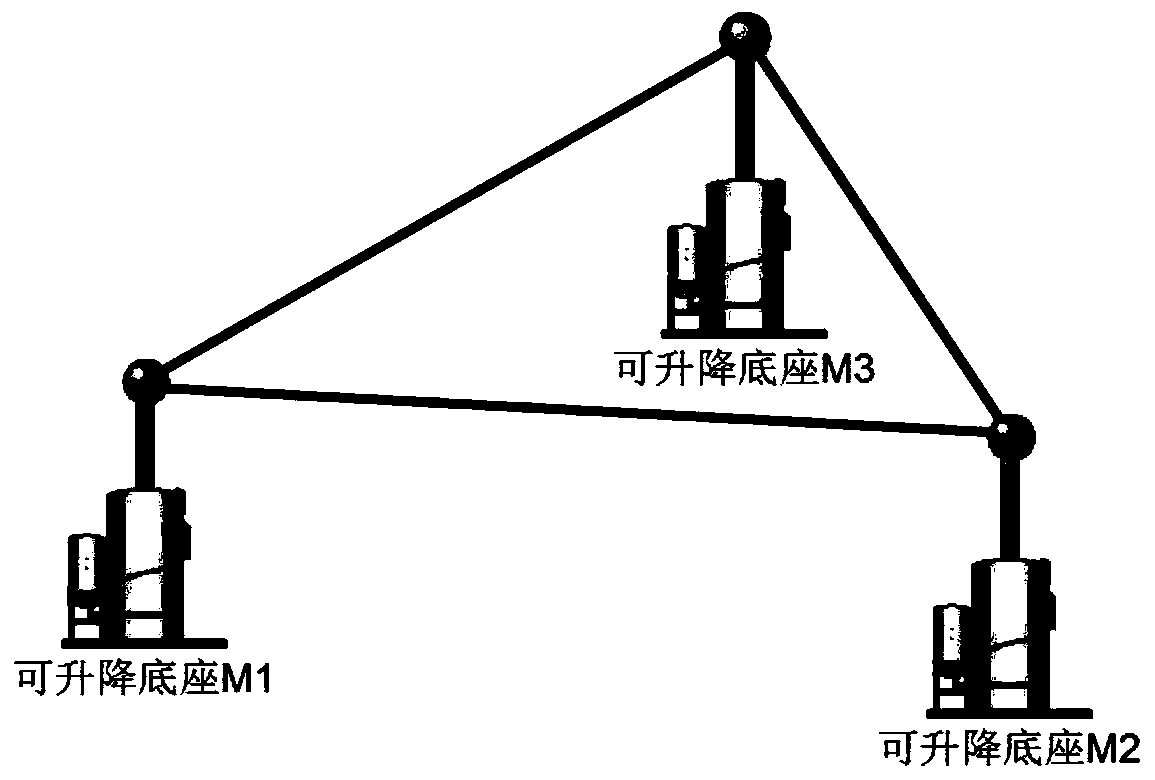

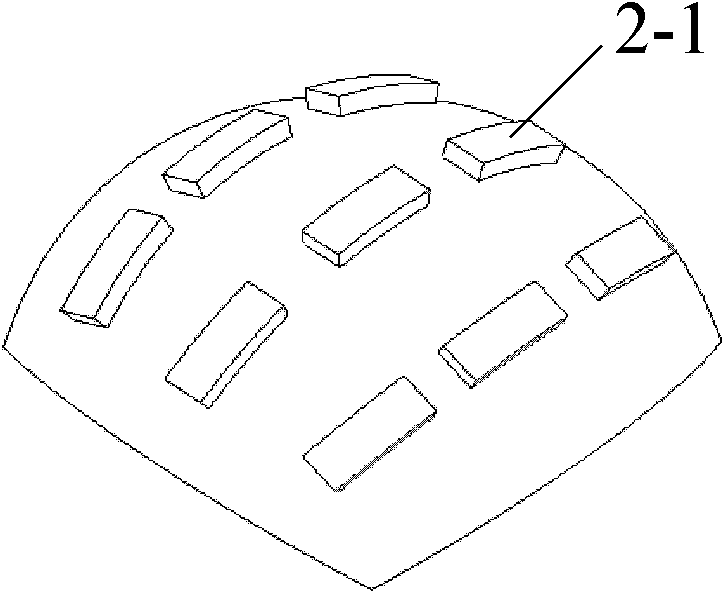

Three-dimensional scanner space coordinate positioning method

InactiveCN110645928ASolve the problem of control point deploymentSolve the problem of controlMeasurement devicesScannerComputer graphics (images)

An embodiment of the invention discloses a three-dimensional scanner space coordinate positioning method, which can calculate scanner coordinate values of a to-be-measured point in an object. The three-dimensional scanner space coordinate positioning method comprises the steps of: arranging a reference coordinatograph on the periphery of the object; capturing scanner coordinate values of a plurality of control points on the reference coordinatograph by means of a three-dimensional scanner; taking the plurality of control points as reference nodes, and establishing a spatial position topological relation between the to-be-measured point in the object and the plurality of control points on the reference coordinatograph under a scanner coordinate system; and calculating scanner coordinates ofthe to-be-measured point by utilizing the scanner coordinates of the control points according to the topological relation. The three-dimensional scanner space coordinate positioning method overcomesthe defect that the three-dimensional scanner cannot capture internal points of the object, indirectly captures the to-be-measured point in the object through scanning tripod positioning points of theexternal coordinate reference coordinatograph, makes the deployment and control mode in the scanner calibration process more flexible, and improves the calibration quality.

Owner:HORIZON MICROPORT MEDICAL TECH BEIJING CO LTD

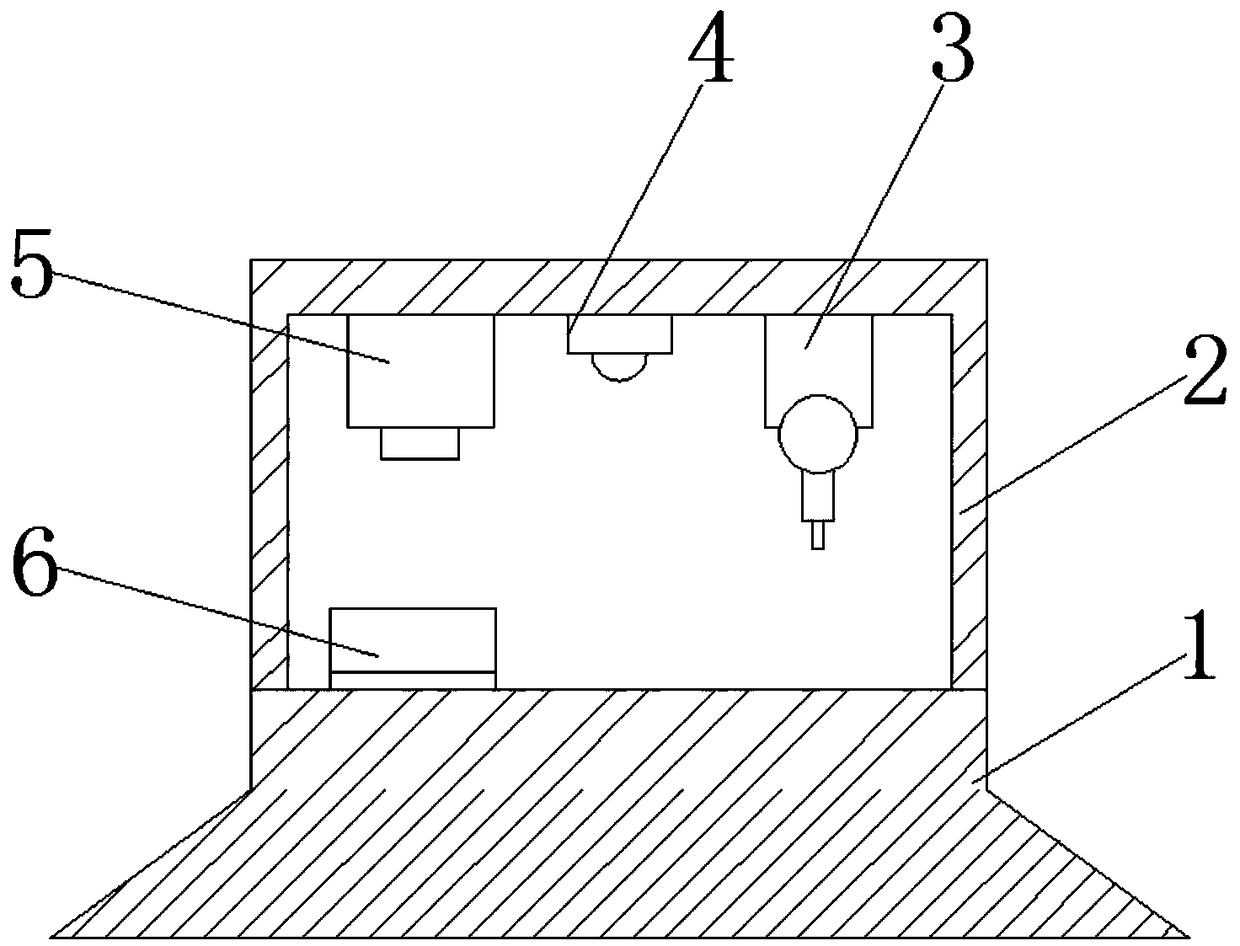

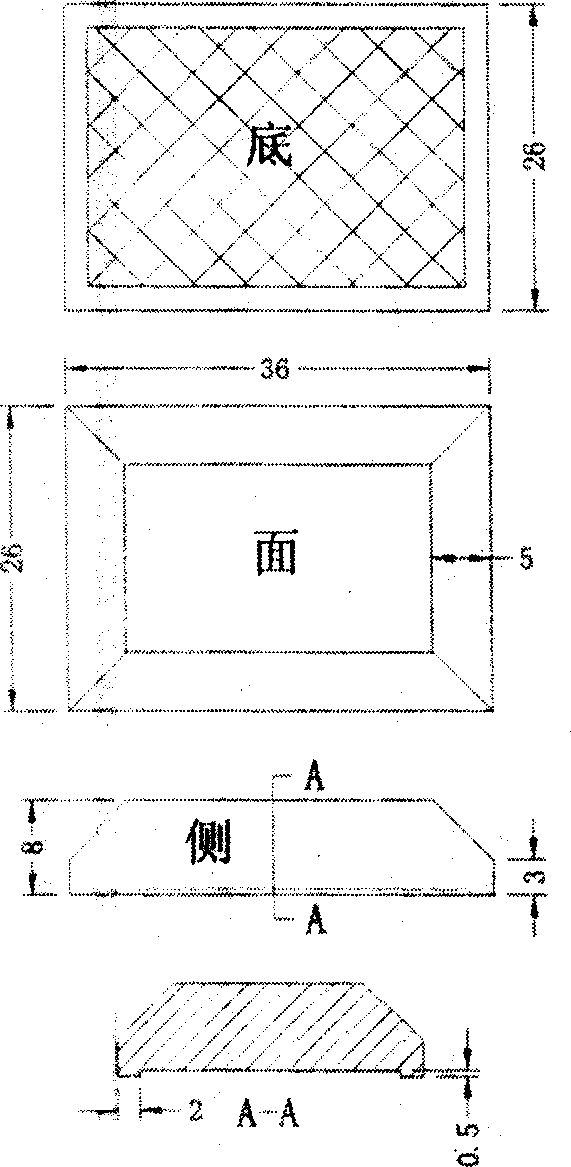

Waterproof and dustproof apparatus of vertical plumb coordinatograph and installation method thereof

InactiveCN105222735AImprove protectionStable working environmentMeasurement devicesSlagWorking environment

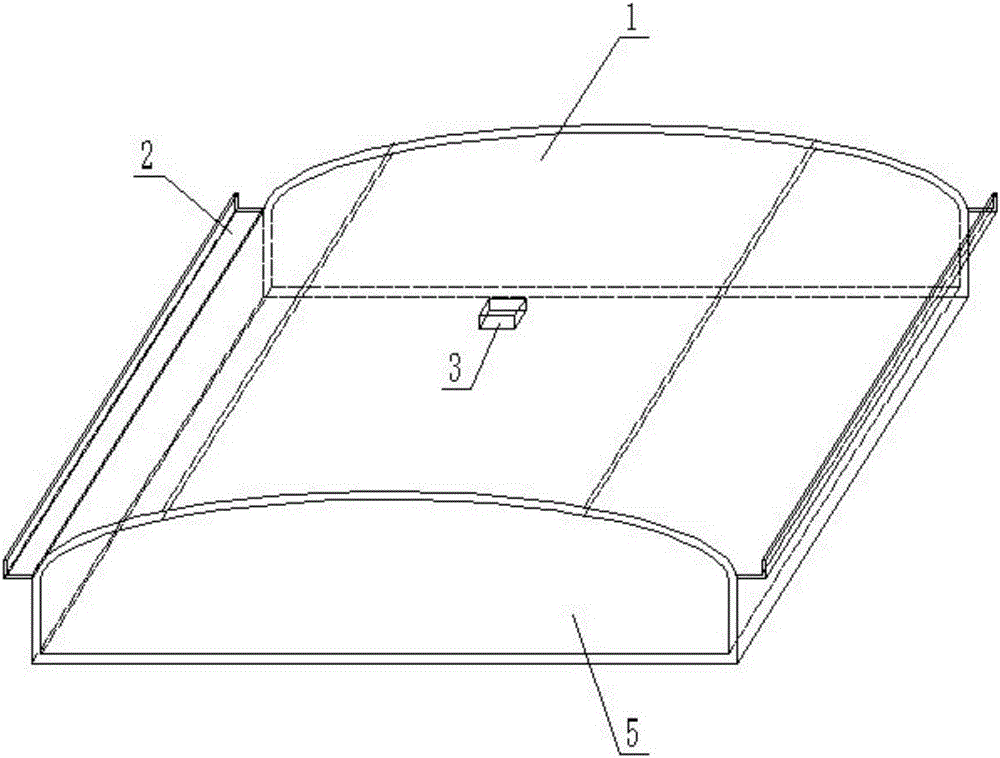

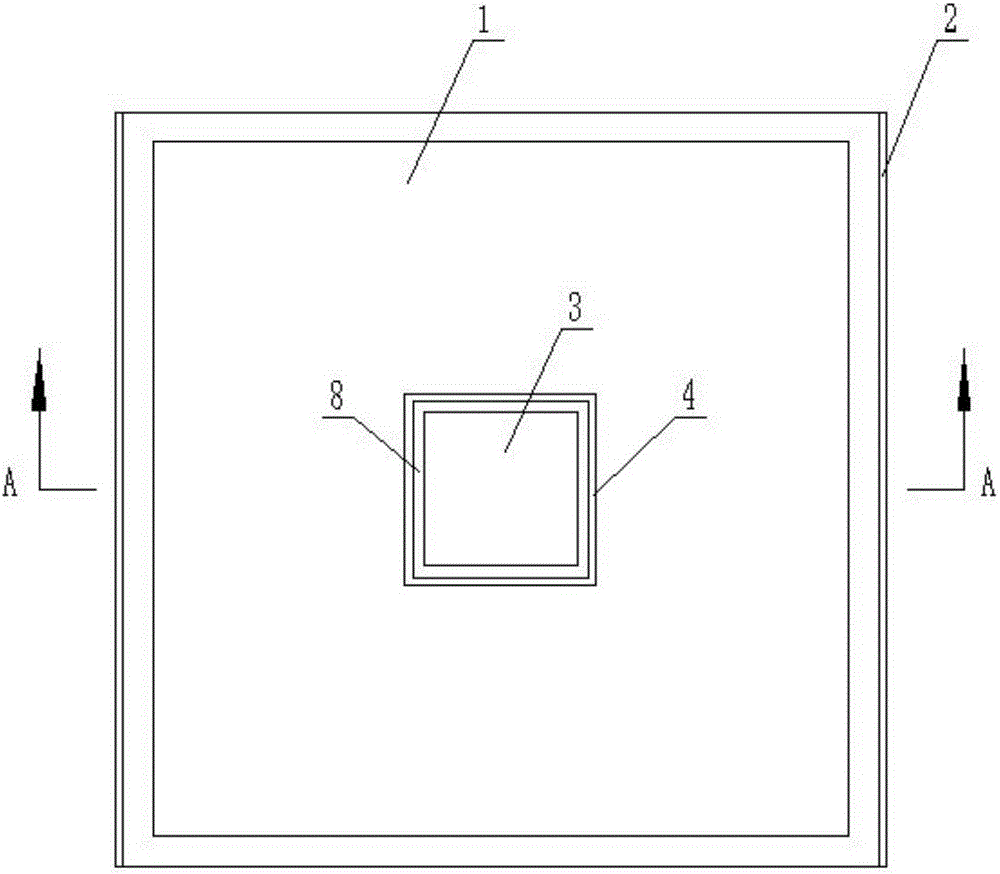

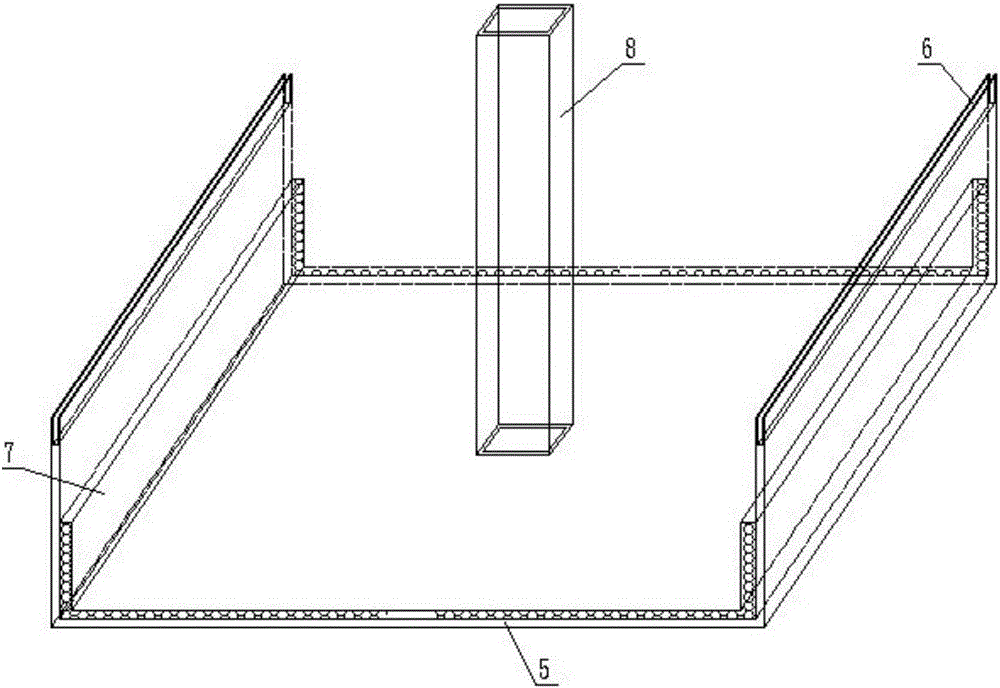

The invention discloses a waterproof and dustproof apparatus of a vertical plumb coordinatograph and an installation method thereof. The apparatus comprises a box body and a cover plate, wherein the box body and the cover plate are in a full-transparent mode. The box body has a U-shaped structure and clamp grooves B are formed in the tops of the two sides. The cover plate is in an inverted-U shape and the two sides of the bottom are inserted into the clamp grooves B. A vertical cylinder that is arranged vertically is fixedly connected to the middle part inside the box body; a rectangular hole corresponding to the vertical cylinder is formed in the middle part of the top end of the cover plate; a clamp groove A matching the top end of the vertical cylinder is formed around the rectangular hole; and the top end of the vertical cylinder is inserted into the clamp groove A. According to the invention, a vertical plumb coordinatograph is fixedly installed in a sealed apparatus and thus the whole vertical plumb coordinatograph can be protected well, thereby effectively eliminating adverse factors like external moisture, dust and dropped slag stones and providing a long-term stable working environment for the vertical plumb coordinatograph.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Buckle tower deviation monitoring device

InactiveCN111578903AHigh measurement accuracyImprove reliabilityIncline measurementCoordinatographBuoy

The invention provides a buckle tower deviation monitoring device. The buckle tower deviation monitoring device comprises a buckle tower strut perpendicular to a base. An indium steel wire is arrangedon the axis of the buckle tower strut, a coordinatograph is fixed at the top end of the buckle tower strut, a buoy is fixed above the coordinatograph, the top end of the indium steel wire is connected to the bottom of the buoy, and the indium steel wire vertically penetrates through the coordinatograph downwards; and the coordinatograph is electrically connected to the storage battery. The indiumsteel wire is located in the protection tube and is always in a vertical tensioning state after being connected with the buoy, the device belongs to an independent working system, and is not influenced by factors such as elastic deformation, bending, and boundaries of the buckling tower and external wind and rain, and meanwhile, the plumb line coordinatograph and the buckling tower structure aresynchronously deformed, so that the center offset of the top of the buckling tower can be accurately obtained, the measurement precision is high, and the reliability and durability are good.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

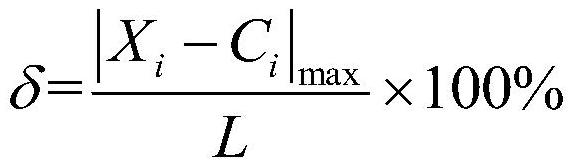

Photoelectric plumb coordinatograph detection device and detection method

PendingCN113267172AEasy accessAchieve fine-tuningUsing optical meansPlumb lines for surveyingNuclear powerEngineering

