Internal surface tooth geometrical shape change measuring apparatus for rifled pipe expansion

A technology of geometric shape and measuring device, which is applied in the field of measuring device for the geometric shape change of the inner surface tooth shape in the forming of internally threaded pipe expansion, can solve the problems such as the inability to effectively obtain the change of tooth height, and achieve simple structure, good rigidity, and good results Precise and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

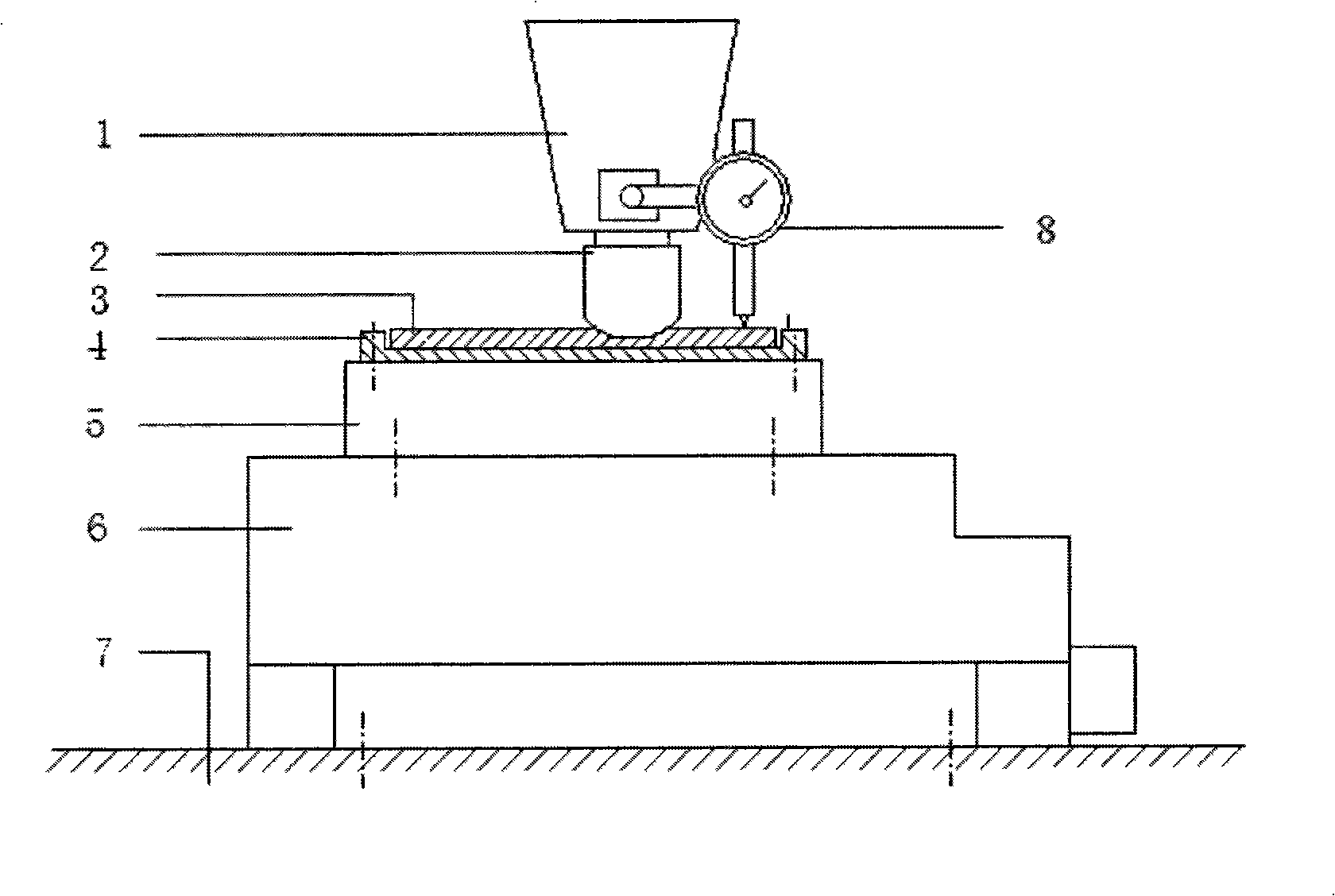

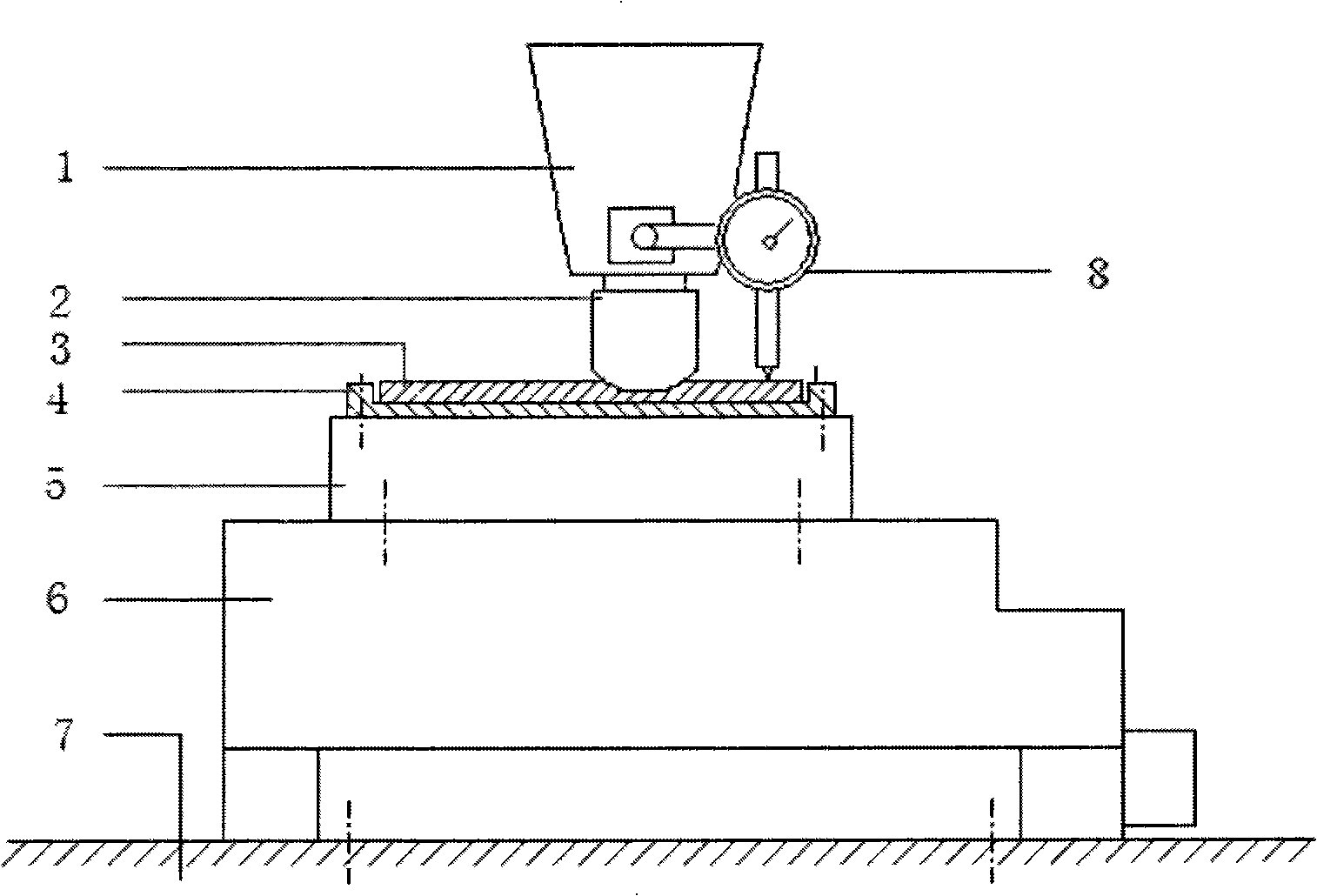

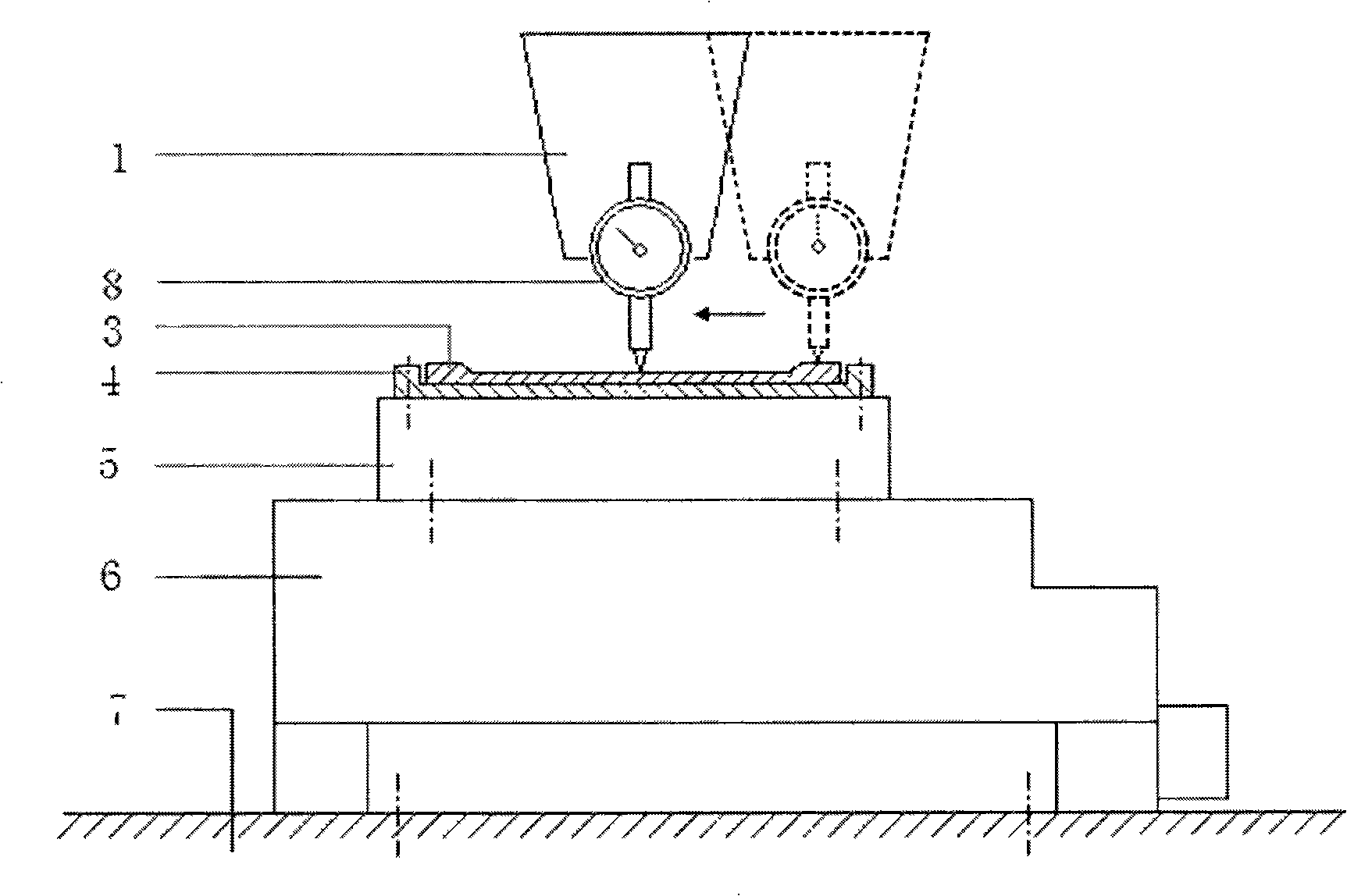

[0017] As shown in Figure 1-2, this embodiment includes: three-dimensional coordinate instrument handle 1, expansion tube mold 2, test piece 3, test piece bonding groove 4, bonding groove fixing table 5, three-phase dynamic instrument piezoelectric sensor Platform 6, three-dimensional coordinate instrument workbench 7, dial indicator 8. The piezoelectric sensor platform 6 of the three-phase dynamic instrument is fixed on the three-dimensional coordinate instrument workbench 7 through bolt connection, and is connected to the charge amplifier and the A / D acquisition computer through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com