Interface layer treatment method for TFT (thin film transistor) dry etching process

An interface layer and process technology, applied in the field of dry engraving process, can solve the problems of long cycle, high cost, affecting the company's production capacity, etc., to achieve the effect of strengthening processing, increasing uniformity and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The adjustment of the interface pretreatment is: the RF power is increased from 3200w to 4000w, the cavity pressure is adjusted from 12Pa to 9Pa, and the mixed gas includes SF 6 (80SCCM, standard milliliters per minute), He (400SCCM, standard milliliters per minute), O 2 (800SCCM, standard milliliters per minute), the entire pretreatment time is 18 seconds.

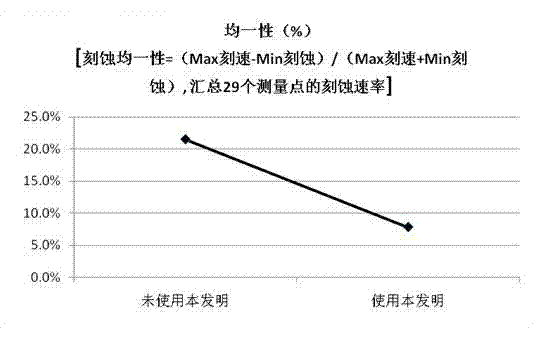

[0020] The results show that after the improved pretreatment conditions, the etching uniformity changed from 21.5% to 11.3%

Embodiment 2

[0022] The adjustment of the interface pretreatment is as follows: the RF power is increased from 3200w to 4500w, the cavity pressure is adjusted from 12Pa to 8Pa, and the mixed gas includes SF 6 (80SCCM, standard milliliters per minute), He (400SCCM, standard milliliters per minute), O 2 (800SCCM, standard milliliters per minute), the entire pretreatment time is 18 seconds.

[0023] The results show that after the improved pretreatment conditions, the etching uniformity changed from 21.5% to 10.1%

Embodiment 3

[0025] The adjustment of the interface pretreatment is as follows: the RF power is increased from 3200w to 5000w, the cavity pressure is adjusted from 12Pa to 6Pa, and the mixed gas includes SF 6 (80SCCM, standard milliliters per minute), He (400SCCM, standard milliliters per minute), O 2 (800SCCM, standard milliliters per minute), the entire pretreatment time is 18 seconds.

[0026] The results show that after the improved pretreatment conditions, the etching uniformity changed from 21.5% to 7.8%. The results are shown in figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com