The invention belongs to the technical field of nuclear power, and particularly relates to a photoelectric plumb coordinatograph detection device and detection method. According to the invention, different preset distances are arranged between the lapping positions of different standard blocks and the plumb line in the reference state, so that under the condition that the plumb line can be lapped on the lapping position of each standard block, the actual distance between the current position of the lower end of the plumb line and the position of the lower end of the plumb line in the reference state is the preset distance corresponding to the standard block, and the photoelectric plumb line coordinatograph can measure the current measured distance of the bottom end of the plumb line; and in this way, accuracy detection can be carried out on the photoelectric plumb line coordinatograph in a running state under the condition that the plumb line coordinatograph is not disassembled.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +2

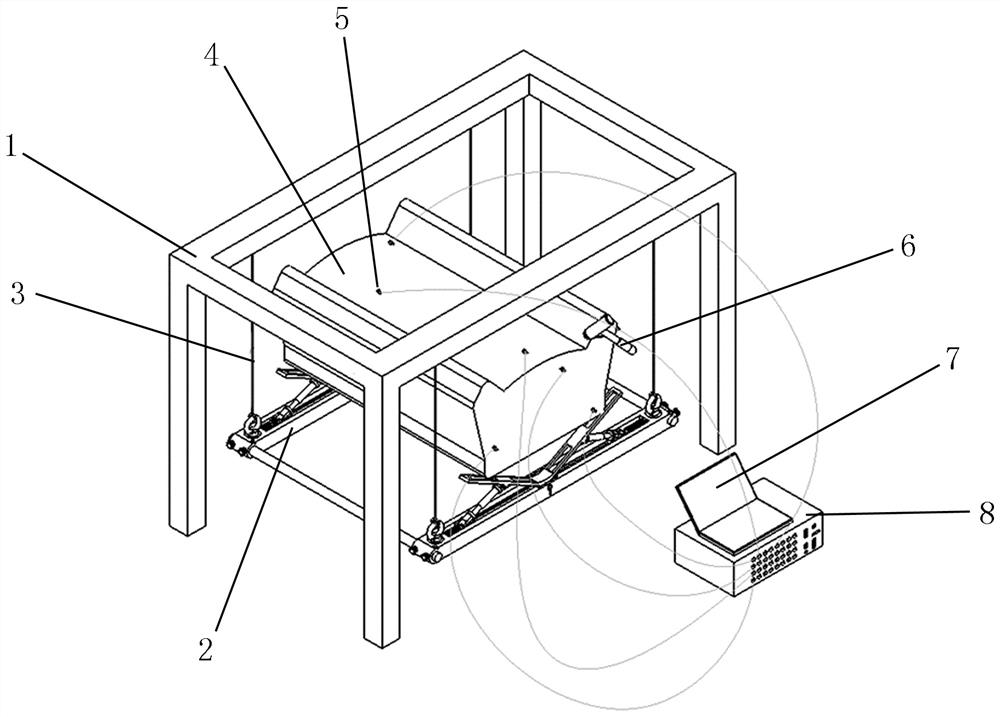

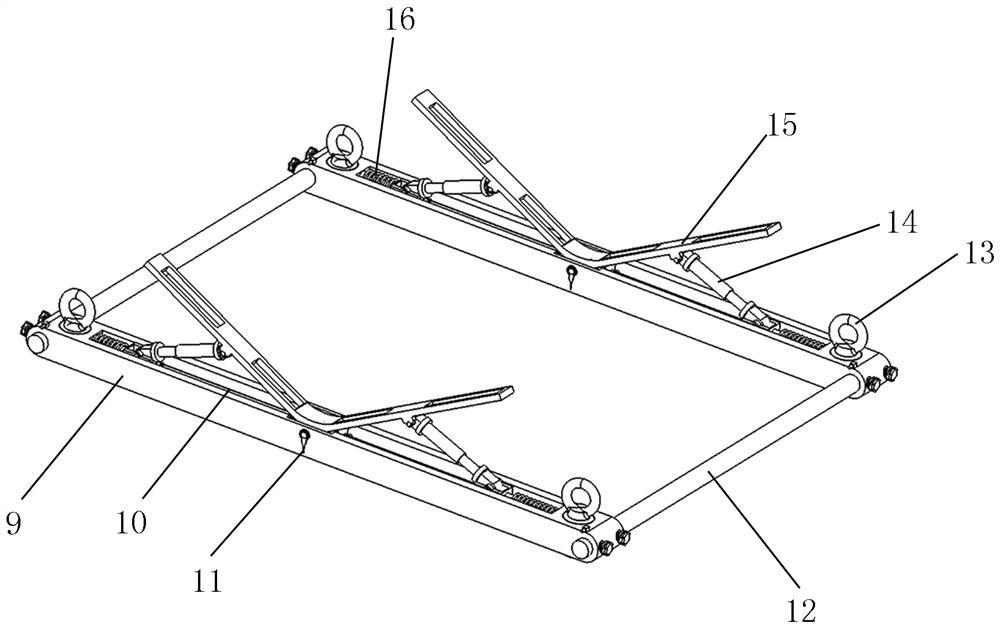

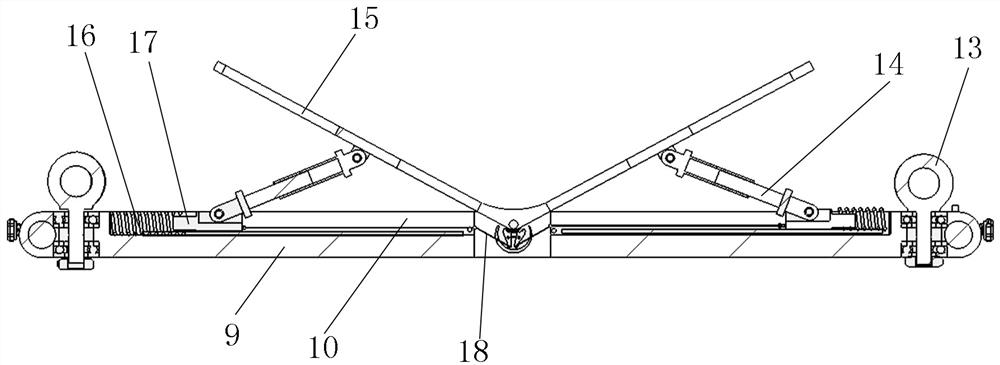

Inertial parameter measurement platform and method based on frequency response function mass line

PendingCN112857670AEasy to operateHigh measurement accuracyStatic/dynamic balance measurementDisplay deviceData acquisition

The invention discloses an inertial parameter measurement platform and method based on a frequency response function mass line. The platform comprises a support frame, a balance platform, three-axis acceleration sensors, a force hammer, a data collector and a display device, wherein the balance platform is suspended in the support frame through a flexible rope in a level water manner, a to-be-measured structural member is placed on the balance platform, the multiple three-axis acceleration sensors are respectively arranged on the to-be-measured structural member according to measurement requirements, the force hammer is used for applying excitation to the to-be-measured structural member, the three-axis acceleration sensors and the force hammer are respectively connected with the data collector through data lines, and the data collector is also connected with the display device and is used for displaying collected data. According to the invention, the platform is simple in balance adjustment operation and can be disassembled and expanded automatically; and coordinates of an excitation point and a response point can be accurately measured by means of geometric parameters of a measurement platform, repeated measurement of a three-dimensional coordinatograph is not needed, inertial parameters and errors of an experimental platform can be known, and measurement accuracy can be improved when inertial parameters of a to-be-measured component are calculated.

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

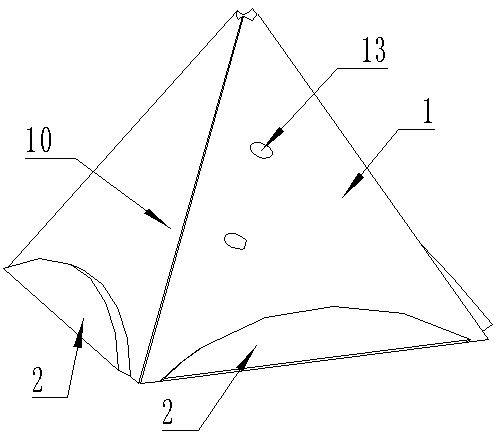

Water drainage device for pendulum coordinatograph

PendingCN108458700AConvenient for centralized processingSolve the problem of easy dripping and splashing affecting detectionSurveying instrumentsSputteringWater flow

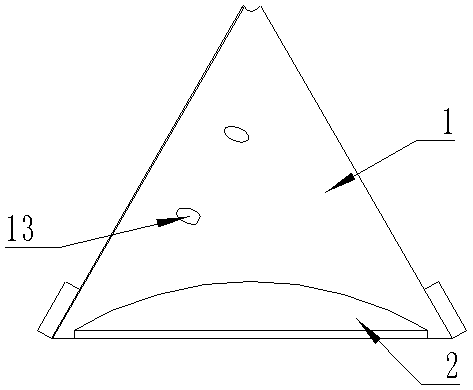

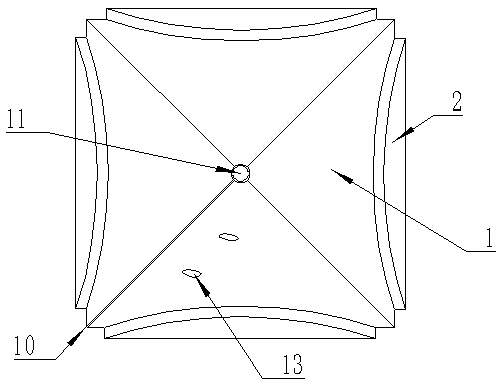

The invention discloses a water drainage device for a pendulum coordinatograph, relates to the field of peripheral auxiliary tools of the pendulum coordinatographs, and aims at the technical problemsthat a detection result is affected by the fact that a conventional waterproof and dustproof hood sputters water easily and the service life is affected by the fact that a fixing device is easy to oxidize and corrode. The water drainage device comprises a body, wherein the body is of a right square pyramid structure; a pendulum hole for installing a pendulum in a penetrating manner is formed fromthe top point of the pyramid to the bottom surface; a drainage block is fixedly arranged at the triangular lower part of the body; the drainage block is of an arc structure; the circle center of the arc is located in the bottom surface direction of the body, and a distance between two end points of the arc structure is shorter than the edge length of the body. Through the adoption of the body of the right square pyramid structure and the fixed arrangement of the drainage block at the triangular lower part of the body, water flow can be guided to four bottom corners of the body along an arc-shaped door of the drainage block, so as to facilitate centralized treatment, and the problem of influence on the detection due to easy water dropping and sputtering in the prior art is solved.

Owner:大唐水电科学技术研究院有限公司

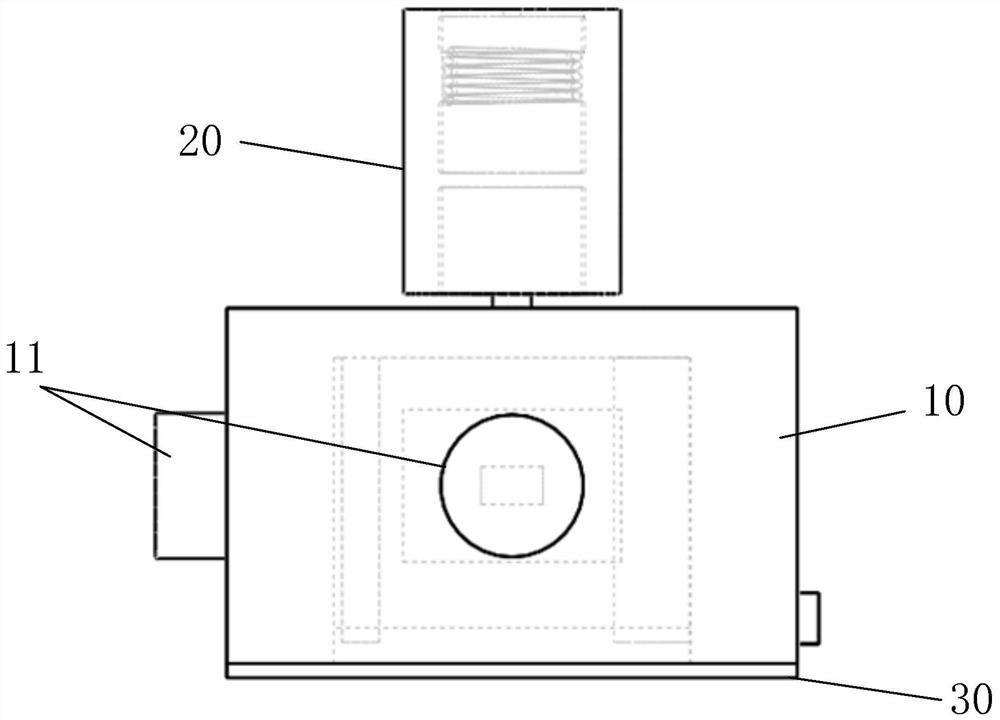

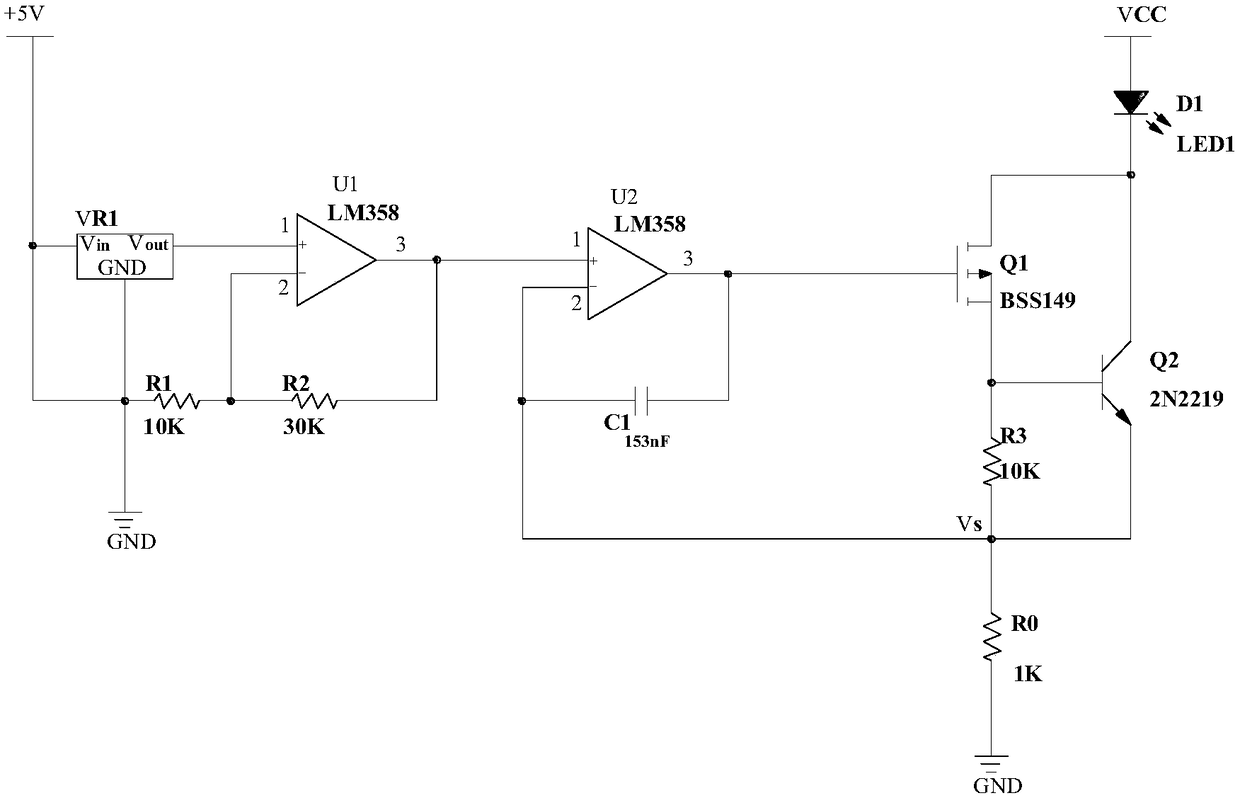

All-day and full-automatic photoelectric plumb line coordinatograph

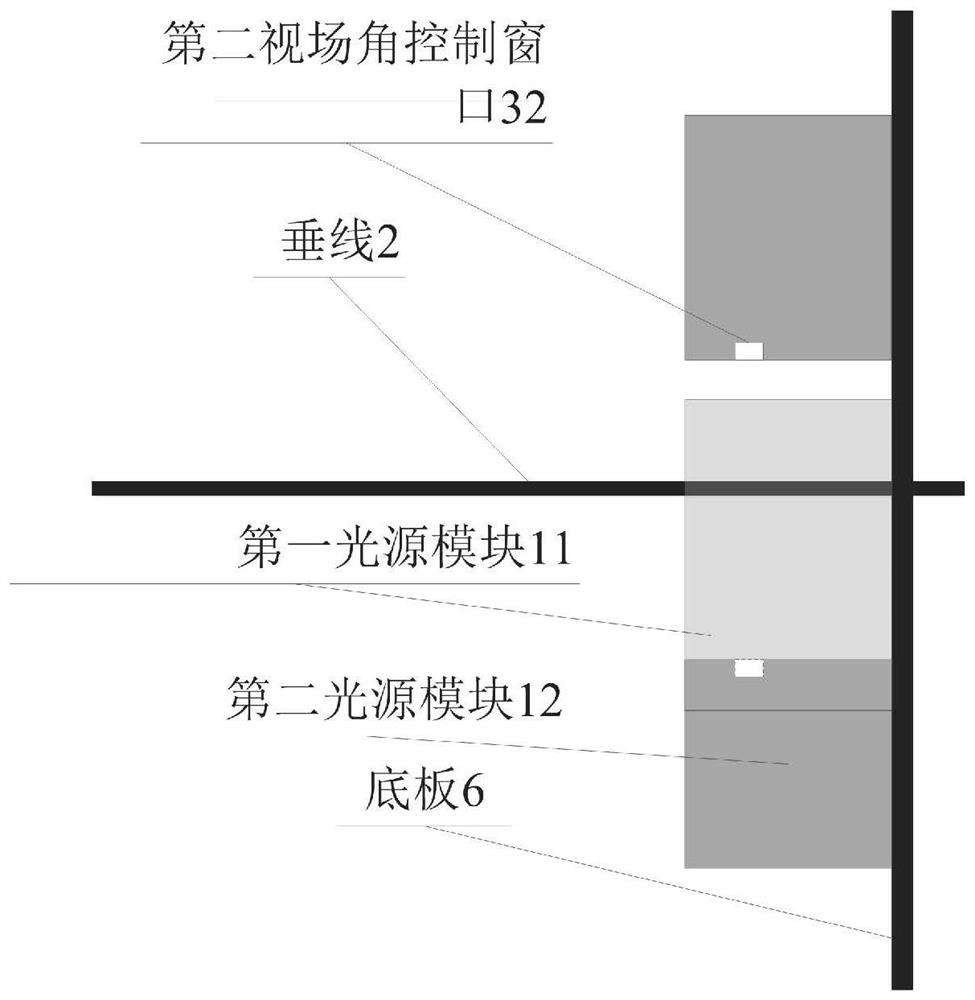

PendingCN113776432AImprove adaptabilitySuppress ambient background lightUsing optical meansPhoto irradiationEngineering

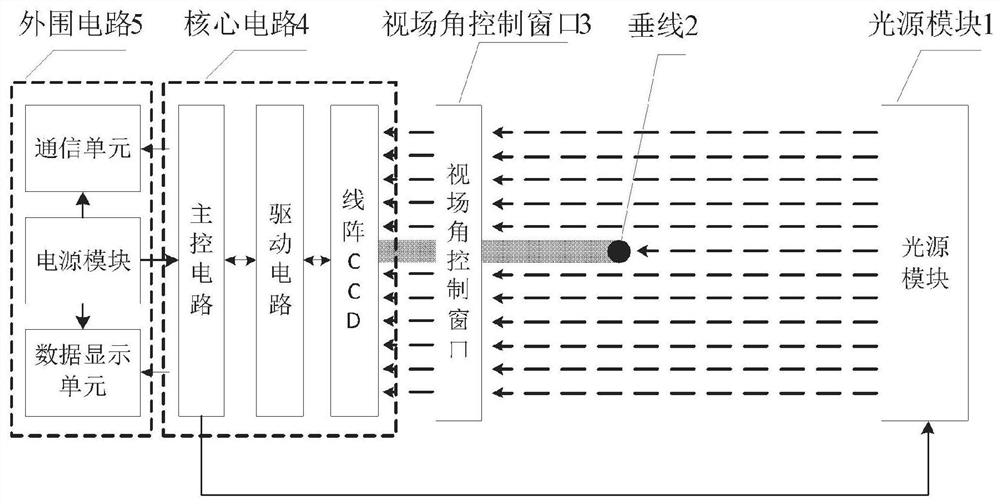

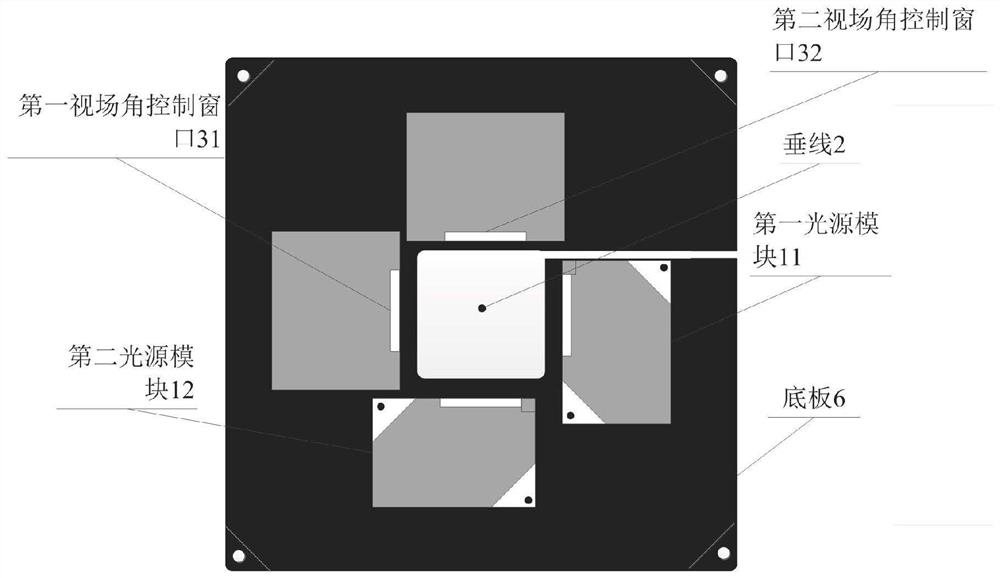

The invention discloses an all-day and full-automatic photoelectric plumb line coordinatograph which comprises a light source module, a plumb line, a field angle control window, a core circuit and a peripheral circuit. The core circuit is respectively connected with the peripheral circuit and the light source module and is used for controlling the light source brightness of the light source module; the peripheral circuit is used for providing voltage; the plumb line is fixed on a measured building; the light source module and the field angle control window are arranged on the two opposite sides of a plumb line respectively, and the light source module generates parallel light in the direction of the plumb line and the field angle control window. The plumb line generates a shadow under the irradiation of the parallel light, and the shadow is projected on the core circuit through the field angle control window and is detected and calculated by the core circuit. According to the coordinatograph, the field angle control window is adopted, environment background light in parallel light can be effectively inhibited, and the detection precision and the all-day environment adaptability are improved.

