A strip of a contactless large chip smart card

A large chip and smart card technology, which is applied to recording carriers, instruments, and electrical components used in machines, can solve problems such as poor tensile strength, cumbersome processes, and increased costs, and achieve the effect of maximizing area utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] see Figure 3 to Figure 10 , the inventor of the present invention, in order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments and in conjunction with the accompanying drawings.

[0026] 1. The first embodiment

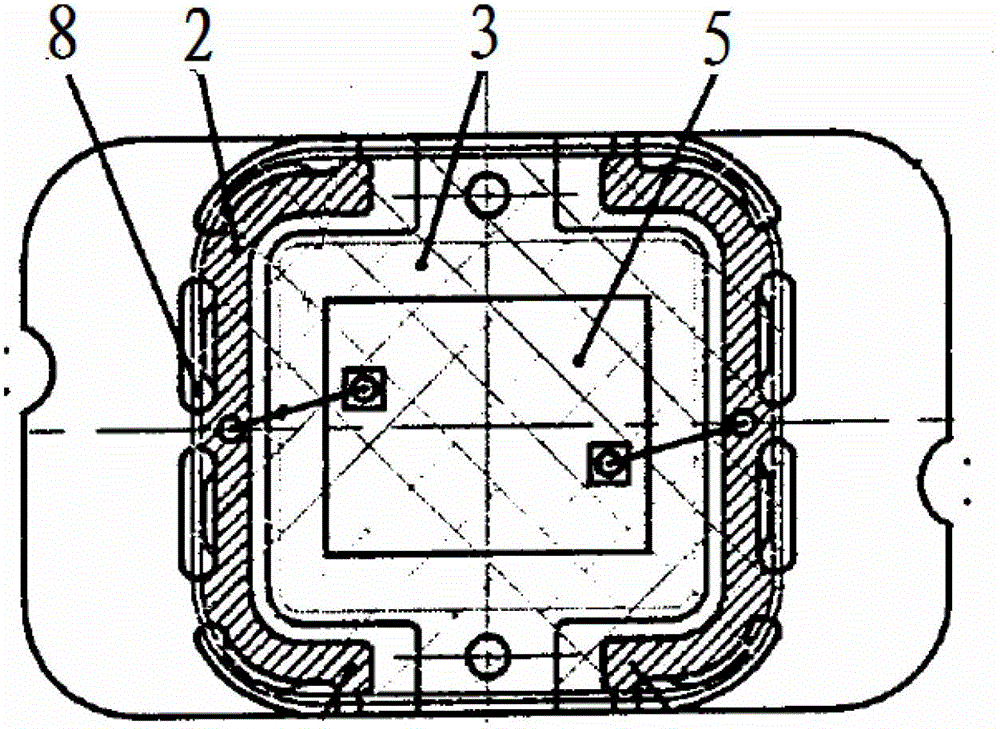

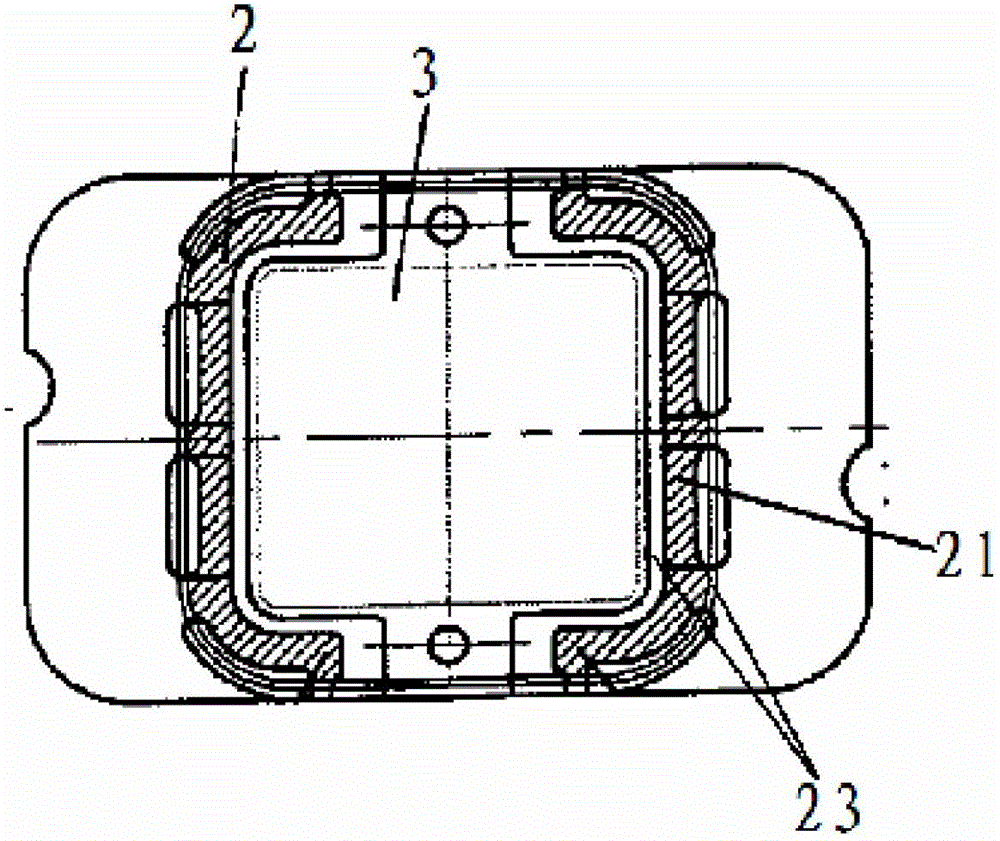

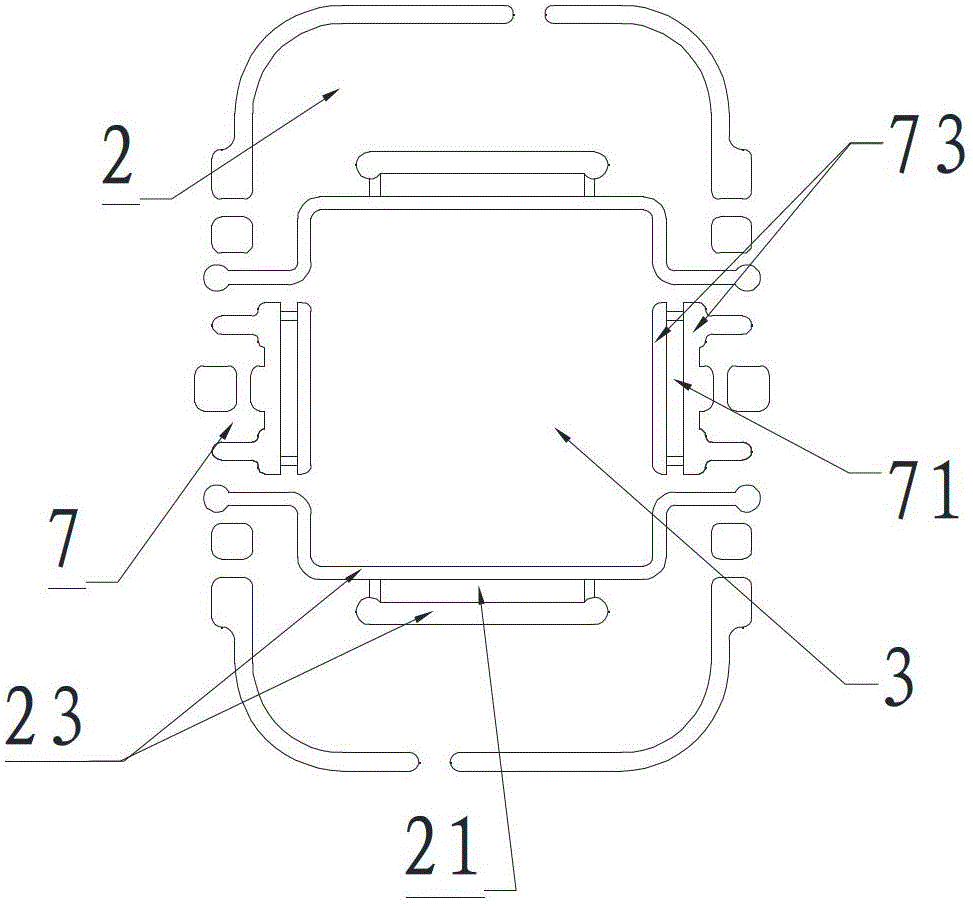

[0027] Figure 3 to Figure 6 Shown is a first embodiment of a strip for a contactless large chip smart card of the present invention. In the first embodiment, the strip includes: a chip bonding cavity 3 arranged in the central area of the strip, two lead contact pieces 2 respectively located on opposite sides of the chip bonding cavity 3, and two lead contact pieces 2 respectively located on the chip bonding cavity 3 Weld the sprue bottom plate 7 on both sides of the cavity 3 .

[0028] The two sides 23 of each lead wire contact piece 2 are hollowed out, and the middle of the two sides 23 is an upward protrusion 21, so that the described lead wire contact piece 2 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com