Buckle tower deviation monitoring device

A monitoring device and offset technology, applied in measuring devices, mapping and navigation, measuring inclination, etc., can solve the problems of inability to reflect the torsion of the buckle tower, certain deviations in the results, wire swing or jitter, etc., to meet real-time monitoring requirements. The effect of reducing demand, manpower input, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

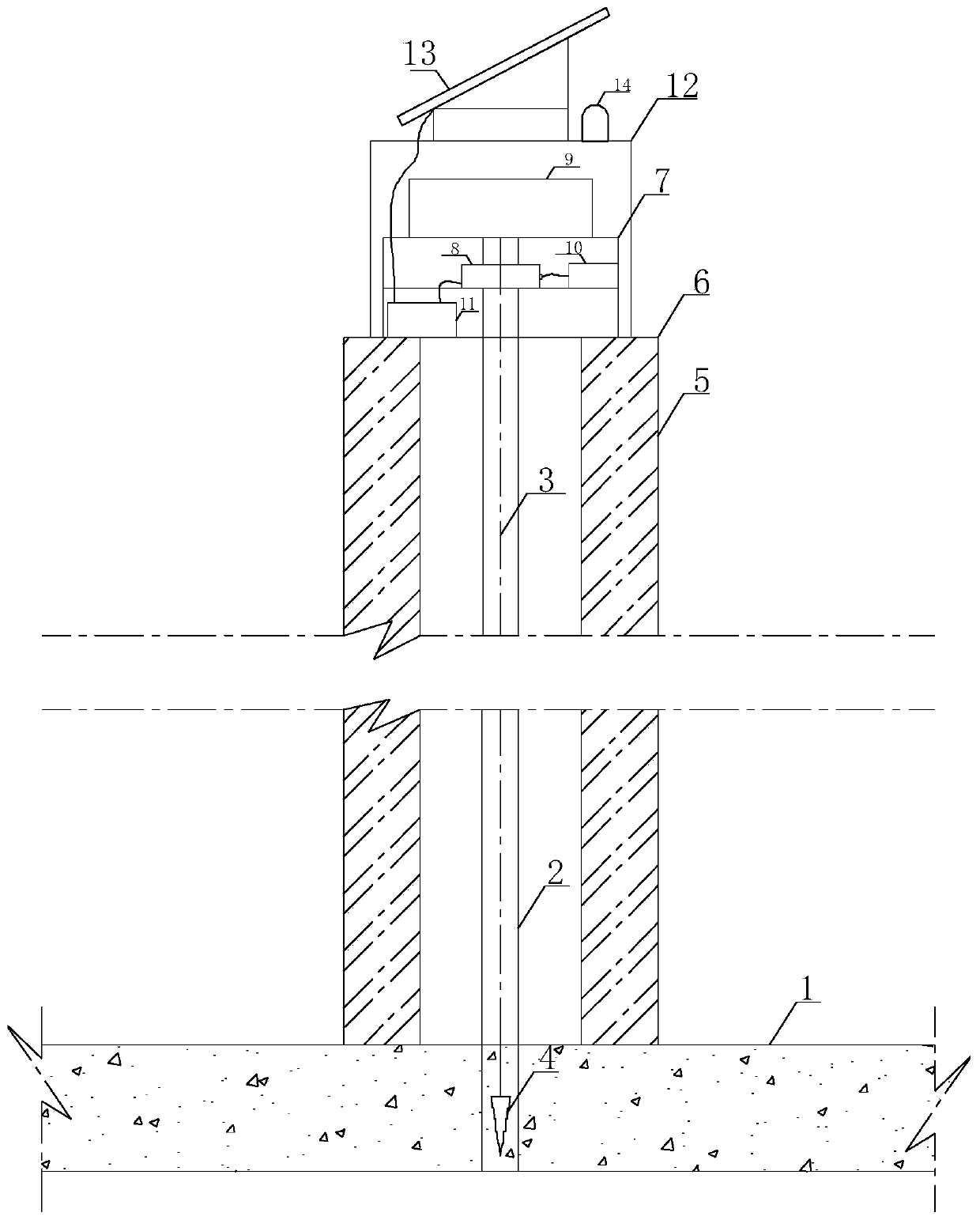

[0025] like figure 1 A kind of buckle deflection monitoring device shown, comprises the buckle pillar 5 vertically on the base 1; Indium steel wire 3 is arranged on the axis line of buckle pillar 5, and coordinate instrument 8 is fixed on the top of buckle pillar 5 A buoy 9 is fixed above the coordinate instrument 8, the top of the indium steel wire 3 is connected to the bottom of the buoy 9, and the indium steel wire 3 passes through the coordinate instrument 8 vertically downward; the coordinate instrument 8 is electrically connected to the battery 11.

[0026] Buckle tower pillar 5 tops are fixed with base plate 6 flatly, also be fixed with protective cover 12 to form closed space on the base plate 6, coordinate instrument 8, buoy 9, storage battery 11 are all fixed in protective cover 12.

[0027] There is a mounting bracket 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com