Owner:中冶检测认证有限公司 +1

Laser three-dimensional scanning coordinatograph

ActiveCN111879255AImprove the protective effectPlay a regulating roleUsing optical meansEngineeringCoordinatograph

The invention relates to the technical field of scanning coordinators, and discloses a laser three-dimensional scanning coordinator which comprises a scanner body, a scanning camera device is fixedlyconnected to the interior of the scanner body, and a movable rod is movably connected to the interior of one side of the front face of the scanner body in a sleeved mode. According to the laser three-dimensional scanning coordinatograph, springs are fixedly connected to the interior of a buffer box on the lower portion of the device, meanwhile, a lower supporting plate is installed on the lower portions of the springs, when the laser three-dimensional scanning coordinatograph is used, vibration can be buffered through the springs, and meanwhile, when the laser three-dimensional scanning coordinatograph is used, a threaded limiting rod is fixedly connected to one side of the upper portion of the buffer box; during use, the threaded limiting rod can be rotated to drive the distance between the lower portion of the threaded limiting rod and the lower supporting plate to be adjusted, so that the moving space of the lower supporting plate in the lower buffering box can be adjusted during use, and the buffering space can be adjusted during use.

Owner:广州天域科技有限公司

Coordinate acquisition device based on geographic information and use method thereof

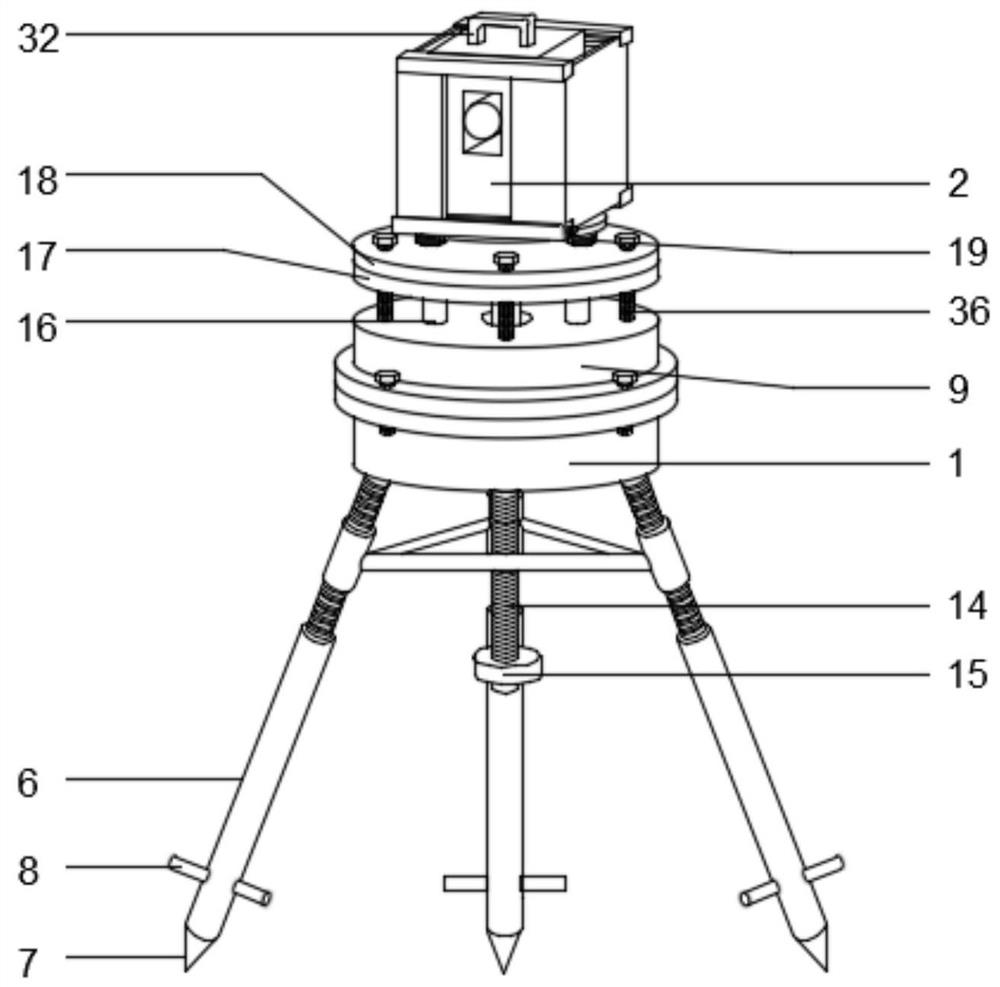

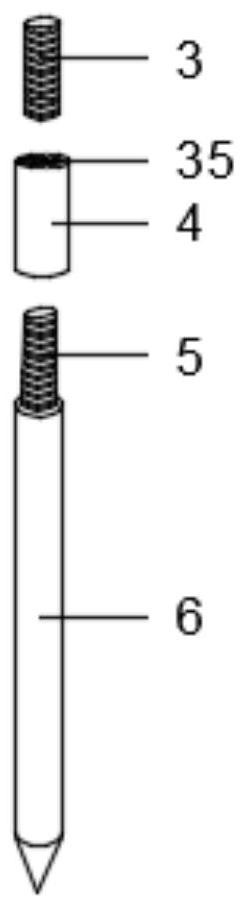

PendingCN113958834AGuaranteed stabilityImprove accuracySurveying instrumentsStands/trestlesProtection mechanismControl engineering

The invention discloses a coordinate acquisition device based on geographic information and a use method thereof, and relates to the technical field of surveying and mapping. The coordinate acquisition device comprises a mounting base and a coordinatograph body, the bottom of the mounting base is provided with a supporting mechanism, the top of the mounting base is provided with a leveling mechanism, the peripheral surface of the coordinatograph body is provided with a protection mechanism, the supporting mechanism comprises a first screw rod, an adjusting sleeve, a second screw rod, a supporting leg, a plug pin and a pedal plate, the leveling mechanism comprises an adjusting top seat, a fixed shaft, a ball body, a balancing weight, a fixed column and a fixed table, and the protection mechanism comprises a first fixed block, a second fixed block, a screw rod, a bearing, a movable block, a first connecting rod, a shielding plate, a sliding rod, a second sliding block and a second connecting rod. According to the coordinate acquisition device based on geographic information and the use method thereof, the stability of the coordinatograph body during use is ensured, the coordinatograph body is ensured to be in a horizontal state all the time, the coordinate acquisition accuracy is improved, protection is carried out on the coordinatograph body when the coordinatograph body is not used or under special conditions, and damage is avoided.

Owner:袁犁

Horizontal coordinatograph

The invention and its usage method belongs to finding horizon technique field fit to wide industries such as in building to find horizon in rugosity surface used as horizon surface, etc, more specifically a horizon coordinate device and its usage method. Uses proportional some coordinate plates with different thickness and coordinate base with height adjustable; makes horizon stay at arbitrary rugosity wall or ground. Coordinate base can adjust height or switch plate with different thickness, which is simple, quick; just adhibits some paste need no needle on base, pushes one or more times at suitable position, coordinate base will be fixed after minutes. It can save time and labor and decrease cost.

