Induction cooker control circuit suitable for cookers of different materials and power control method

A technology that adapts to different and control circuits. It is applied in induction heating control, induction heating, etc., and can solve problems such as power mismatch of induction cooker, reduction of working efficiency of induction cooker, and burn-in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

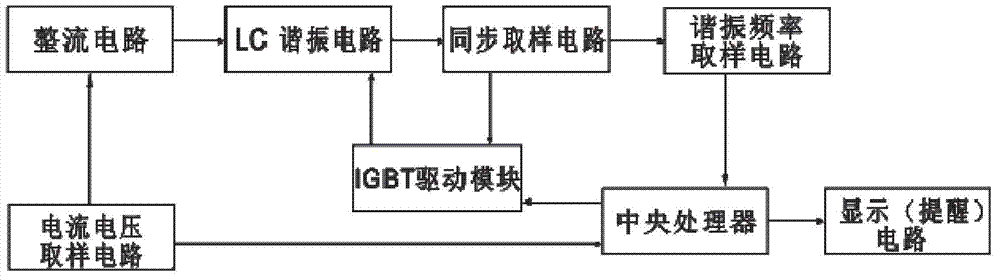

[0031] like figure 1 As shown, it is a functional block diagram of an induction cooker control circuit adaptable to different pots of the present invention, including an IGBT drive module 5, an LC resonant circuit 1 connected to the IGBT drive module 5, and a synchronous sampling circuit 2 electrically connected to the LC resonant circuit 1 , a rectifier circuit 7, a central processing unit 4 and a display circuit for power adjustment, and a sampling circuit 8 connected to the rectifier circuit 7 for collecting current and voltage signals, and the electromagnetic oven control circuit also includes a synchronous sampling circuit 2 and a synchronous sampling circuit respectively. The central processing unit 4 is connected to the resonant frequency sampling circuit 3 .

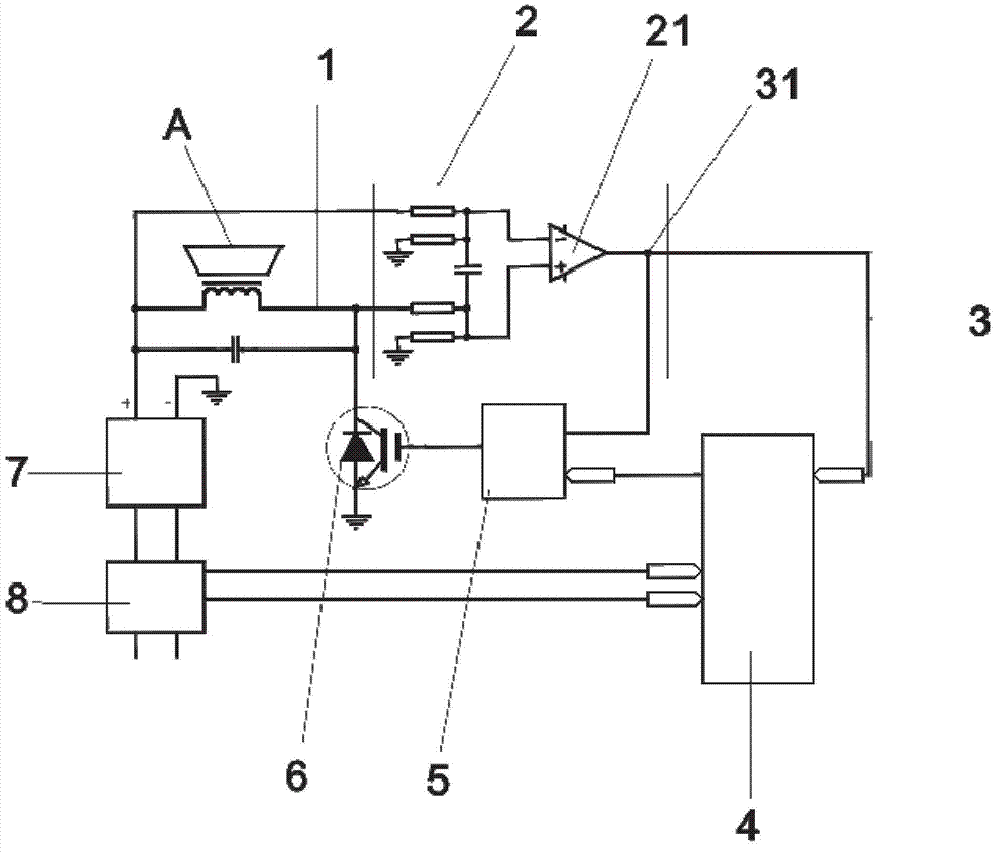

[0032] like figure 2 As shown, it is a circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com