Deformation Strengthening Device for Generator Guard Ring Blank

A deformation strengthening and generator technology, applied in the field of metal plastic extension, can solve the problems of large tonnage of die forging equipment, small number of forming cones, anisotropy of performance, etc., achieve high blank precision, reduce machining allowance, simplify The effect of mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

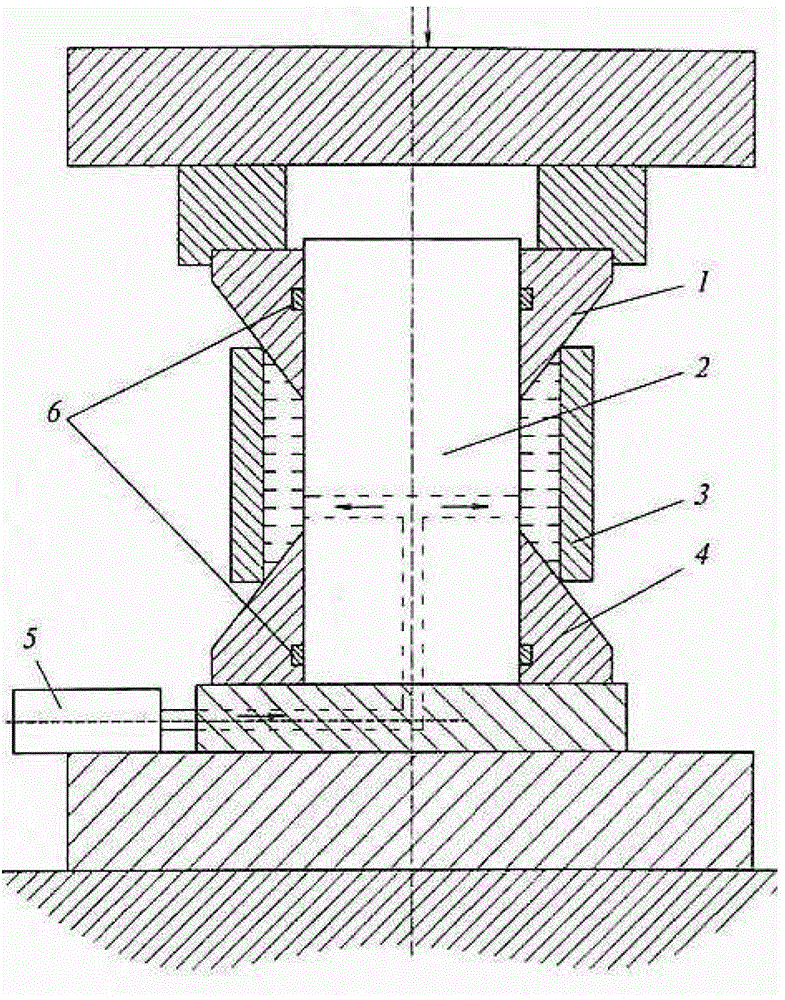

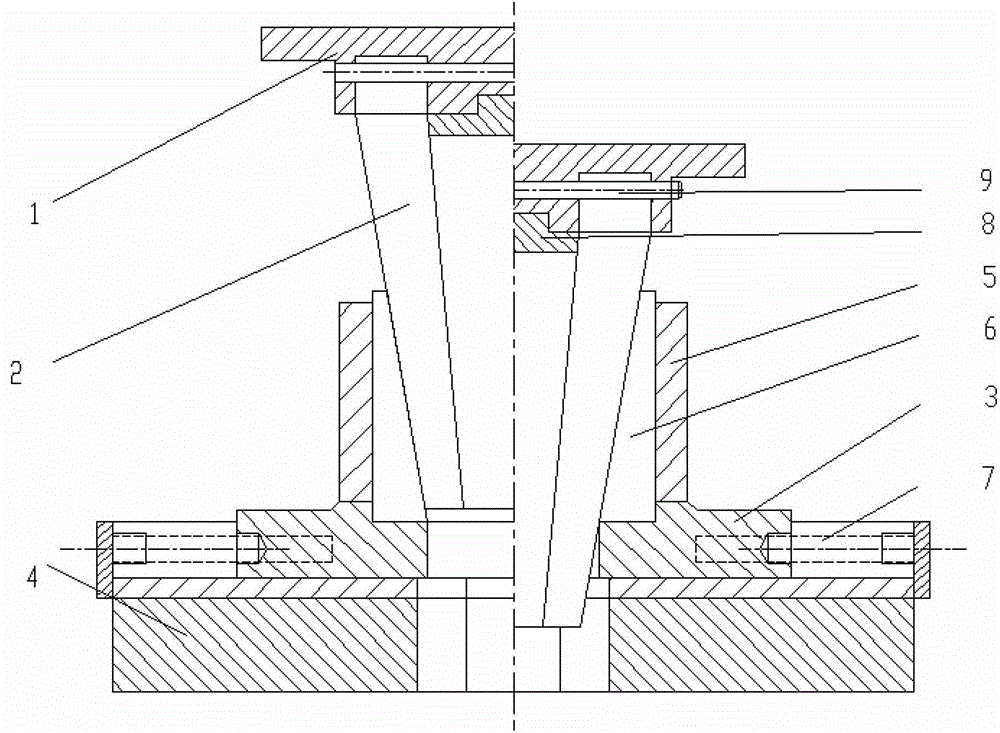

[0029] Such as figure 2 As shown, this embodiment includes: a press machine (not shown) arranged in sequence from top to bottom, an upper support plate 1, a cone 2, a support frame 4, and a slider 3 horizontally slidably arranged on the support frame 4, wherein : The retaining