Owner:陈知丰

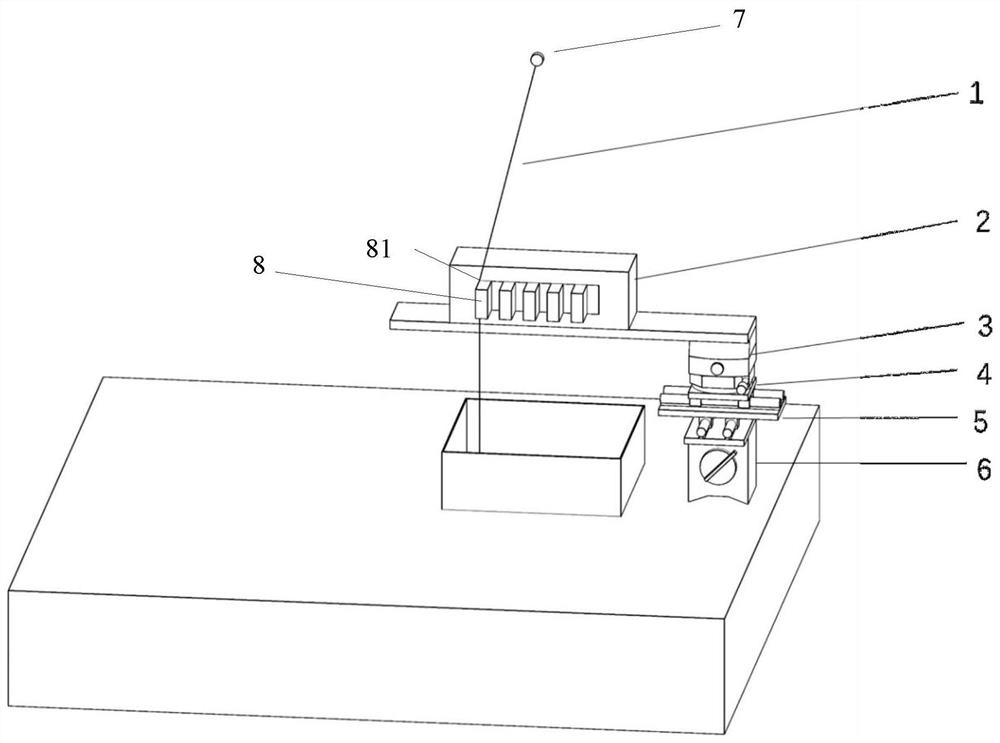

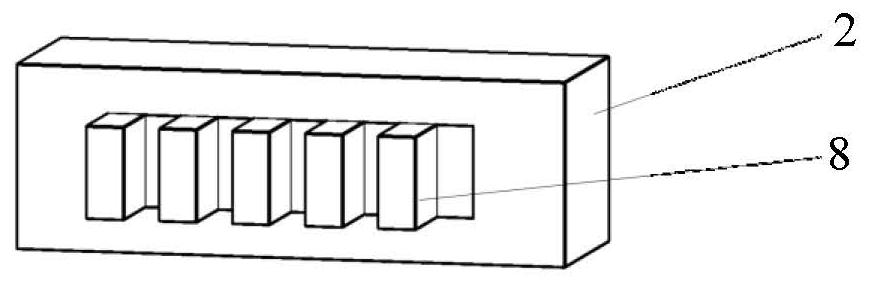

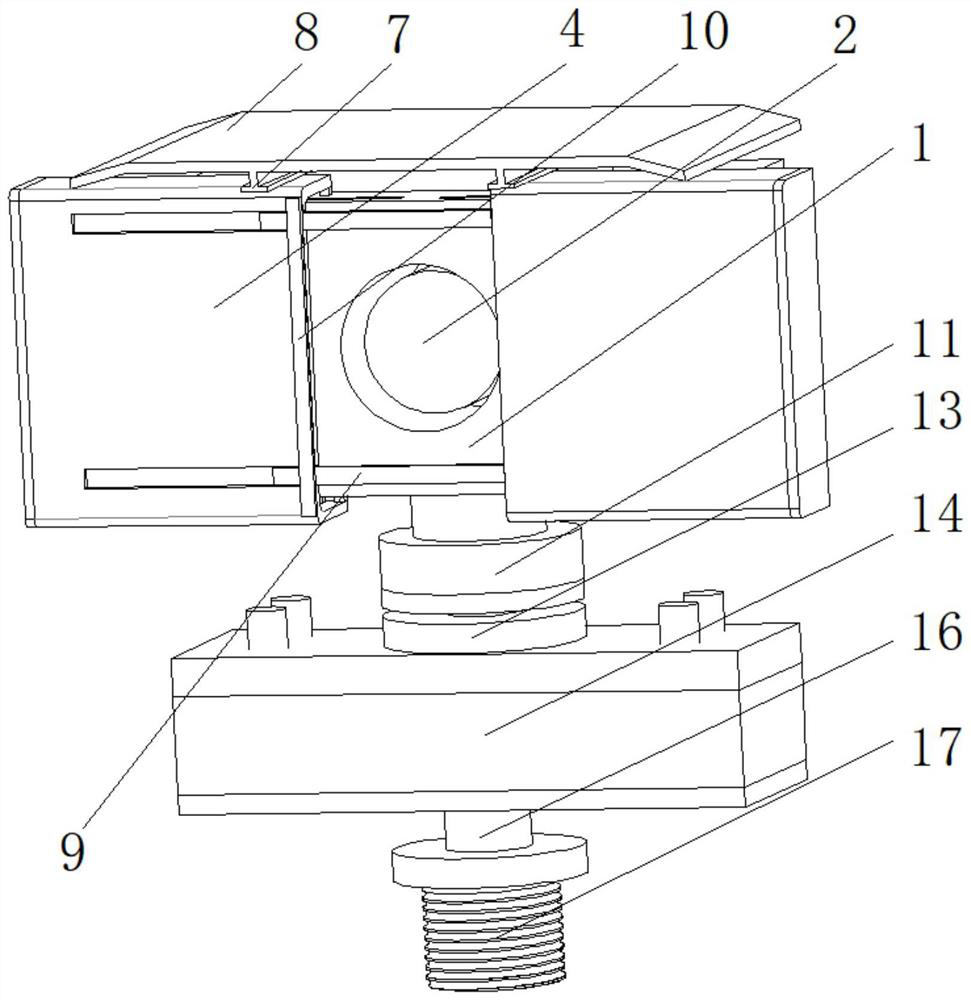

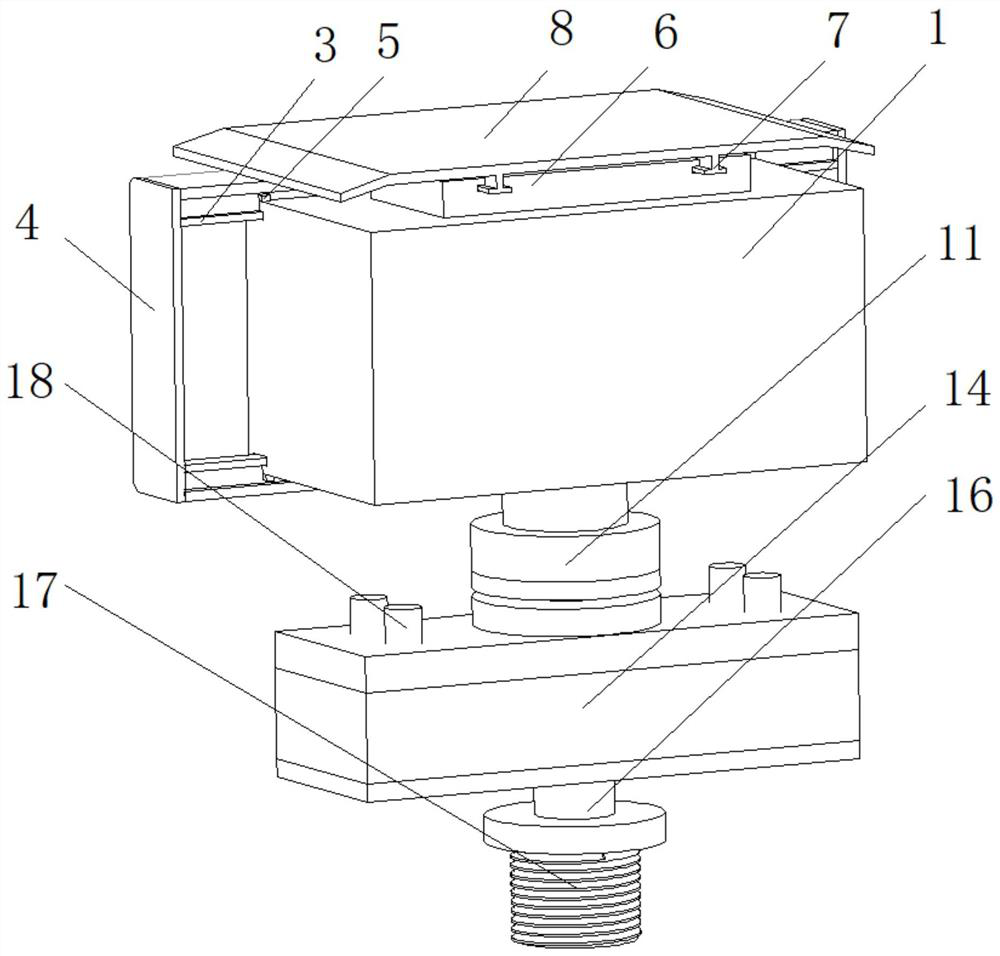

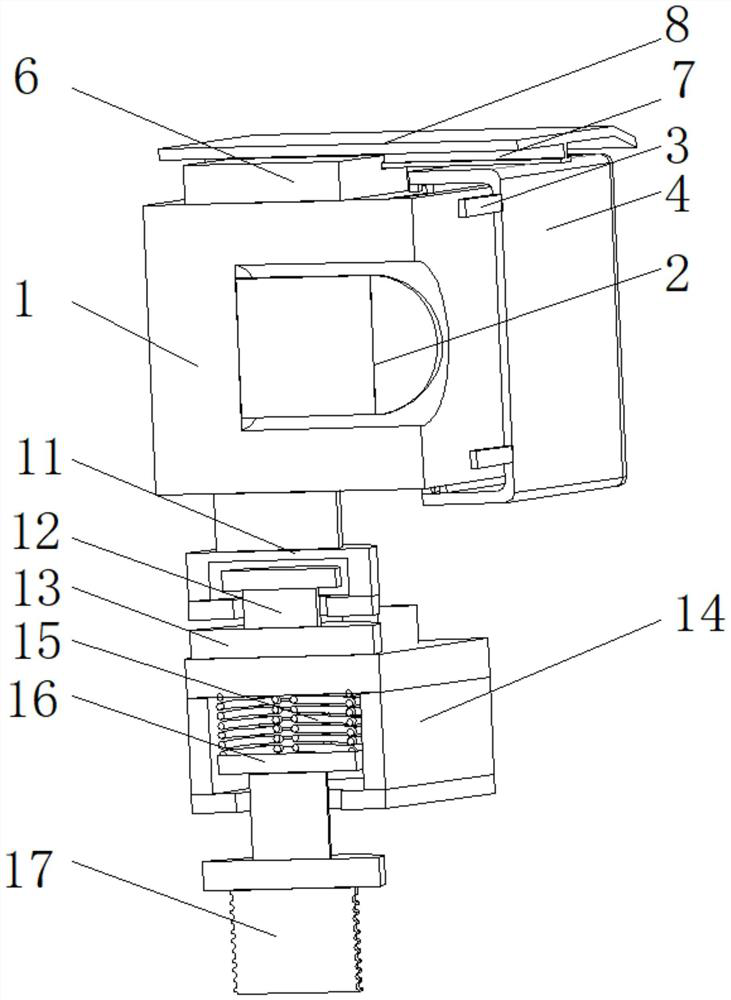

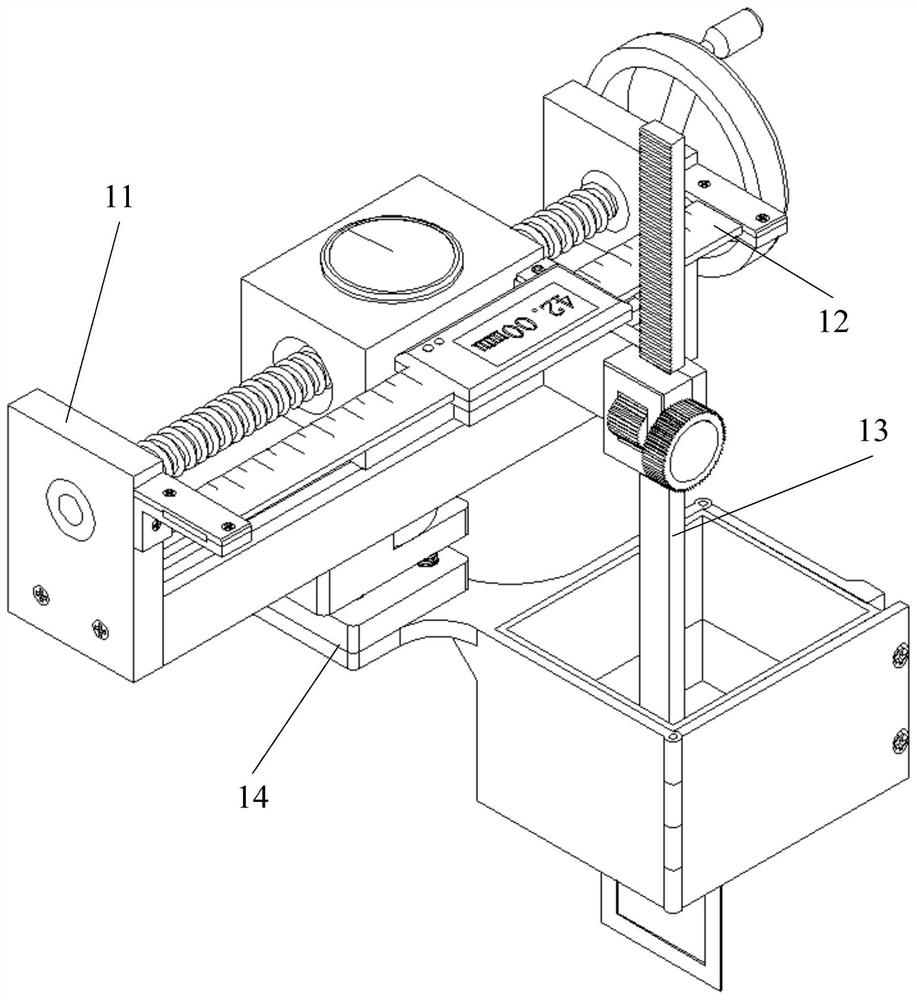

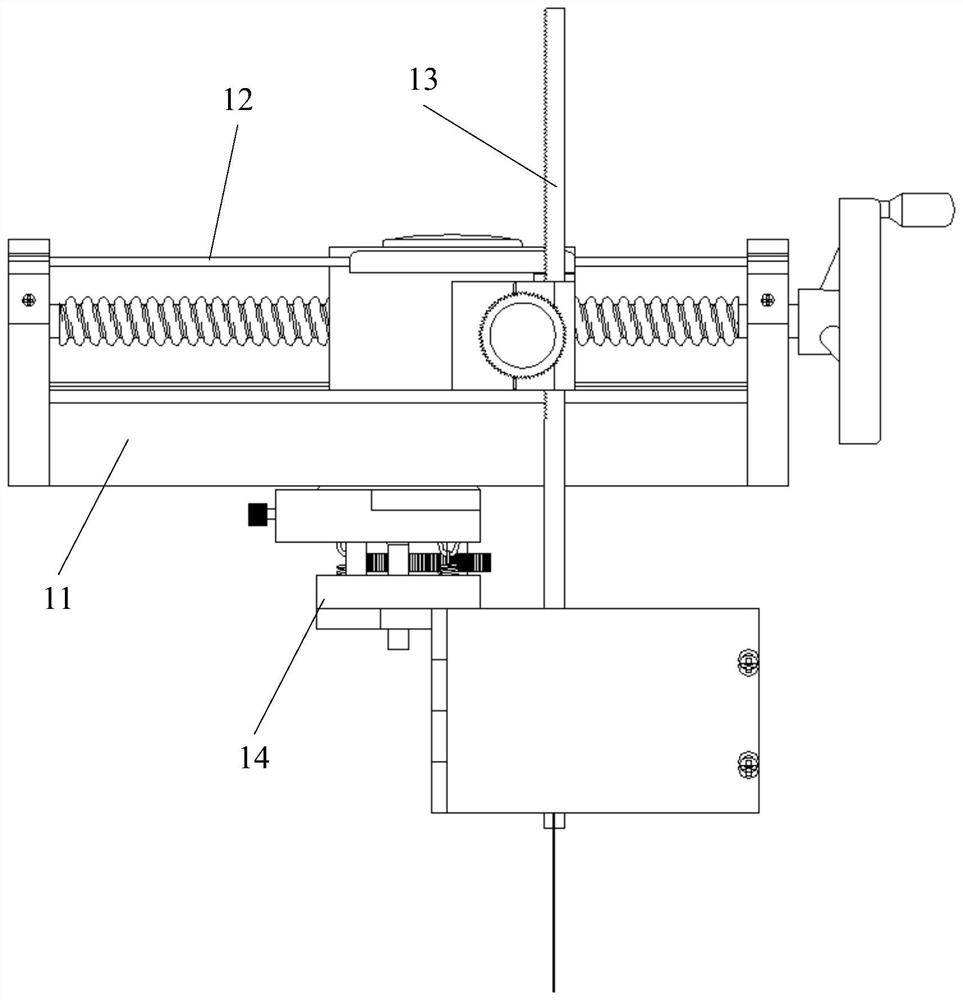

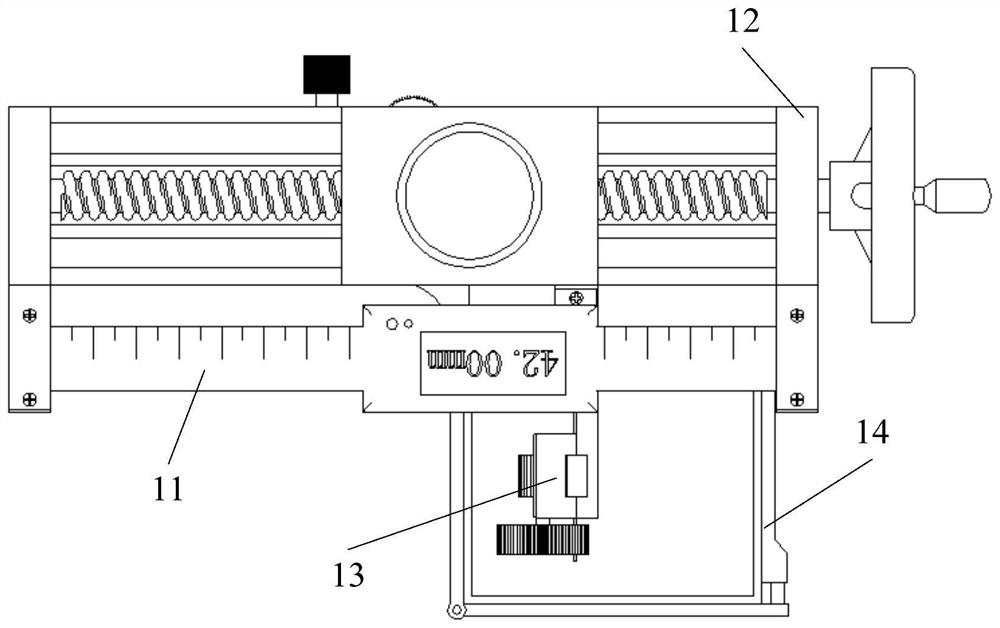

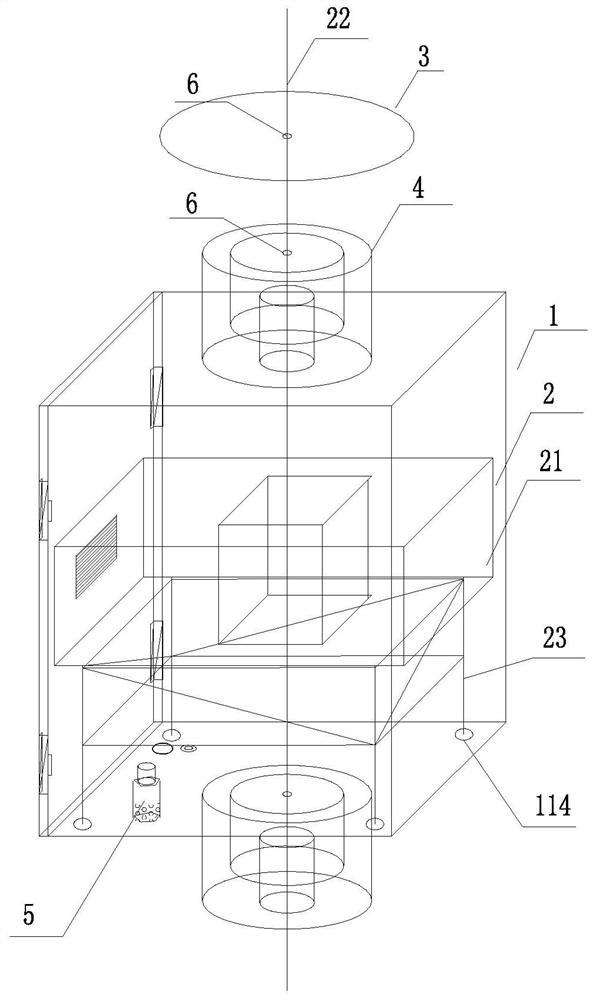

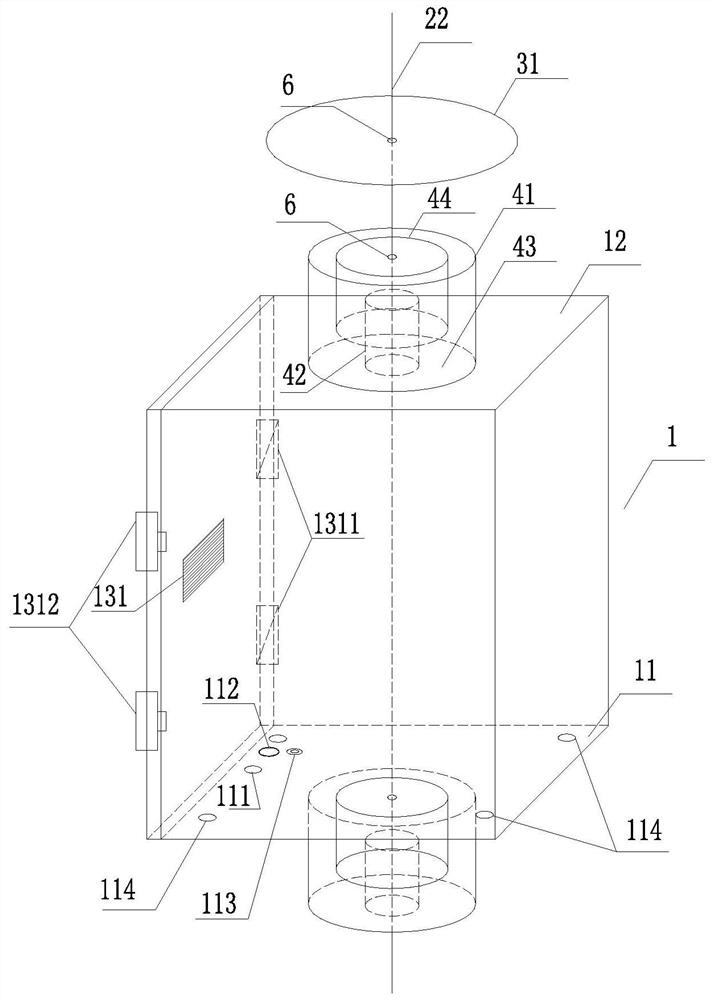

An on-site calibration device for a vertical line coordinate instrument

ActiveCN108469226BSolve the problem of online calibrationGuaranteed accuracyUsing optical meansVernier scaleEngineering

The invention provides the site calibration device of a vertical line coordinatograph. The site calibration device comprises a linear slide table mechanism, a vernier caliper mechanism, a measuring rod mechanism and a rotary leveling fixing pedestal. By using the device of the invention, the site calibration of the two measuring axes of the vertical line coordinatograph can be completed through one-step installation without disassembling an original vertical line coordinatograph, and the horizontality of the XY plane of the vertical line coordinatograph and whether the XY axis of the verticalline coordinatograph is orthogonal can be detected simultaneously so as to ensure the accuracy of calibration data. Through abandoning the vertical line of the vertical line coordinatograph and adopting the measuring rod mechanism, work efficiency can be increased.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Self-balancing wall surface laser coordinatograph

ActiveCN112212785AUsing optical meansElectromagnetic wave reradiationLaser rangingLiquid-crystal display

The invention discloses a self-balancing wall surface laser coordinator, two laser range finders are respectively arranged on one side surface and the top surface of a main body and are used for respectively obtaining the distances relative to a vertical wall surface, a horizontal wall surface or the ground; a mark button, a posture selection button and a main switch are arranged on the other sidesurface of the main body; a motor drive circuit, a control circuit, an attitude sensor and a lithium battery are all arranged in the main body, and after signals measured by the laser range finder are sent to the control circuit to be processed, a distance value is displayed on the liquid crystal display screen. The control circuit is further connected with the attitude sensor, processes an attitude signal detected by the attitude sensor and then sends the attitude signal to the motor driving circuit to control the motor, so that the main body is kept in a horizontal or vertical attitude. Thecoordinatograph can automatically keep horizontal, measure the accurate distance between the horizontal reference surface and the vertical reference surface, and display and mark the accurate distance in real time.

Owner:HANGZHOU DIANZI UNIV

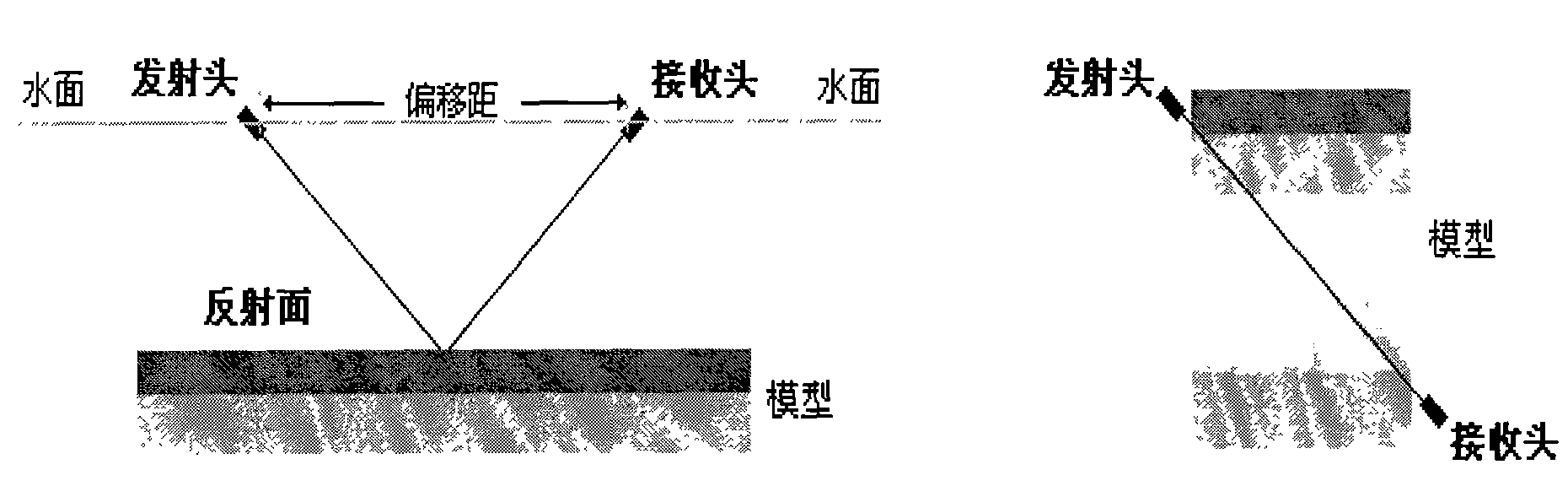

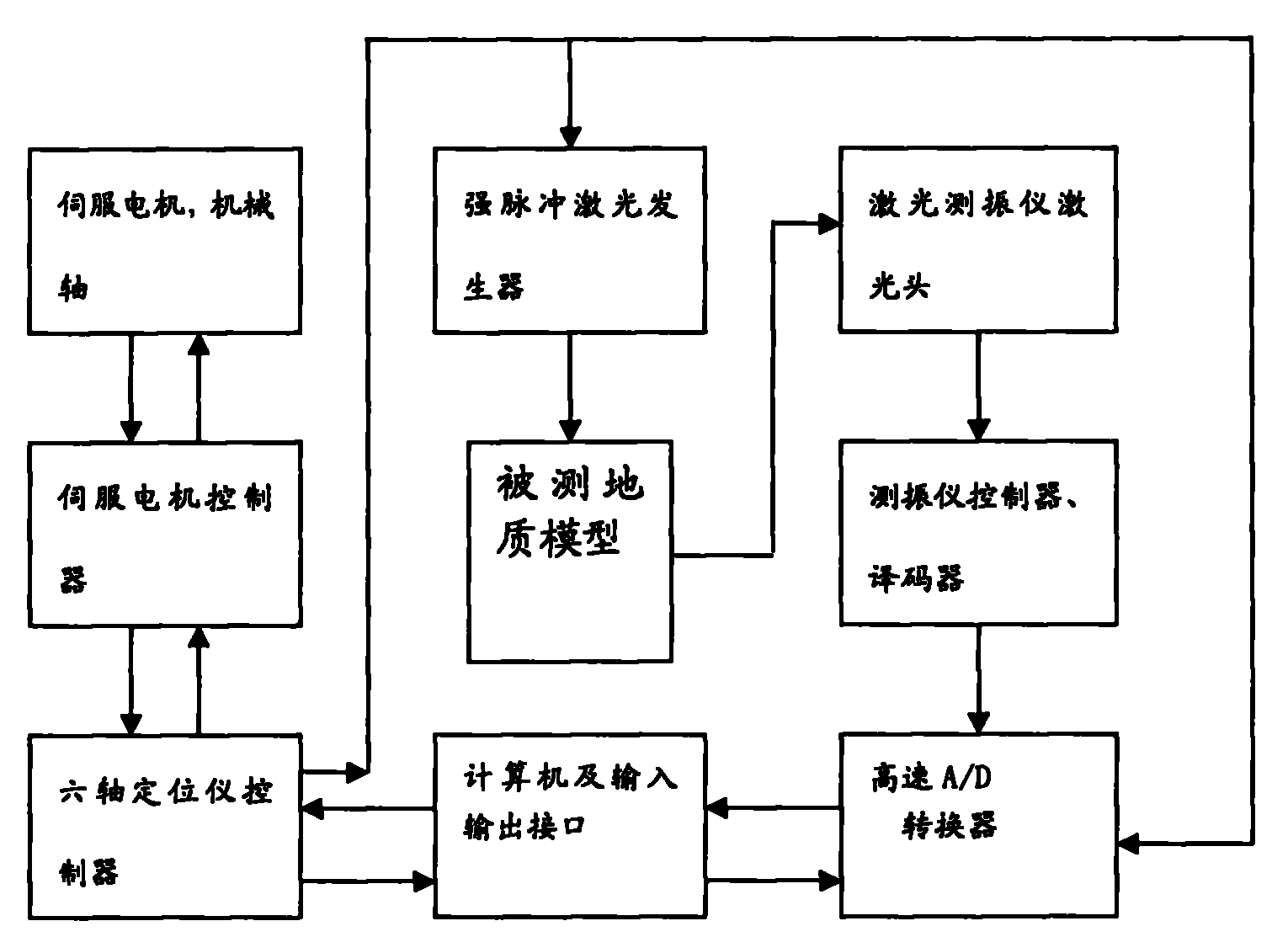

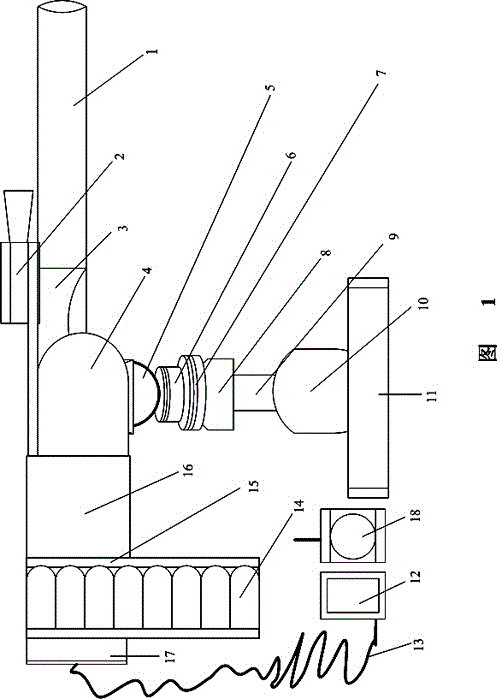

Laser ultrasonic detection system and detection method thereof

ActiveCN102053254BRealistic simulation effectLarge dynamic rangeSeismic energy generationSeismic signal receivers24-bitNon-contact ultrasound

The invention relates to a laser ultrasonic detection system and a detection method thereof. The system is used for generating and receiving field seismic exploration seismic waves simulated by an ultrasonic method under the indoor condition. A complete set of laser ultrasonic automatic acquisition system comprises a set of intense pulse laser source, a single-point laser Doppler seismograph, a three-dimensional laser Doppler seismograph, a 24-bit analog-to-digital converter, a three-dimensional coordinatograph and the like. The system solves the problems of a large number of conventional geologic model simulation methods, can perform single-point and three-component non-contact ultrasonic detection, and meets the requirement of modern geophysical exploration on fine and multi-component simulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

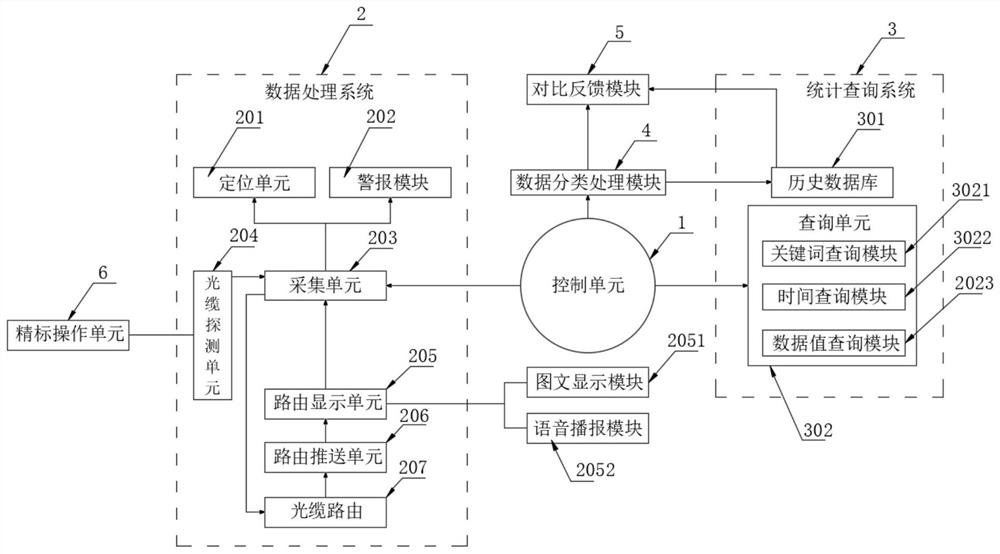

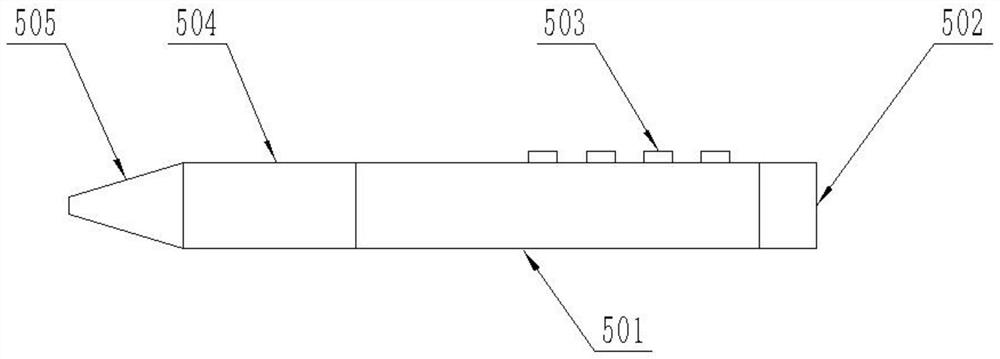

Handheld electronic optical cable route precise coordinatograph

InactiveCN113300761AImprove efficiencyQuality improvementElectromagnetic transmissionOther databases clustering/classificationData processing systemControl cell

The invention discloses a handheld electronic optical cable route precise coordinatograph, and belongs to the technical field of optical cable route checking. The handheld electronic optical cable route precise coordinatograph comprises a control unit, wherein the output end of the control unit is electrically connected with the input end of a data processing system; the data processing system comprises an acquisition unit; the input end of the acquisition unit is electrically connected with the output end of the control unit; and the input end of the acquisition unit is electrically connected with the output end of the optical cable detection unit. Compared with a traditional mode, the handheld electronic optical cable route precise coordinatograph has the advantages that foreground and background linkage and data two-way automatic connection can be achieved, association of system data and field real objects can be automatically achieved through position real-time presentation and comparison, system data can be automatically updated through field checking results, and comparative analysis can be conducted through a map. The coordinatograph is high in efficiency and good in quality, and can also automatically photograph and return the field instrument test result, thereby facilitating the online quality inspection of a manager, and further improving the management effect.

Owner:欧阳帆

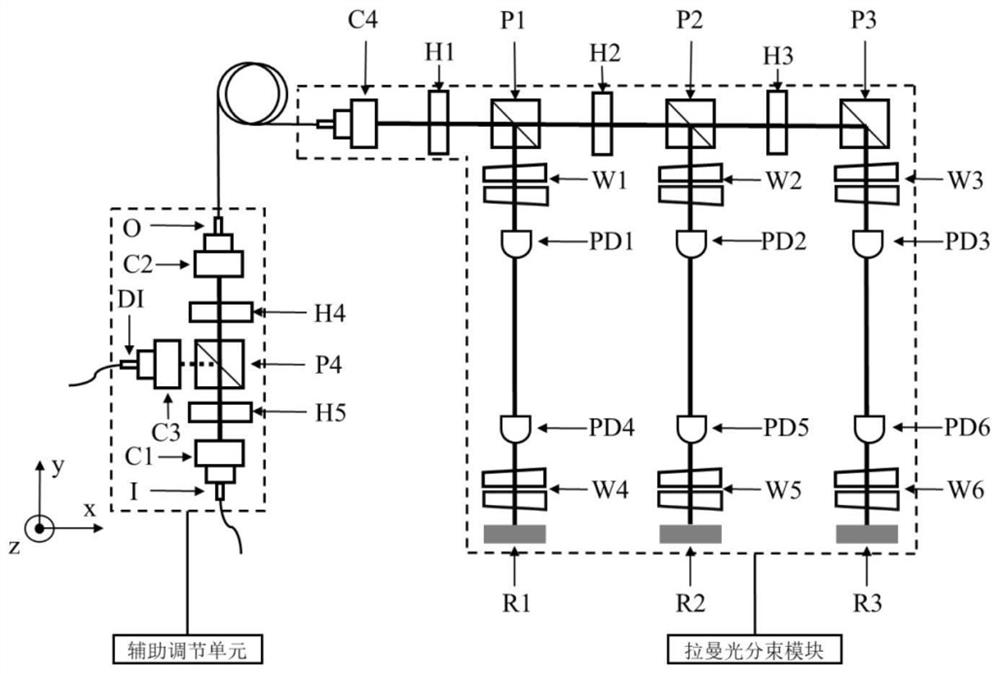

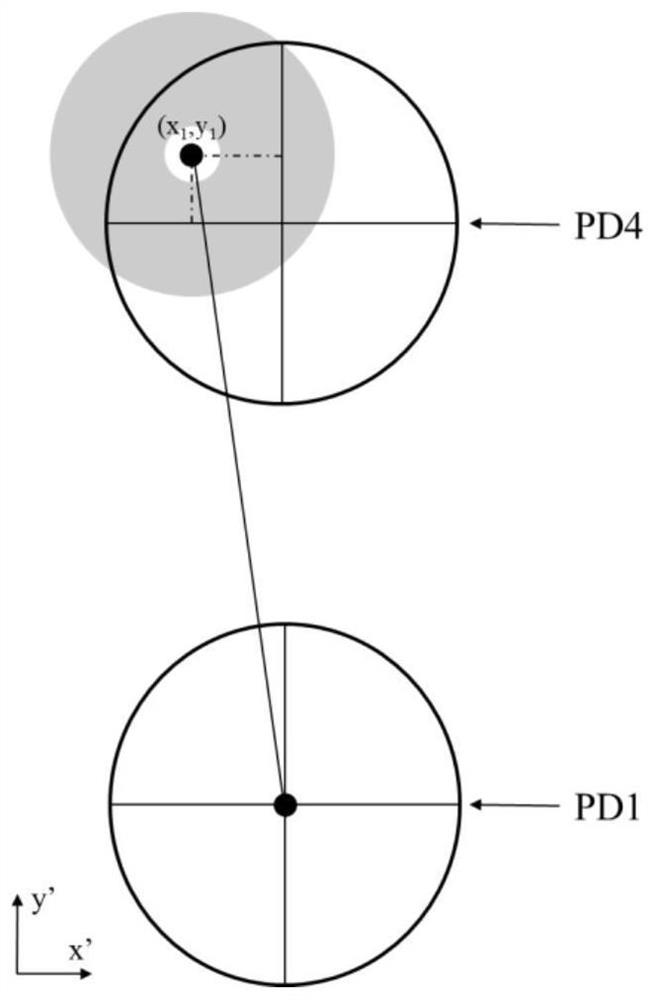

Device and method for high-precision adjustment and separation of parallelism of laser beams

The invention discloses a device for high-precision adjustment and separation of parallelism of laser beams. The device comprises a Raman light beam splitting module, an auxiliary adjustment unit, a laser light source, a position sensitive quadrant photodiode, a three-coordinate measuring instrument, a precision displacement table and the like. The invention further discloses a method for adjusting the parallelism of the separated laser beams at high precision, high-precision parallelism of three beams of Raman light and high coincidence of reverse light beams in the atomic interference gyroscope are realized by utilizing mutual cooperation of a three-coordinate instrument and a position sensitive quadrant photodiode, the method does not depend on the atomic interference process, and the total error is smaller than 57.6 microrad. In addition, the optical element and the quartz substrate are bonded and fixed by utilizing a hydroxyl catalytic bonding technology, so that a new way is provided for stably keeping high-precision parallelism of three beams of Raman light, and engineering application of the atom interference gyroscope is promoted.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS

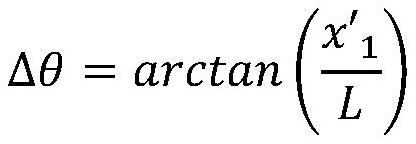

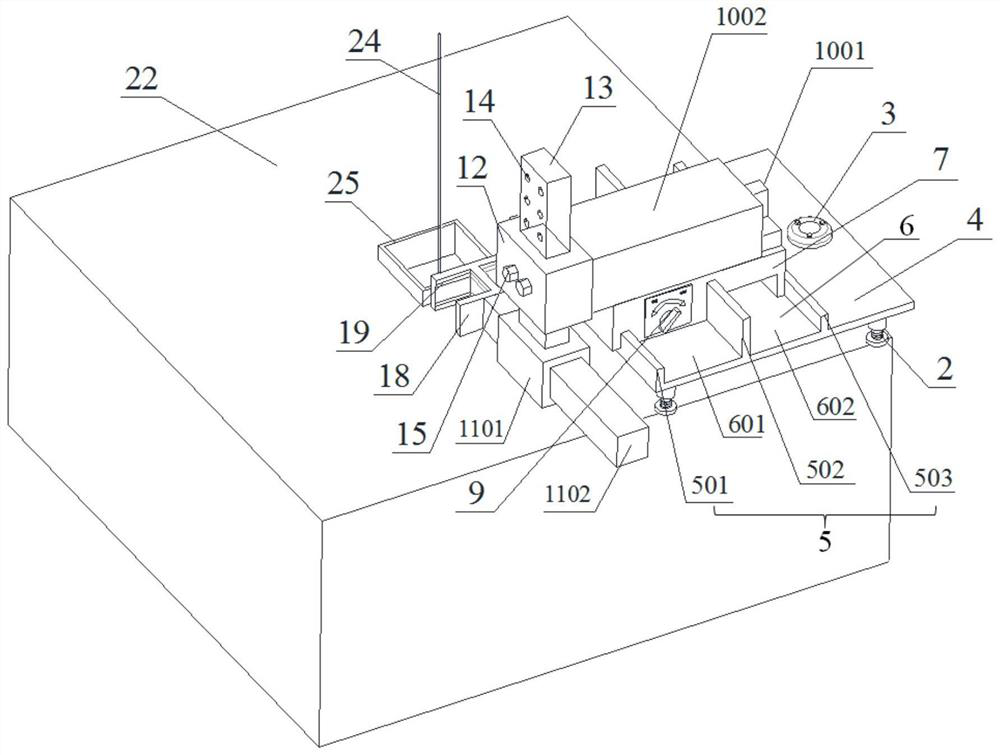

High-precision tube or hole effective tube or hole diameter and center intelligent measuring device and method

ActiveCN113251930BRealize the whole process automationHigh precisionSurveying instrumentsUsing optical meansLiquid storage tankData acquisition

The invention discloses a high-precision tube or an effective tube or hole diameter in a hole and an intelligent measuring device for the circle center thereof. It includes elastic centralizer, bracket, CCD vertical coordinate instrument, low-power data acquisition instrument, liquid storage tank, floating bucket, line body and controller; one end of the line body is connected with the elastic centerer, and the other end passes through the CCD The vertical line coordinate instrument, bracket, liquid storage tank, and floating bucket are connected to the controller; the controller is located in the floating bucket; the CCD vertical line coordinate instrument and the liquid storage tank are respectively set on the support; the low-power data acquisition instrument and the CCD vertical line The coordinate instrument is connected; the liquid is located in the liquid storage barrel; the floating barrel is suspended in the liquid storage barrel; the low-power data acquisition instrument and the controller are respectively connected with the industrial computer. The invention has the advantages of high degree of automation, greatly reducing labor intensity and improving measurement accuracy. The invention also discloses a measuring method of the high-precision tube or the effective tube or hole diameter in the hole and its circle center intelligent measuring device.

Owner:长江空间信息技术工程有限公司(武汉)

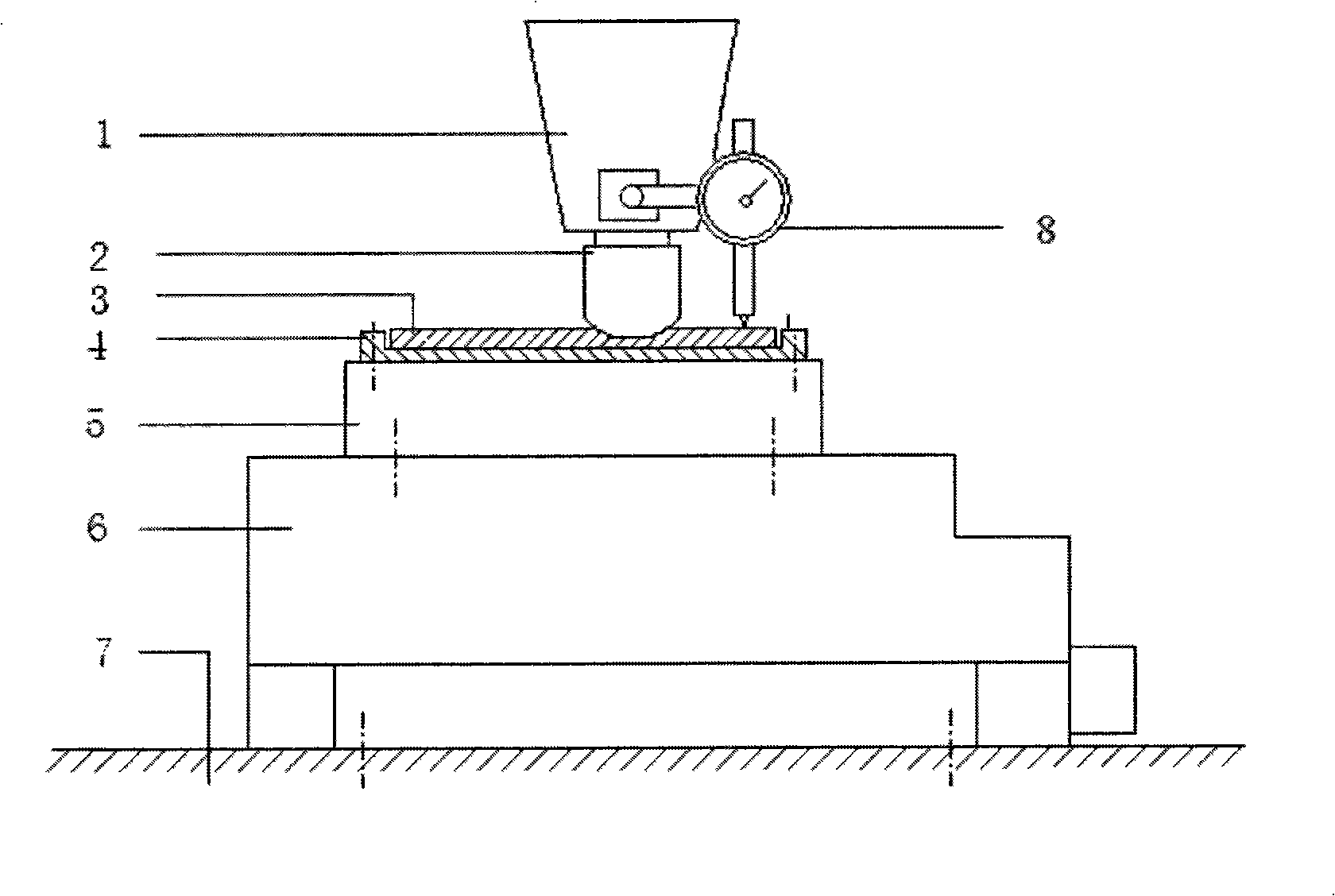

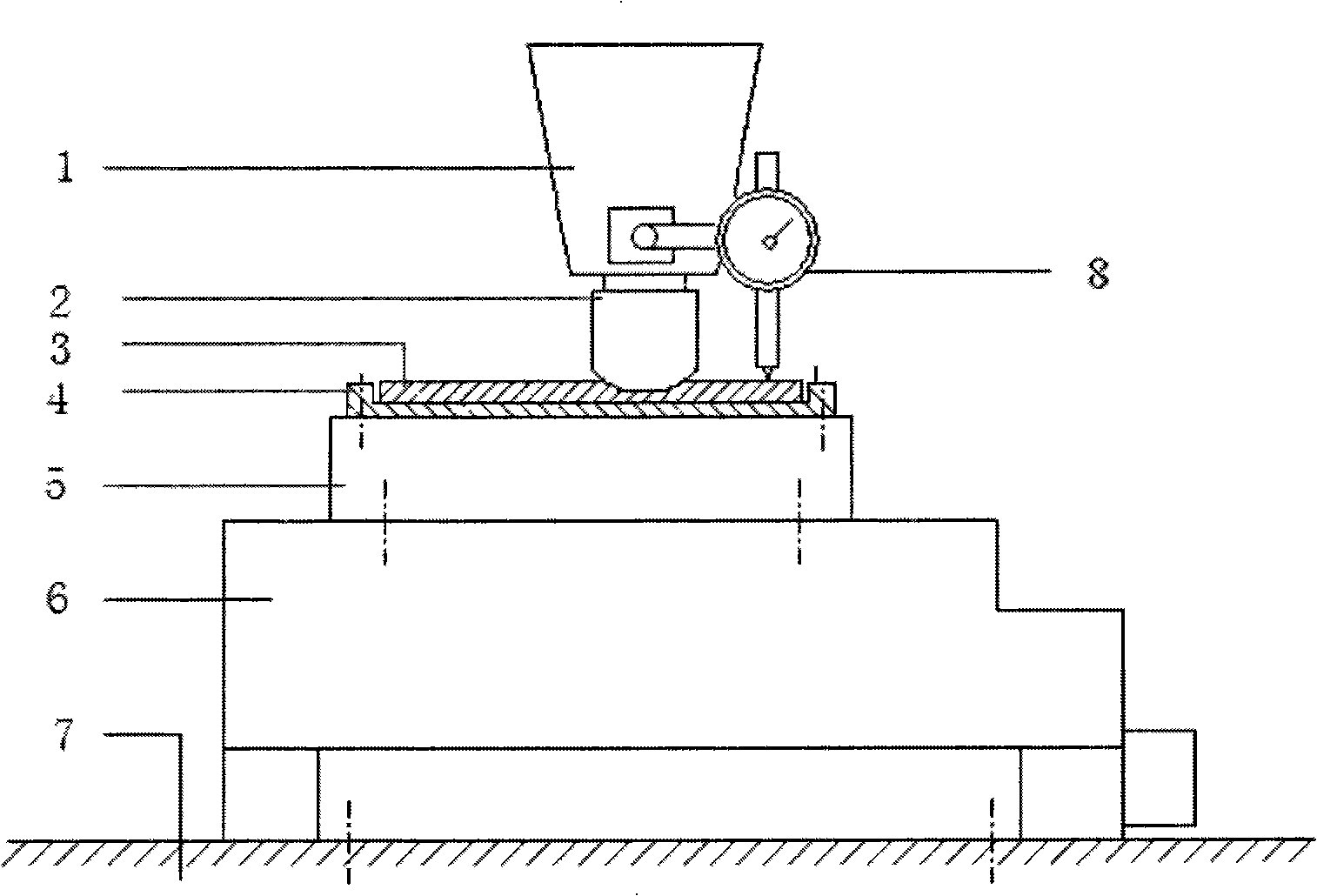

Internal surface tooth geometrical shape change measuring apparatus for rifled pipe expansion

InactiveCN101504284BReduce mistakesImprove heat transfer performanceMeasurement devicesMeasurement deviceShape change

The invention relates to a device for measuring the geometrical change of the tooth shape of the internal surface during the deformation of an internal screw tube expanding tube in the technical field of material processing, wherein a test piece is adhered to the inside of a test piece bonding groove which is fixed on a bonding groove fixed platform; the bonding groove fixed platform is fixed on a three-phase dynamometer piezoelectric transducer platform which is fixed on a three-dimensional coordinatograph working platform and connected with a charge amplifier and an A / D acquisition computerthrough a signal line; an expanding tube die is tightly fixed on a three-dimensional coordinatograph shank and locks the rotation freedom degree of the three-dimensional coordinatograph shank; and a dial gauge is fixed on the three-dimensional coordinatograph shank through a magnet base. The device evaluates the change of geometrical parameters of the designed tooth shape after the formation of the expanding tube in the design stage, can reasonably correct the designed tooth shape by a reverse design method, reduces the error of the designed tooth shape and an actual tooth shape, and has stable measuring result and high precision.