ring blank 5 to be processed is set on the slide block 3, a wedge combination is arranged between the cone 2 and the blank 5, and the taper of the inner surface of the wedge combination matches the taper of the outer surface of the cone 2.

[0030] A return spring 7 is provided between the slider 3 and the support frame 4 .

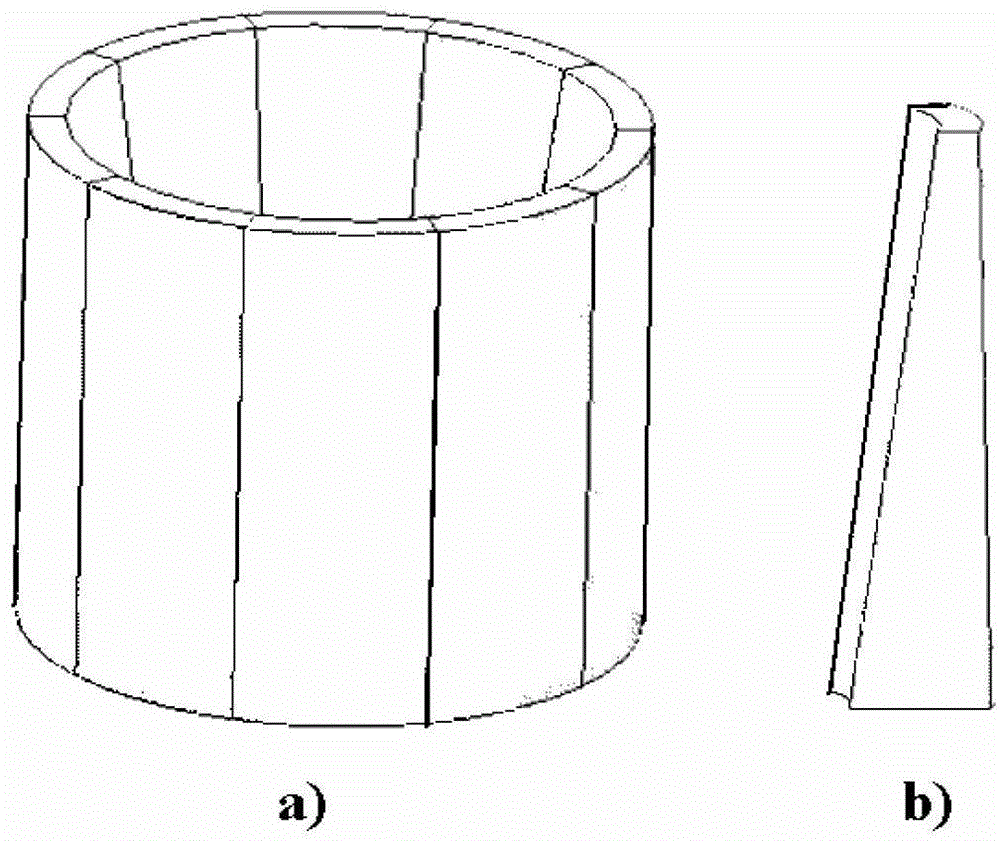

[0031] The wedge assembly fits the inner surface of the retaining ring blank 5 and is evenly distributed in the circumferential direction, and the height of the wedge assembly is greater than the height of the retaining ring blank 5 .

[0032] The wedge combination is composed of 8 to 12 wedges 6 with a fan-shaped block structure.

[0033] Described locating pin 8 and the taper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com