Owner:无锡凯博易机电科技有限公司

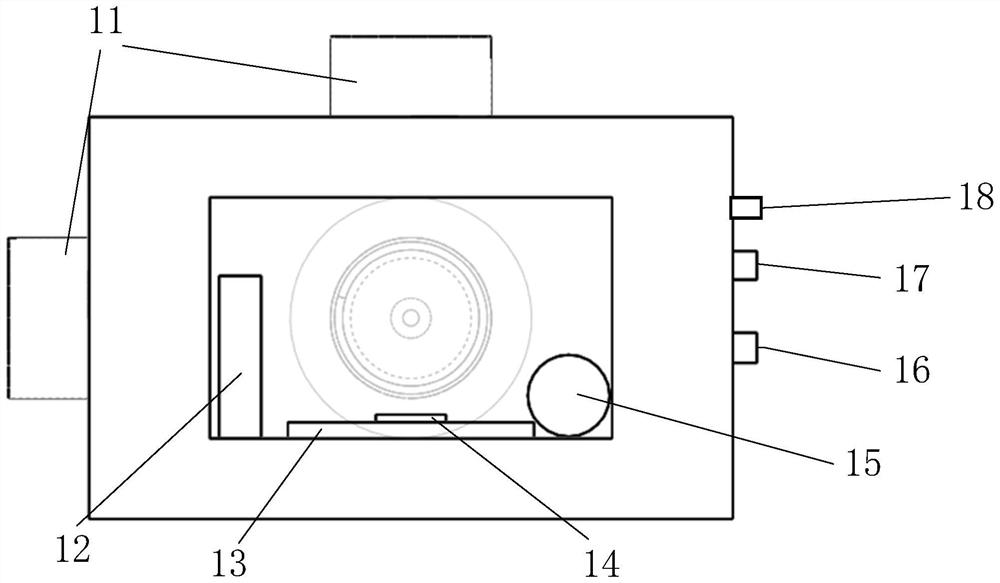

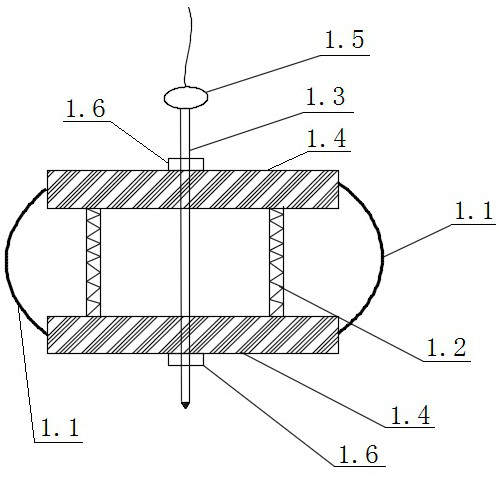

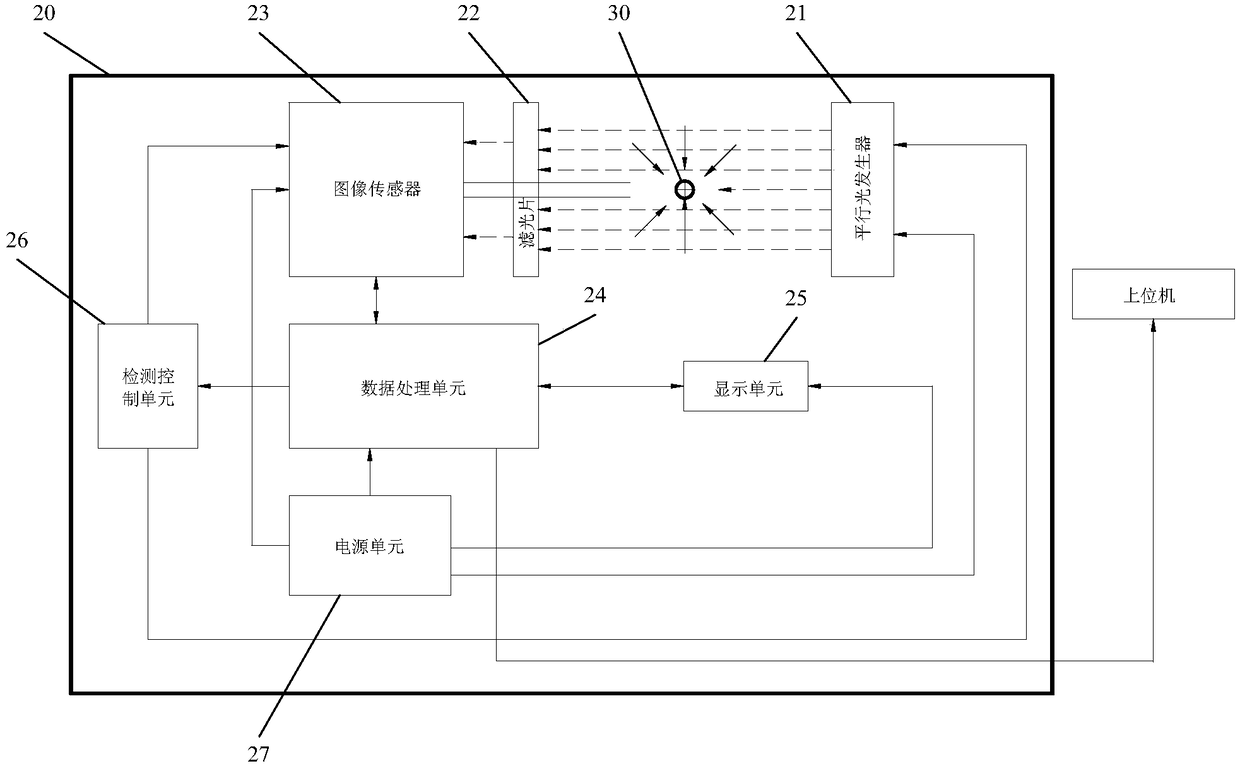

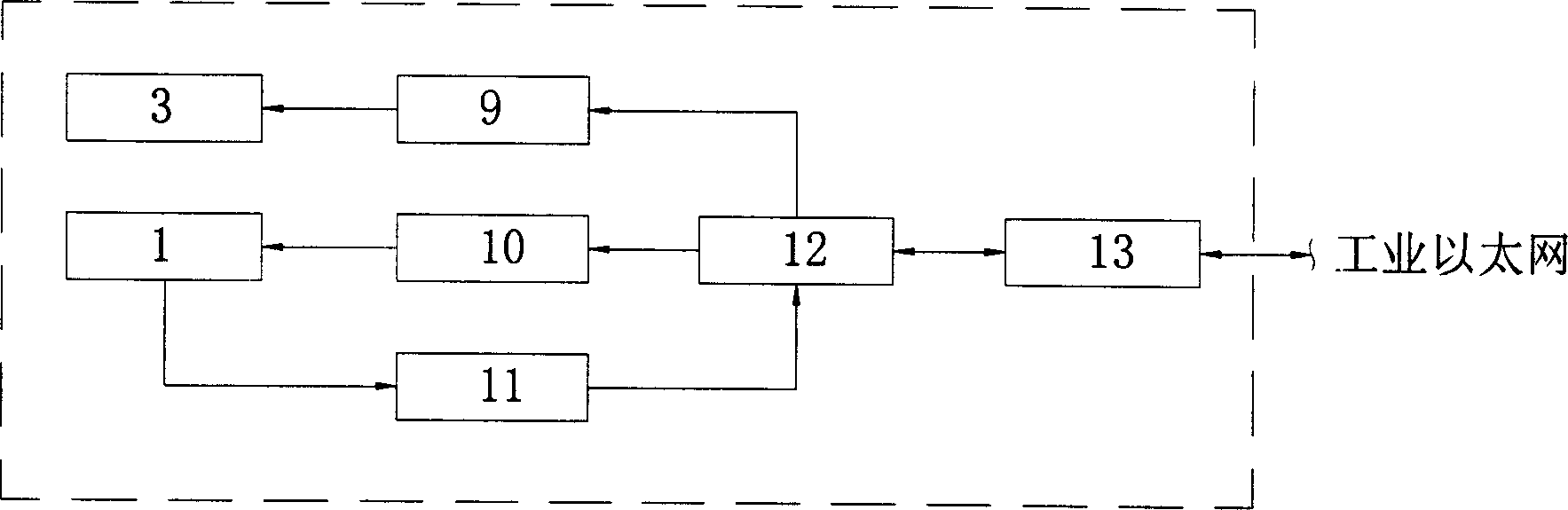

Pendulum coordinatograph

PendingCN108124351AControl light decayExtend your lifeElectrical apparatusElectroluminescent light sourcesCoordinatographVoltage reference

The invention provides a pendulum coordinatograph using a constant current driving circuit of a light emitting diode. The pendulum coordinatograph comprises a parallel light generator, a light filter,an image sensor, a data processing unit, a display unit, a detection control unit and a power supply unit, wherein the parallel light generator comprises an LED (light emitting diode) light source; the LED light source is driven by the constant current driving circuit of the light emitting diode; and the constant current driving circuit of the light emitting diode comprises a reference voltage source VR1, dual operational amplifier U1, a resistor R1, a resistor R2, a dual operational amplifier U2, a capacitor C1, an MOS (metal oxide semiconductor) field effect switch / power amplifier tube Q1,a silicon NPN tube Q2, a resistor R3, an adjustable resistor R0 and a light emitting diode D1. According to the coordinatograph, the constant current driving circuit can be used for driving the lightemitting diode in the pendulum coordinatograph; the damage of the LED light source caused by excessive current is avoided; and the problem of the damage to the LED light source of the pendulum coordinatograph due to heavy current is solved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Automatic fort 3D stereoscopic model special for teenager science popularization teaching

The invention discloses an automatic fort 3D stereoscopic model special for teenager science popularization teaching. The model comprises a gun barrel, a remote shooting coordinatograph, a fixing member, a pressure chamber, a barrel revolver, an internal gear external gear sleeve unit, an external ring wheel internal gear sleeve unit, a main shaft connector, a motor main shaft, a motor, a chassis, a control case, a numerical control line, simulation model shells, a simulation model magazine, a pushing chamber, a modelling loader and a remote shooting coordinate controller. Compared with a conventional science popularization teaching tool having a single function, the automatic fort 3D stereoscopic model science popularization teaching tool model is specially used for national defense science popularization education which is developed for teenagers and with national defense education being the theme, has a lifelike shape, is safe to use, is novel and peculiar, has practical and profound education significance on inspiring innovation thoughts of the teenagers and creatively developing researches on various military automatic forts, and is a miracle in military models.

Owner:FOSHAN SANSHUI DISTRICT XIWANG HUOJU EDUCATIONAL TECH CO LTD

Automatic ultrasonic detection system of non-contact solid geologic model

ActiveCN102818841BRealistic simulation effectLarge dynamic rangeAnalysing solids using sonic/ultrasonic/infrasonic wavesSeismologyCoordinatographHigh voltage pulse

The invention provides an automatic ultrasonic detection system of a non-contact solid geologic model and belongs to the field of ultrasonic vibrating detection. The automatic ultrasonic detection system comprises an emitting device, a receiving device, a high-speed analog-to-digital converter and a three-dimensional coordinatograph platform. A detected geologic model, the emitting device and the receiving device are all arranged on the three-dimensional coordinatograph platform. The high-speed analog-to-digital converter processes signals collected by the receiving device and then transmits the signals to a computer. The emitting device comprises a high-voltage pulse generator and a non-contact focusing probe. The automatic ultrasonic detection system solves the problem of various normal geologic model simulation systems, can perform large-scale multipoint non-contact ultrasonic detection for complex surface models and meets special requirements of modern geophysical prospecting fine simulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

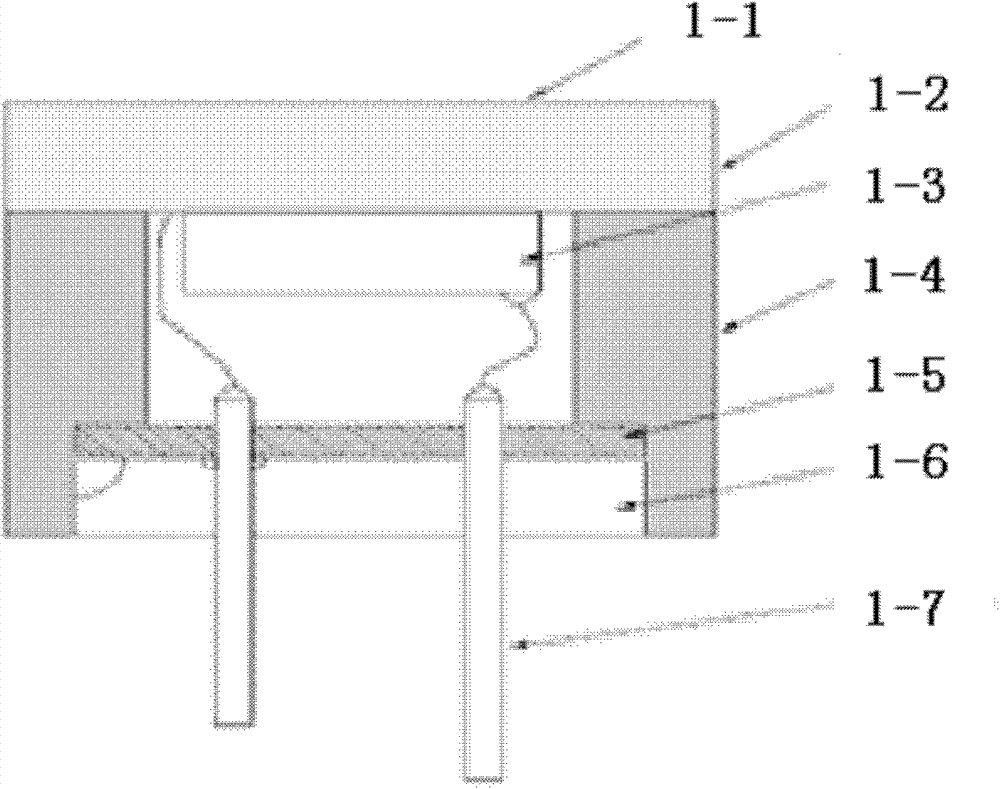

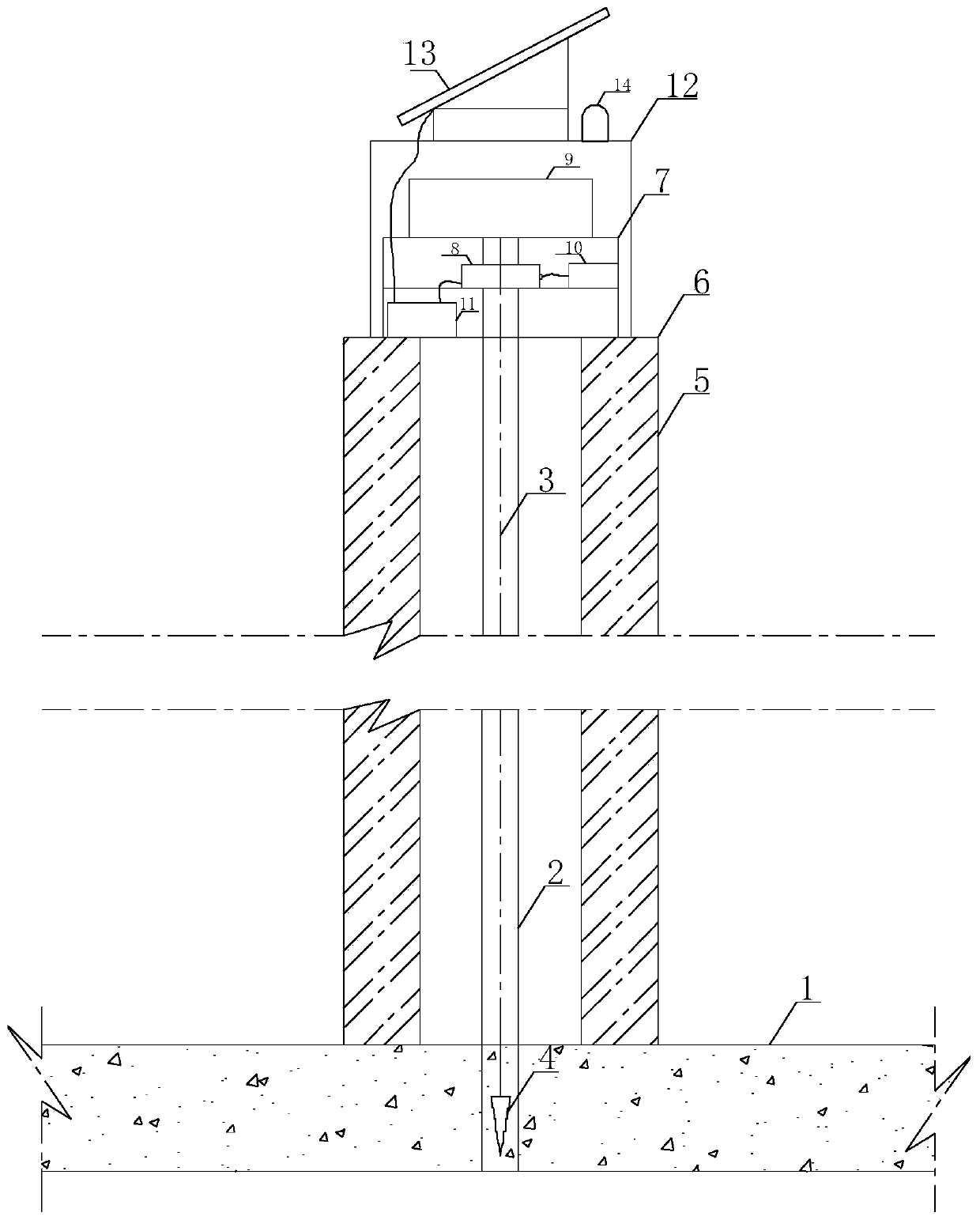

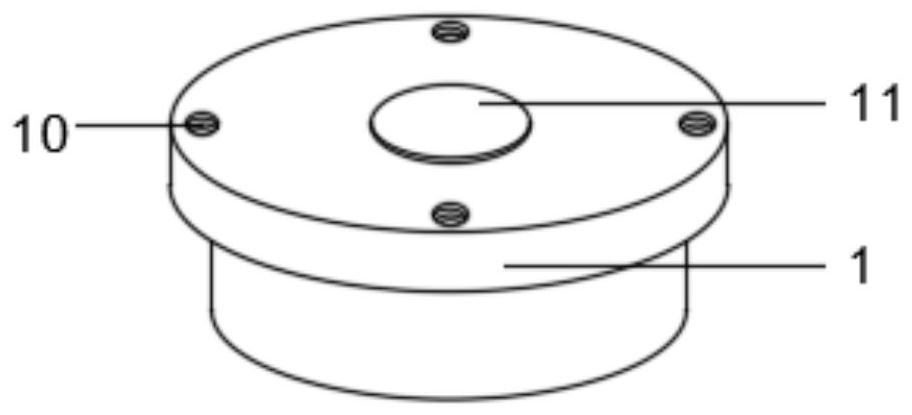

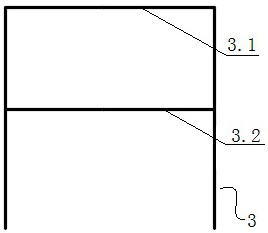

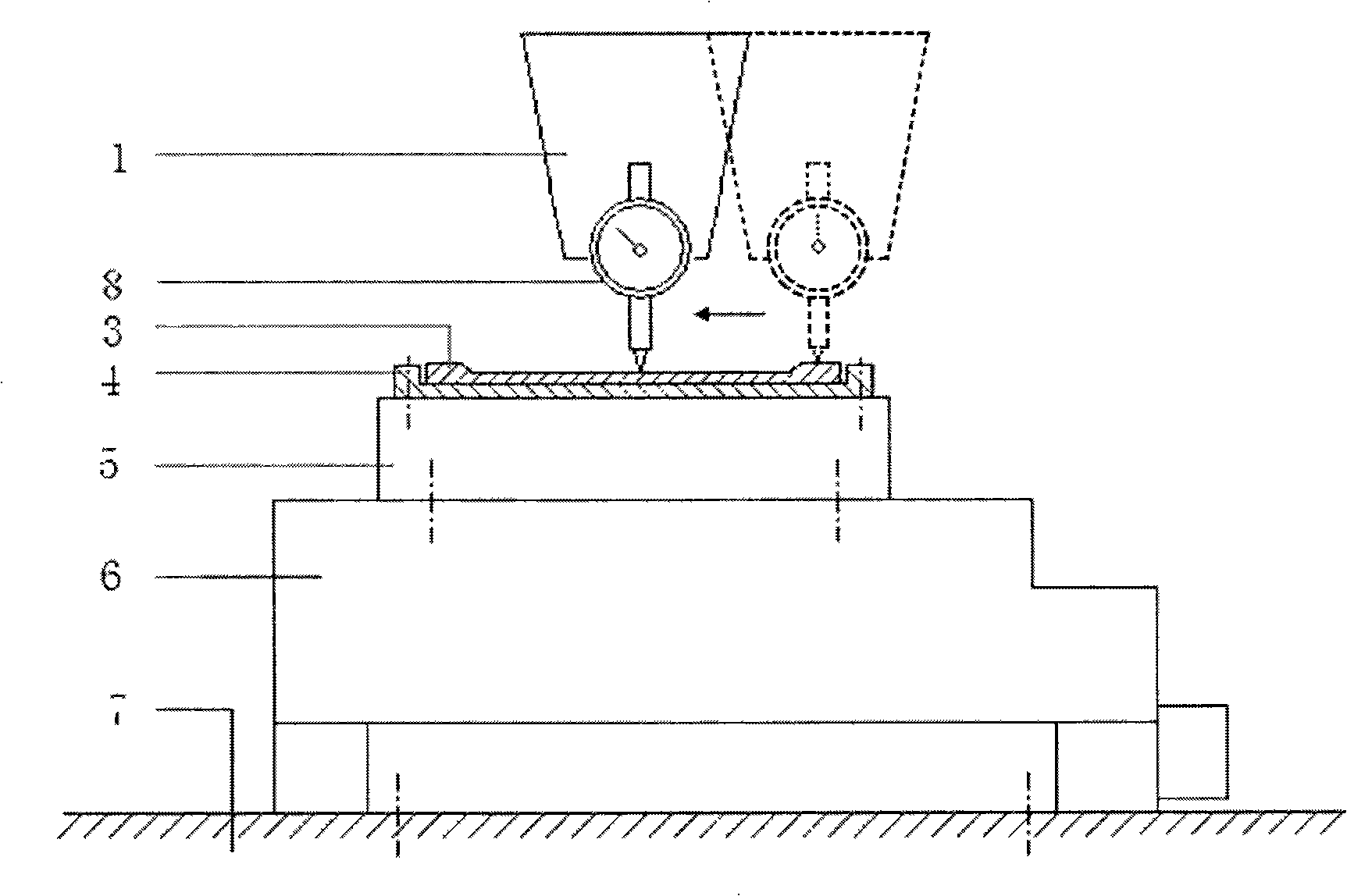

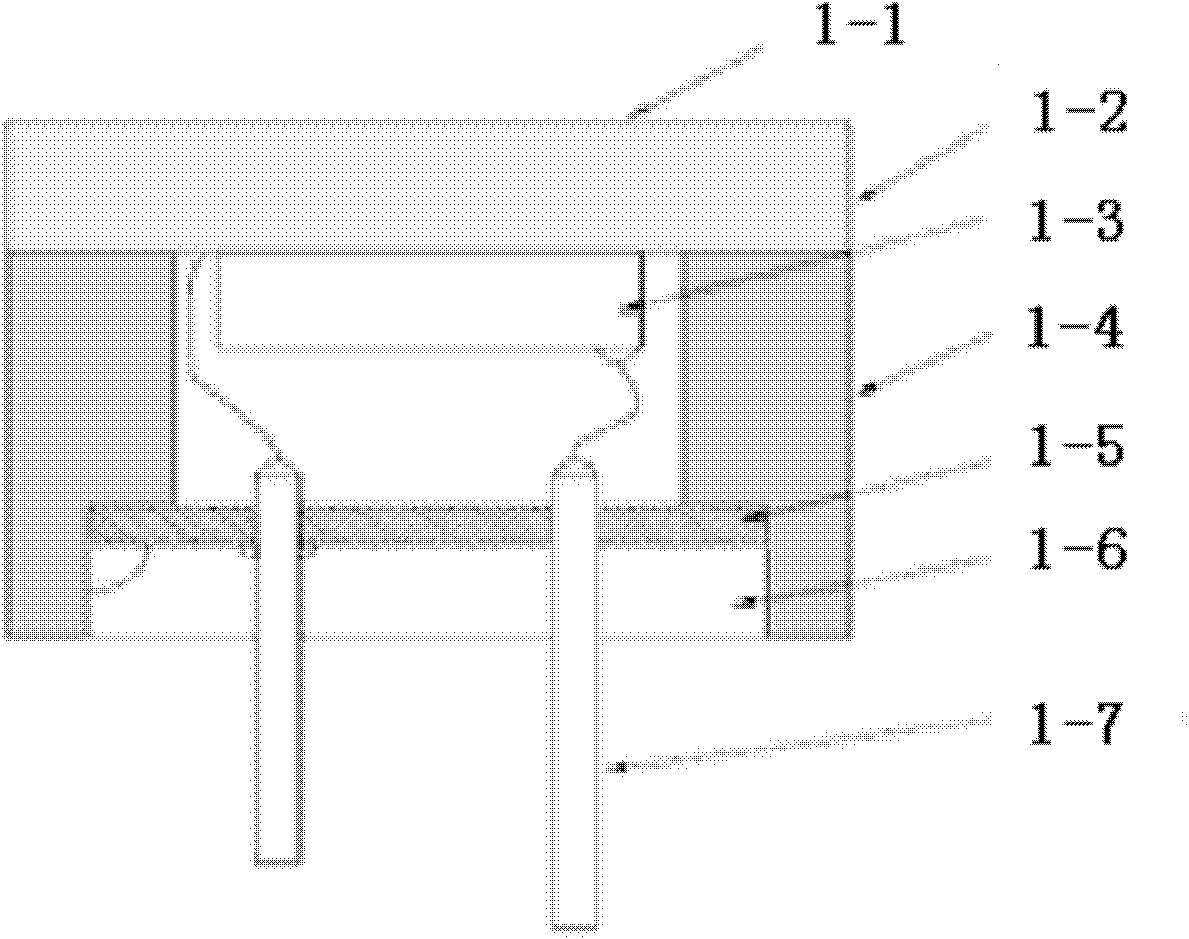

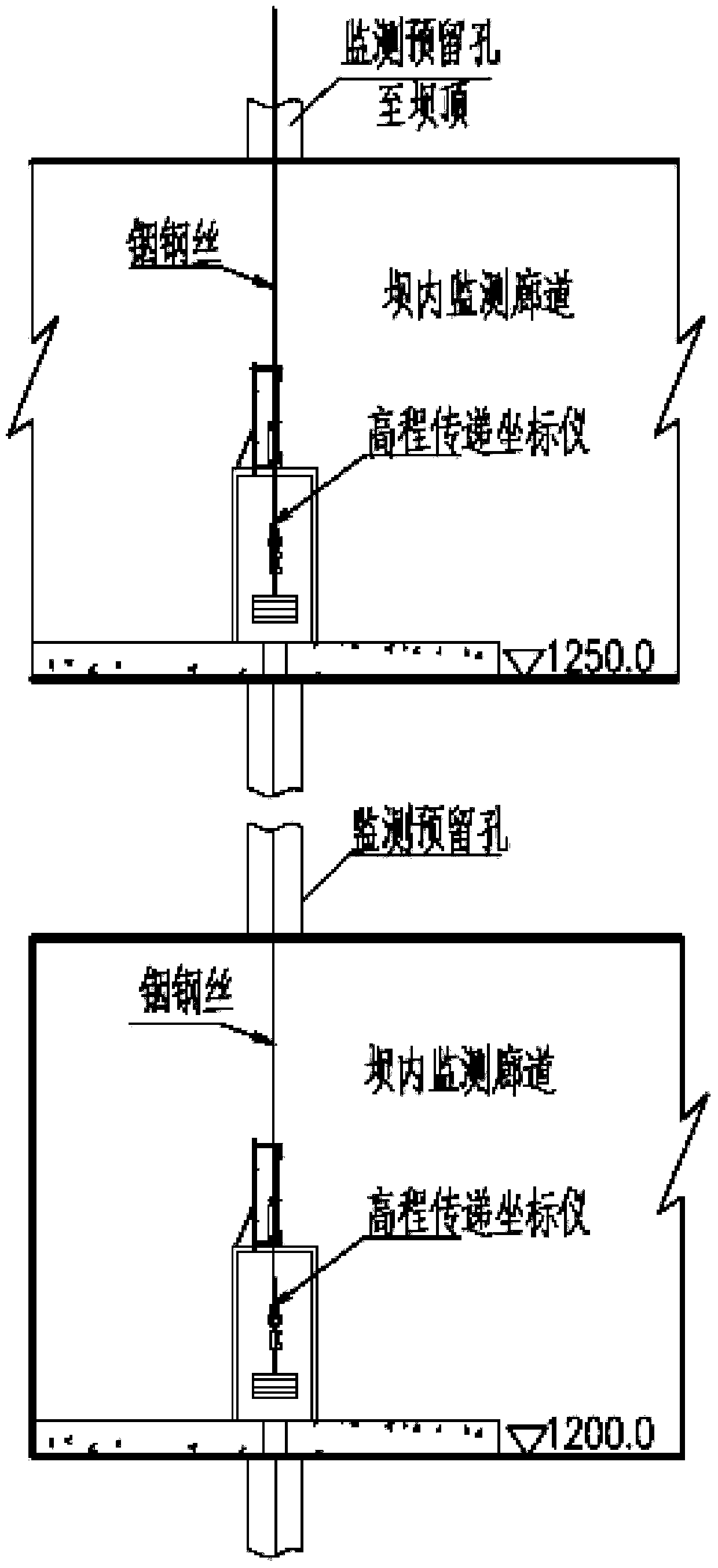

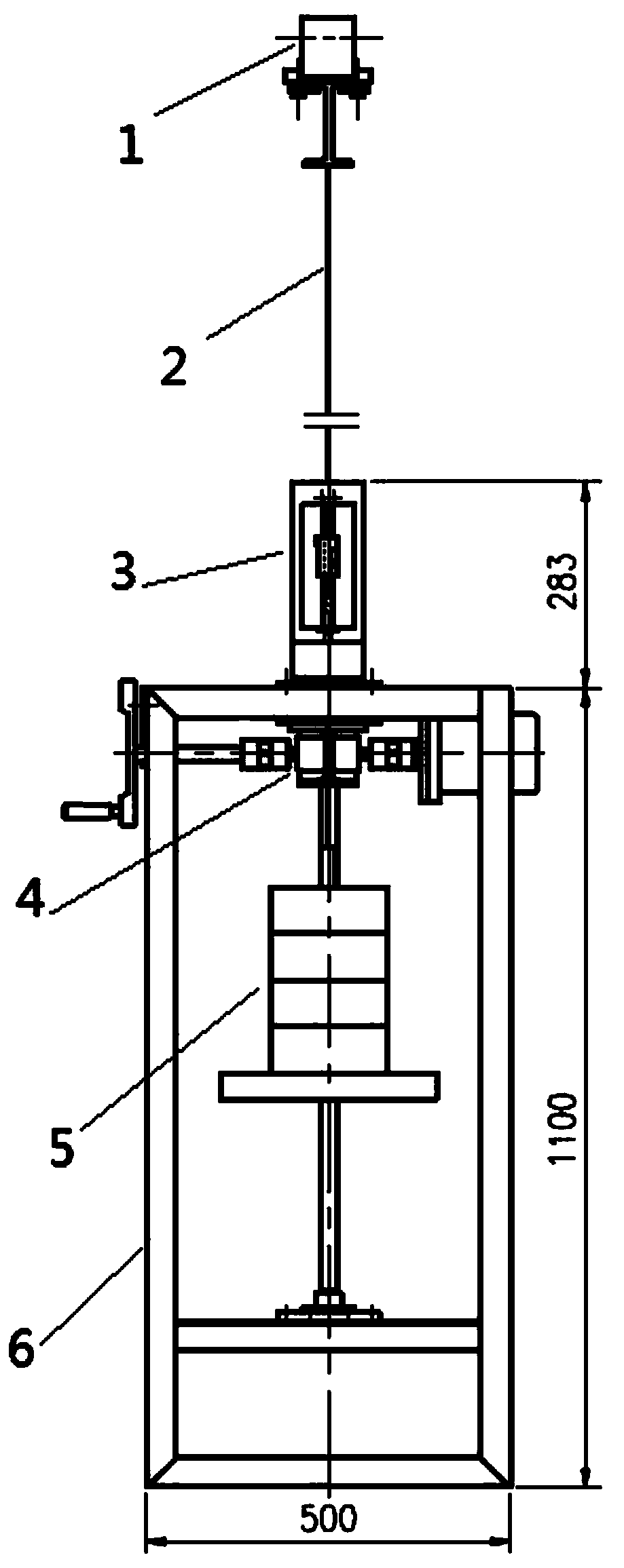

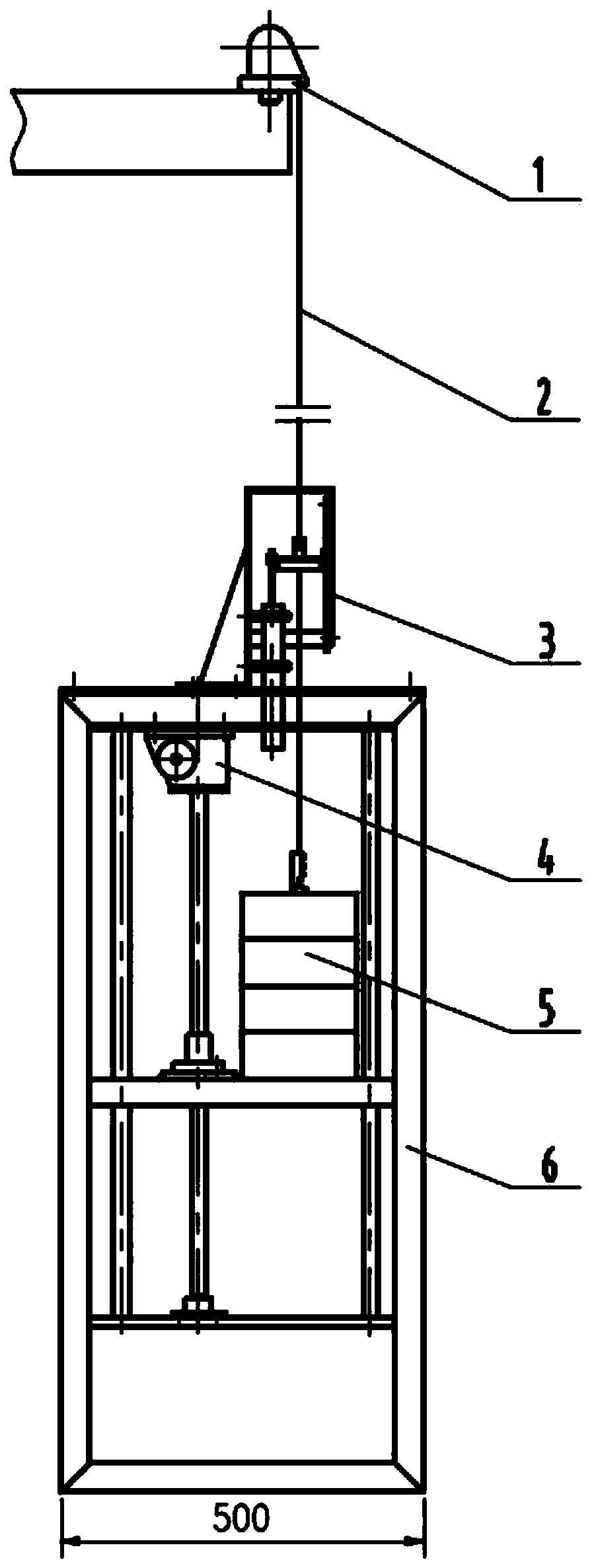

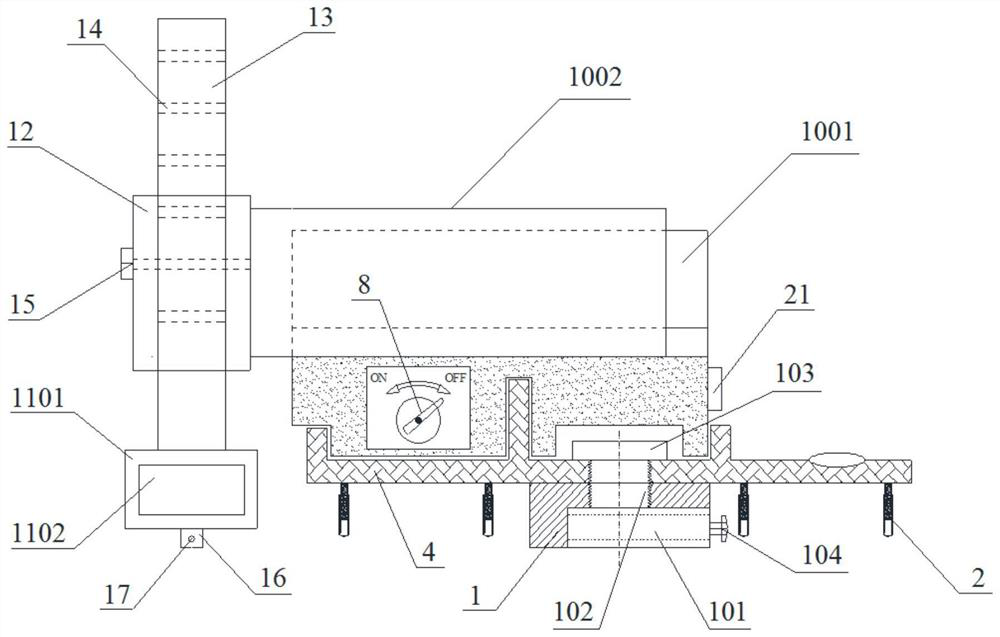

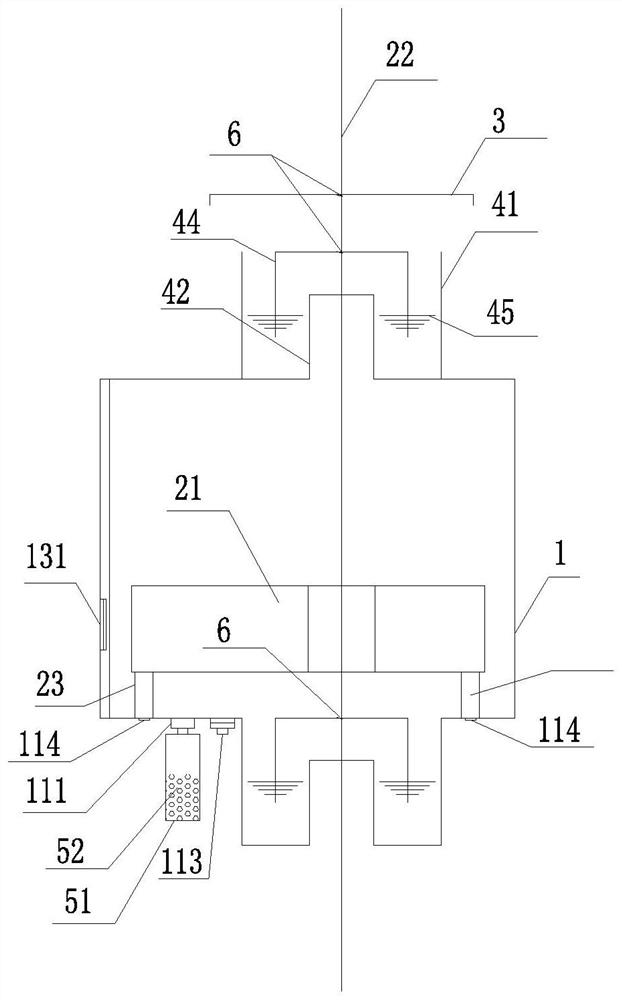

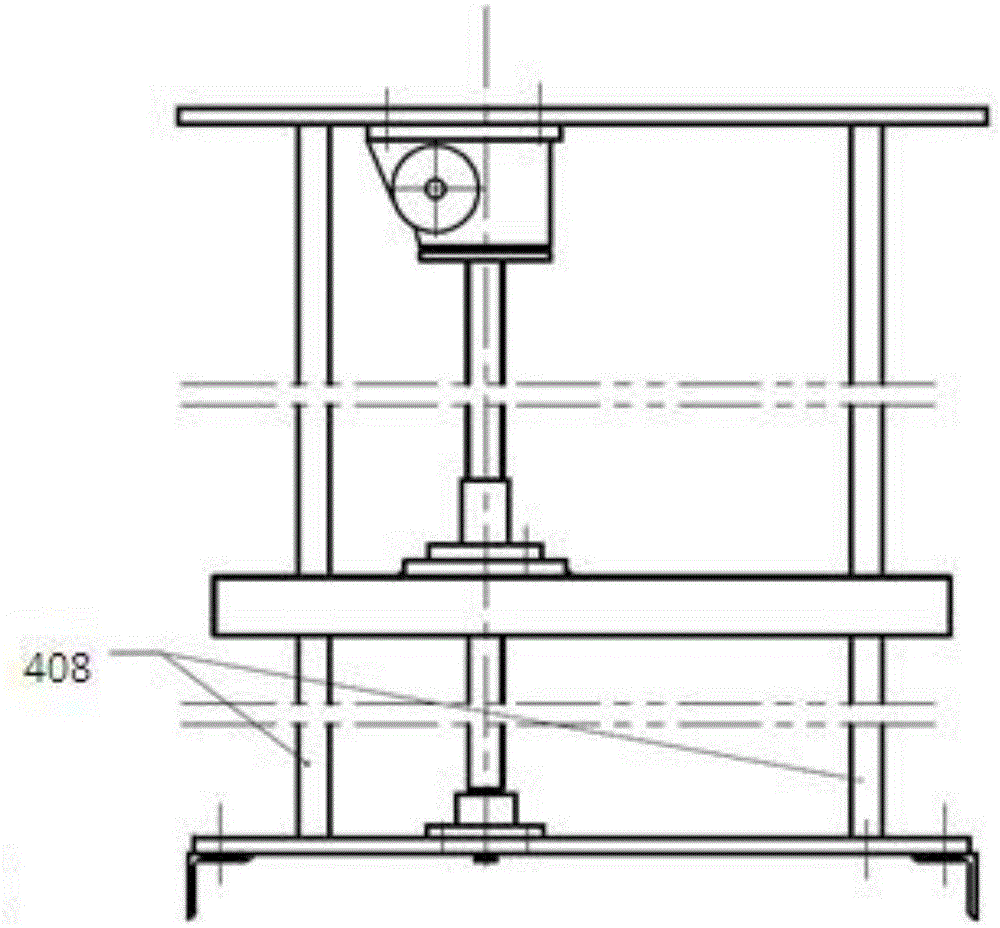

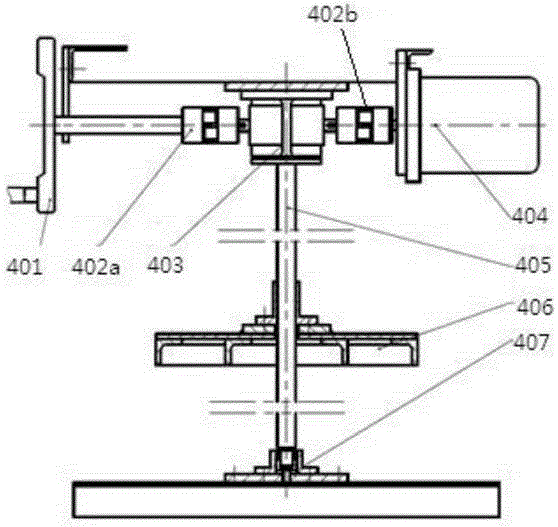

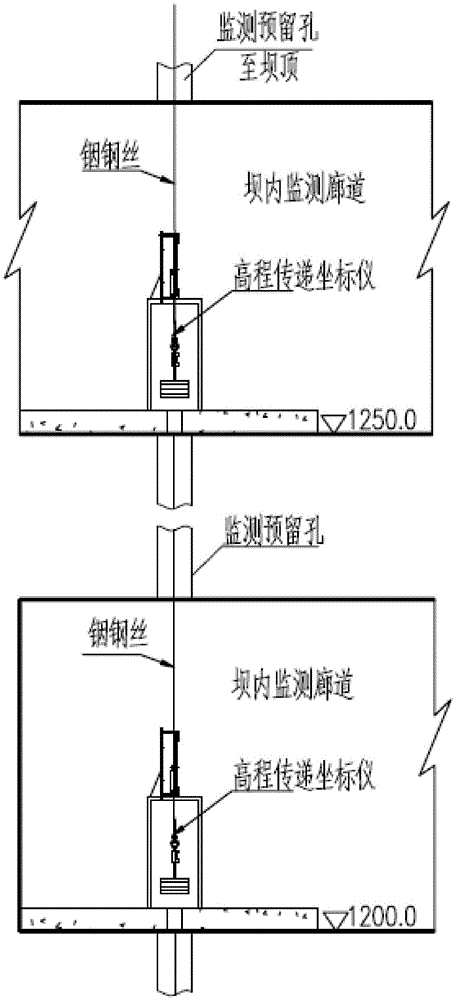

Automatic elevation transmission coordinatograph

ActiveCN104121887AAvoid getting stuckHigh measurement accuracyHeight/levelling measurementAutomatic controlStructural engineering

The invention relates to an automatic elevation transmission coordinatograph. The coordinatograph comprises a wire-hanging part (1), a stay wire (2), a reading part (3), an elevating part (4), a counterweight part (5), and a rack part (6); the top end of the stay wire (2) is connected to the wire-hanging part (1), the stay wire (2) goes through the reading part (3) and enters into the rack part (6), the bottom end of the stay wire (2) is connected to the counterweight part (5); the reading part (3) is arranged on the rack part (6), the elevating part (4) is arranged in the rack part (6); the elevating part (4) comprises a tray (406), and the counterweight part (5) is arranged above the tray (406). The coordinatograph achieves automatic control and measurement, and the measurement precision is high.

Owner:NARI TECH CO LTD +1

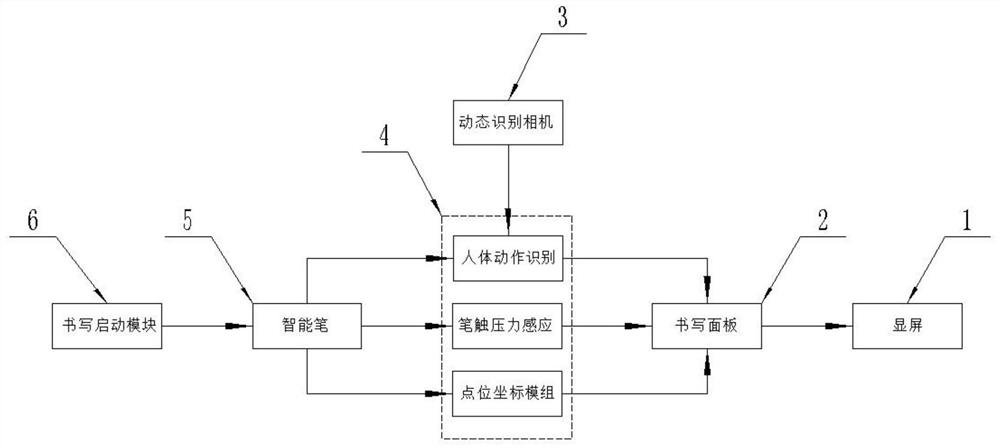

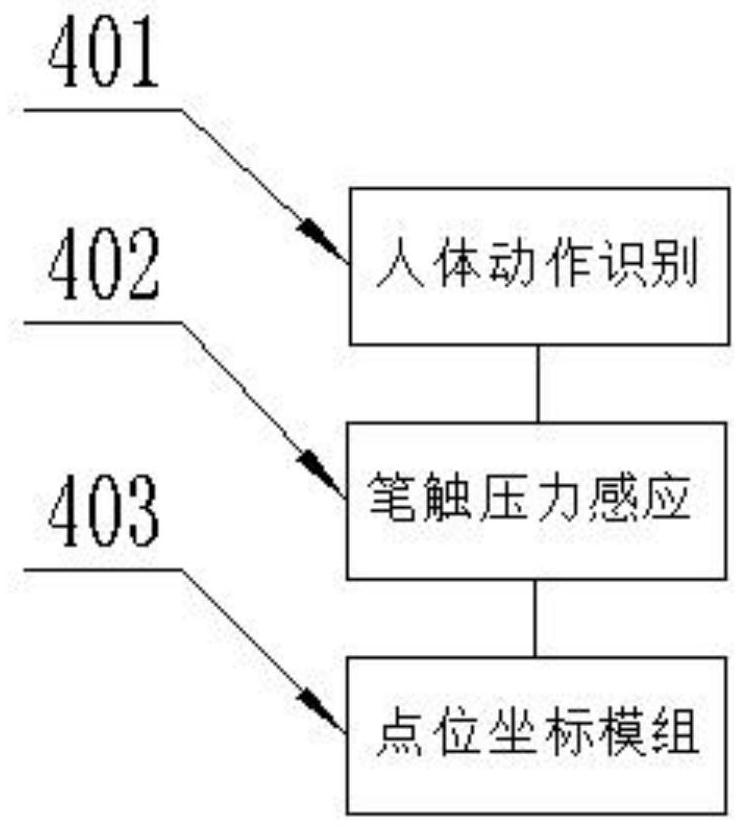

Writing starting system based on intelligent pen operation

PendingCN112947779APrevent broken penPrevent accidental writingInput/output processes for data processingComputer hardwareCoordinatograph

A writing starting system based on intelligent pen operation relates to a starting system and comprises a display screen, the input end of the display screen is provided with the output end of a writing panel, the input end of the writing panel is provided with the output end of an execution signal element, and the input end of the execution signal element is provided with the output end of a dynamic recognition camera. The other input end of the execution signal element is provided with the output end of the intelligent pen, and the input end of the intelligent pen is provided with a writing starting module. By means of the device, the holding area is arranged, and the device is suitable for users with different writing and holding habits in combination with a touch switch signal; the coordinatograph is arranged, so that the pen breaking phenomenon during writing or the mistaken touch writing phenomenon caused by the wrong holding mode can be prevented; and the intelligent pen is provided with an execution element, and writing trigger signals of the intelligent pen are complemented or detected through human body action recognition, pen touch pressure induction and point position coordinate signals in combination with actual use conditions.

Owner:广州宏途数字科技有限公司

Optical coordinatograph possessing remote maintenance function

InactiveCN1546949AImprove reliabilityIncrease redundancyPlumb lines for surveyingCoordinatographDistributed testing

The invention is a kind of optical coordinate apparatus which has remote maintaining function. The connection between the sensor light path and the sensor circuit is realized through connecting the charge coupler array and LED illuminant diode array in the sensor light path and the relative charge coupler array driving circuit and LED illuminant diode array driving circuit in the sensor circuit, the charge coupler array in the sensor light path is connected with the signal processing and project collecting circuit in the sensor circuit; there sets a measuring range for the sensor light path, one side of it sets a charge coupler array, the other side sets a LED illuminant diode array; the sensor circuit has a driving circuit and a microprocessor, signal processing and project collecting circuit, a network communication model for providing remote test analysis and diagnosis functions. The measured data has a big redundancy; the invention carries on analysis, diagnosis, and maintenances according to the sensor data, and upgrades the reliability working in mal-condition.

Owner:HOHAI UNIV

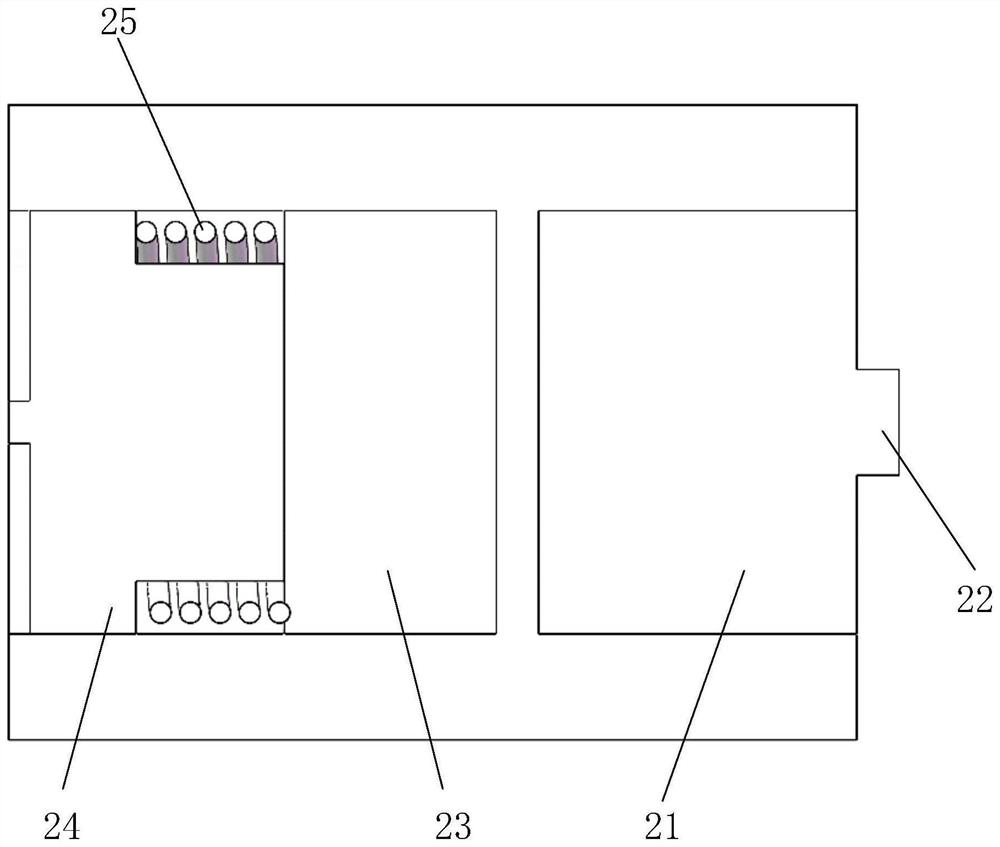

Automatic device and method for verifying accuracy of vertical line system

PendingCN114858042AEnsure consistencyOvercome the disadvantage of poor stabilityActive open surveying meansTotal factory controlElectric machineControl engineering

The invention discloses an automation device and method for verifying the accuracy of a vertical line system, and the device comprises a working platen, the working platen is disposed on a vertical line coordinatograph, the working platen is provided with a guide groove, the guide groove is internally provided with a sliding block, the sliding block is provided with a motor I, the end part of the motor I is provided with a strip-shaped measuring rod, and the lower part of the strip-shaped measuring rod is provided with a motor II. A laser is arranged at the bottom of the motor II, and an H-shaped wire contact mechanism is arranged at the end of the motor II and works cooperatively with the motor I and the motor II, so that accurate displacement is given to the vertical line in the verification process. The working platen can be horizontally and stably placed at any position, the laser can be adopted for precise orientation, the consistency of the moving direction and the plumb line coordinatograph is guaranteed, the linear motor is adopted for eliminating positioning errors, the H-shaped line contact mechanism is adopted for guaranteeing zero disturbance of the initial value of a plumb line, the overall structure is compact and small, applicability is high, and adjustment and control are easy. The working process is simple and clear, the working efficiency is improved, and automatic verification of the accuracy of the vertical line system is realized.

Owner:XIAN THERMAL POWER RES INST CO LTD +2

Damp-proof protective cover for plumb line coordinatograph

PendingCN114803066AIncreased durabilityImprove stabilitySealingContainers preventing decayStructural engineeringCoordinatograph

The invention discloses a moisture-proof protective cover for a plumb line coordinatograph, and relates to the field of deformation measurement. The device comprises a box body, an instrument system, a waterproof system, freely movable sealing systems and a drying system, the box body comprises a bottom plate, a top plate and four panels connected with the bottom plate and the top plate, and the freely movable sealing systems are arranged on the bottom plate and the top plate; the instrument system comprises a coordinatograph and a hanging steel wire; the free movable sealing system comprises a cylindrical container outer wall, a cylindrical container inner wall, a cylindrical container bottom plate and a cylindrical cover, and the drying system is installed on the bottom plate. The protection device adopts a physical isolation mode, does not need a power supply, only needs to replace a drying agent in real time, is simple to maintain and low in operation cost, is a simple, economical and practical protection device, can effectively solve the moisture-proof and anti-corrosion problems of the plumb line coordinatograph, and has a wide market prospect.

Owner:周雨梦

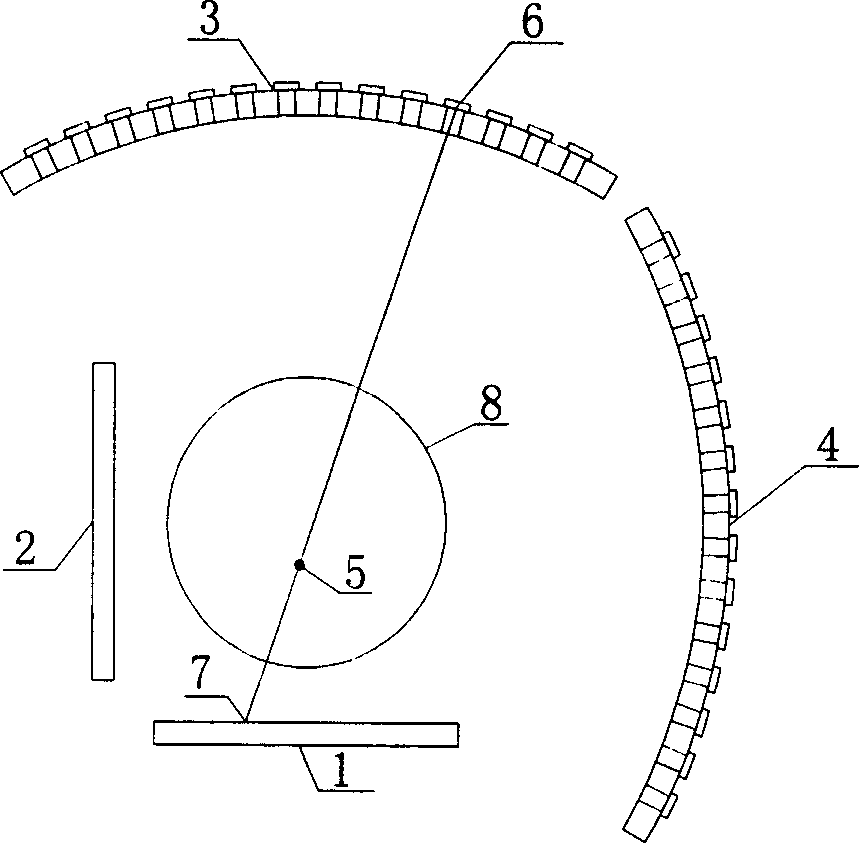

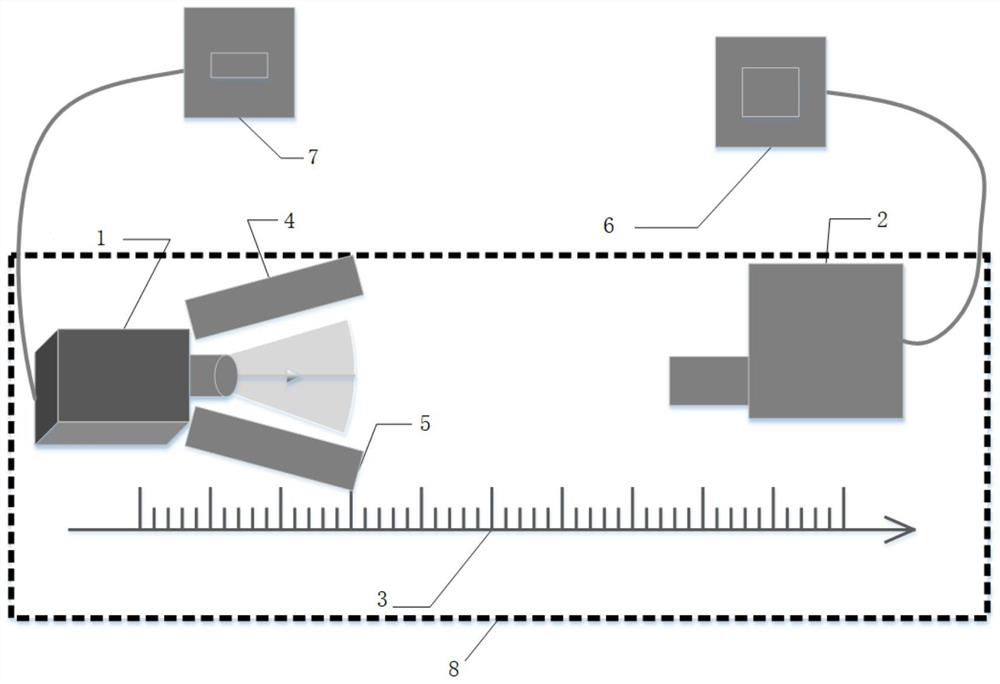

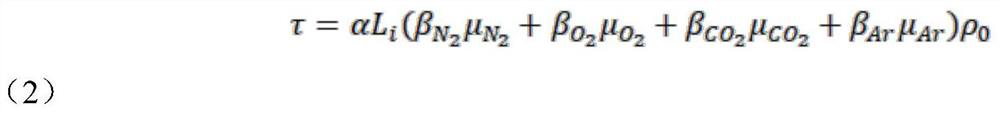

An Atmospheric Density Measurement System Based on X-ray Absorption

ActiveCN109827871BCompact structureEasy to operateSpecific gravity measurementQuantum efficiencyDivergence angle

The invention discloses an atmospheric density measurement system based on X-ray absorption, the system is located in a vacuum chamber (8), and the system includes: an X-ray source (1), an SDD detector (2), a high-precision coordinate instrument ( 3), the first X-ray shielding cover (4), the second X-ray shielding cover (5) and the controller and the data acquisition processing terminal (6); the SDD detector (2) is the same as the X-ray source (1) The axes are relatively placed; the X-ray source (1) is used to provide the X-ray light source required for measurement; the SDD detector (2) is used to receive X-ray energy spectrum counting, and perform energy calibration and quantum Efficiency calibration, dead time calibration, and divergence angle calibration to obtain calibrated X-ray energy spectrum counts; the controller and the data acquisition processing terminal (6) are used for counting and X-ray Poisson energy spectrum according to the calibrated X-ray energy spectrum Statistical maximum likelihood estimation, Bayesian estimation to obtain surface atmospheric density.

Owner:NAT SPACE SCI CENT CAS

An automatic elevation transmission coordinate instrument

ActiveCN104121887BAvoid getting stuckHigh measurement accuracyHeight/levelling measurementAutomatic controlEngineering

The invention relates to an automatic elevation transmission coordinatograph. The coordinatograph comprises a wire-hanging part (1), a stay wire (2), a reading part (3), an elevating part (4), a counterweight part (5), and a rack part (6); the top end of the stay wire (2) is connected to the wire-hanging part (1), the stay wire (2) goes through the reading part (3) and enters into the rack part (6), the bottom end of the stay wire (2) is connected to the counterweight part (5); the reading part (3) is arranged on the rack part (6), the elevating part (4) is arranged in the rack part (6); the elevating part (4) comprises a tray (406), and the counterweight part (5) is arranged above the tray (406). The coordinatograph achieves automatic control and measurement, and the measurement precision is high.

Owner:NARI TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com